Fracturing fracture-forming technique and method for shale

A shale and fracture-making technology, applied in the direction of earthwork drilling, mining fluid, wellbore/well components, etc., can solve the problems of blocked seepage channels, biofilm hindering gas flow, slow liquid volatilization speed and water lock, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific embodiments.

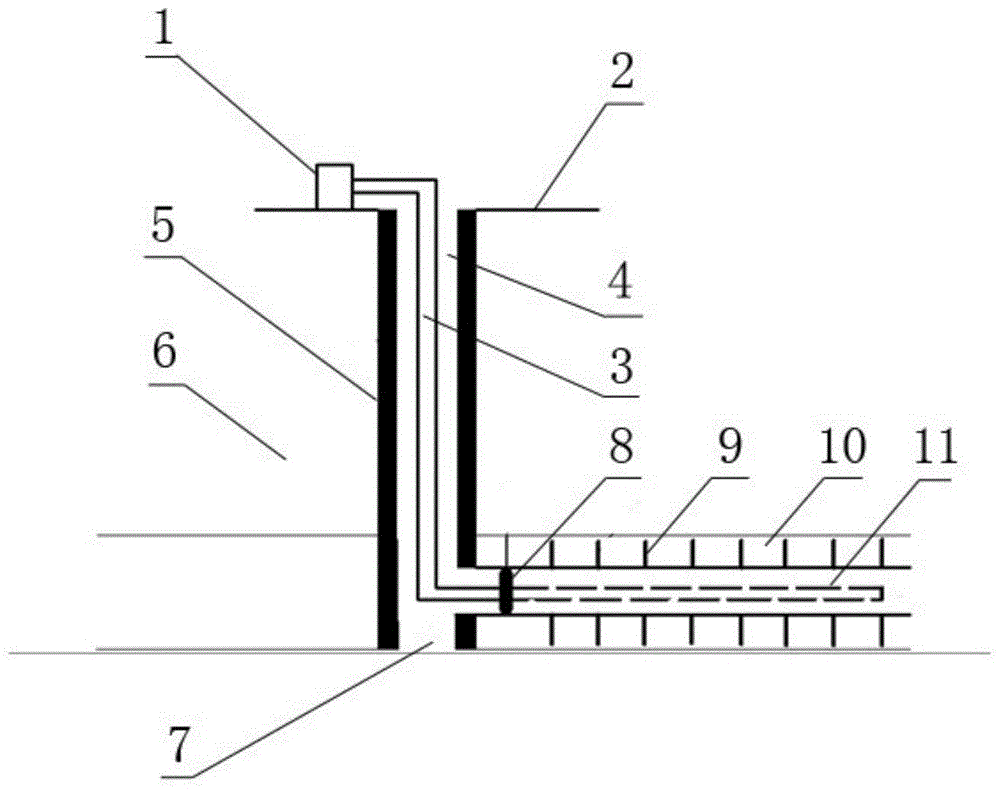

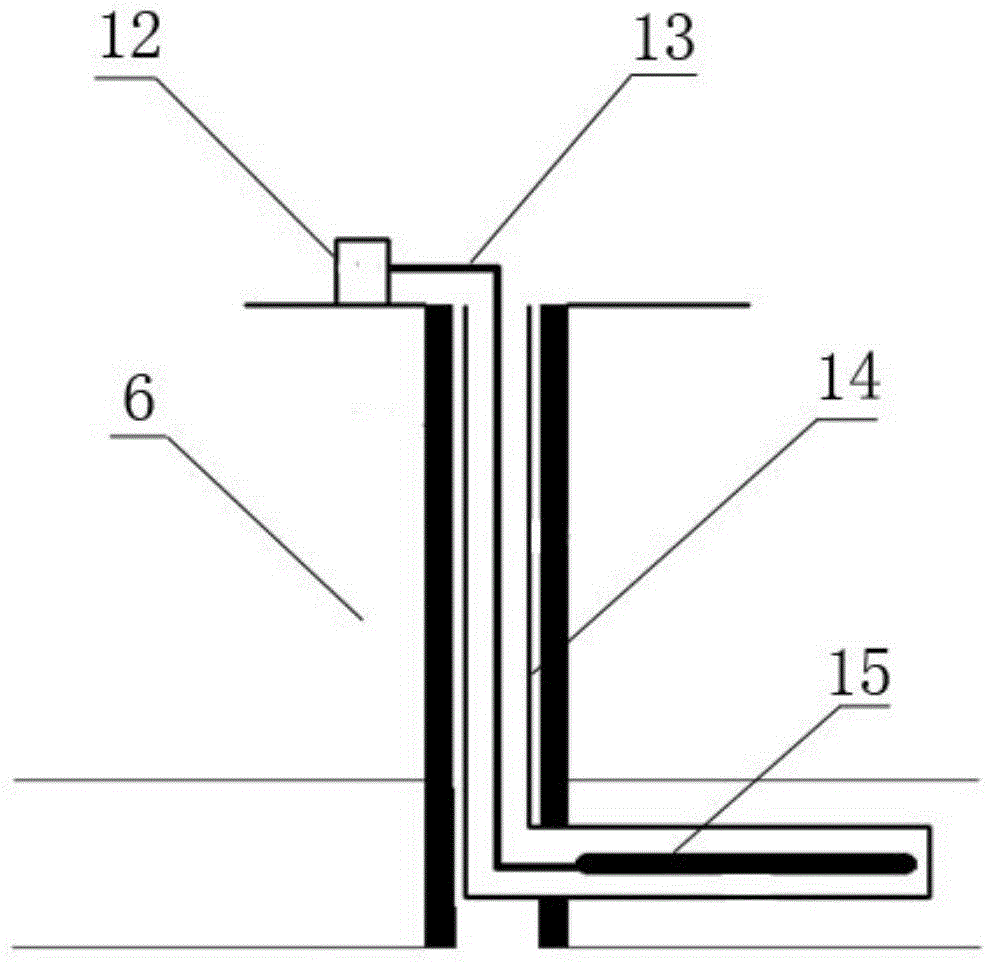

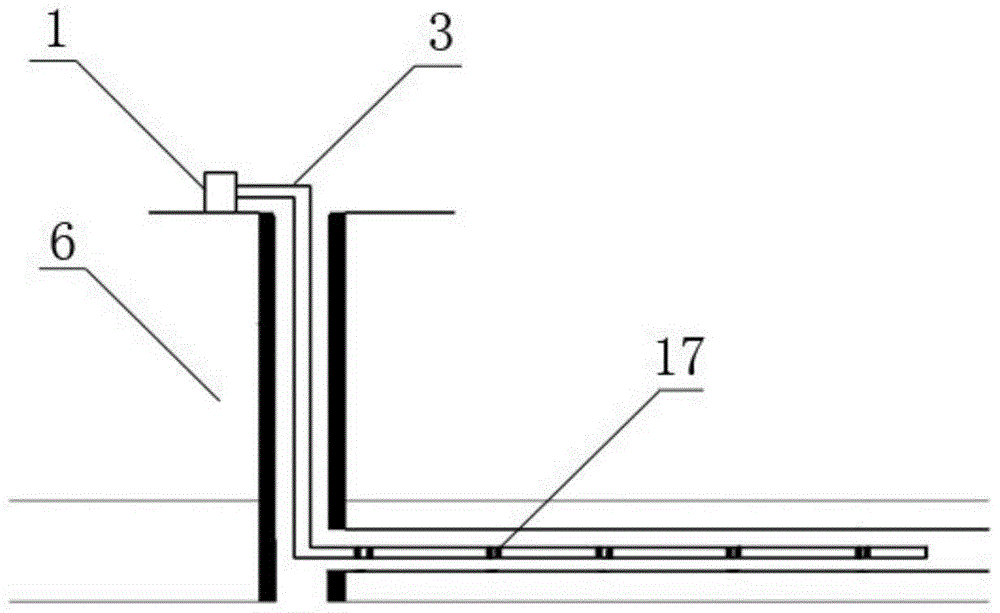

[0028] refer to Figure 1-3 , a technology and method for shale fracturing and fracture creation, comprising the following steps:

[0029] Step 1: There are shale wells and pump set 1 on the ground 2. The pump set 1 can provide high pump pressure and can pump microwave high-temperature heating heating materials and subsequent liquid nitrogen into the formation. NT-1201 from S&S company can be used -DF pump, the power is 1103.25kW, the maximum working pressure is 70.0MPa, and the maximum displacement is 862.24L / min. The microwave high-temperature heating heating material is prepared by compounding MoSi2 and other microwave strong absorption materials. The use form of MoSi2 includes powder, slurry or plate shape. Other microwave strong absorption materials compounded with it are SiC, A mixture of one or more of AlN, C, CuO, Fe3O4, a shale well includes a wellbore 4, a well ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com