Tunnel secondary lining arch crown concrete filling machine and construction method thereof

A construction method and concrete technology, which are applied in tunnel lining, tunnel, earth-moving drilling, etc., can solve the problems of secondary lining concrete structural defects, concrete fluidity loss, hidden danger of tunnel operation, etc., and achieve good practicability, economic benefits and Social benefits, improved production efficiency, and low input costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

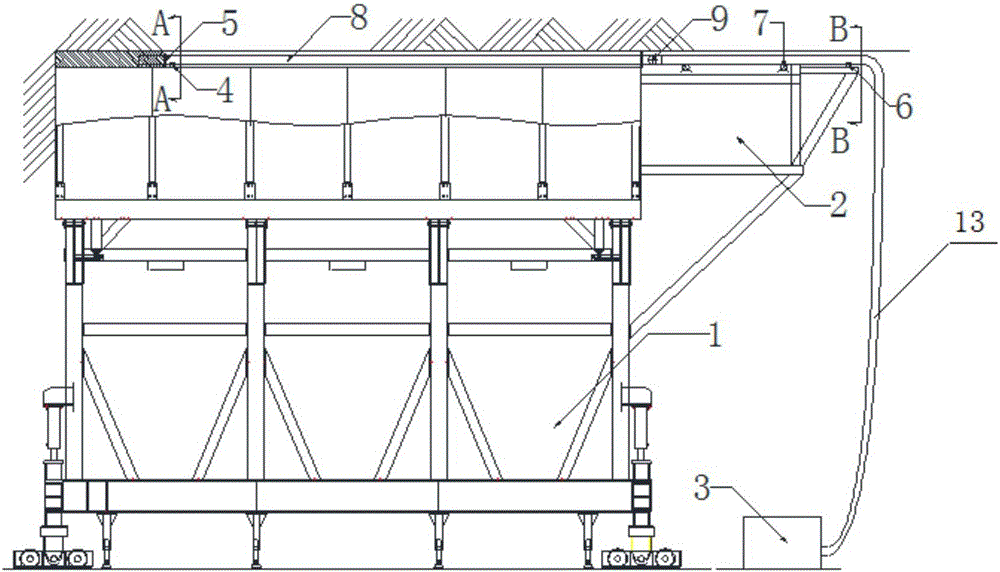

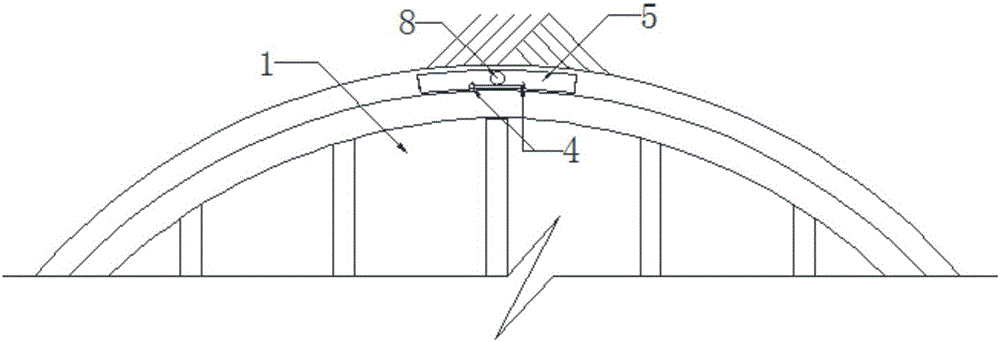

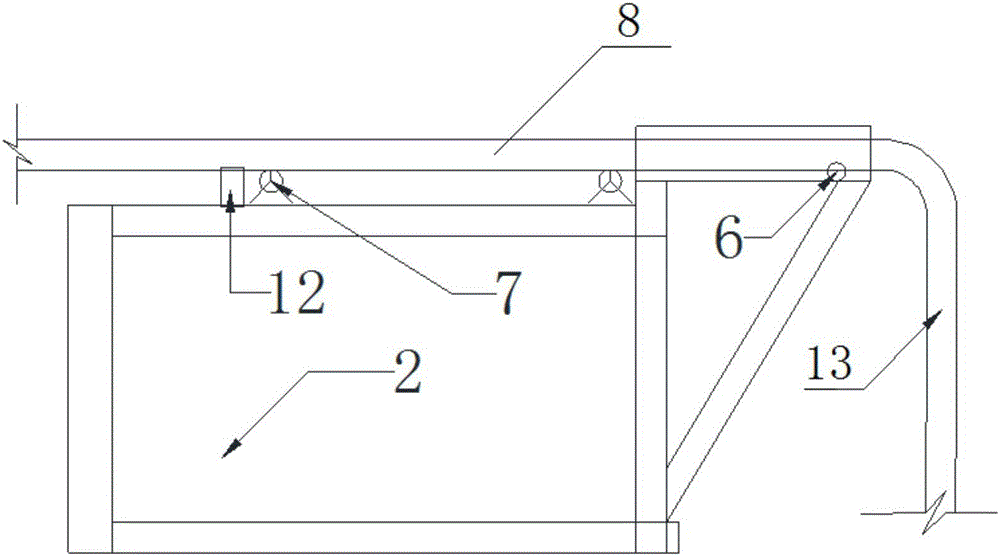

[0033] Such as Figure 1-5 The concrete pouring machine for the second lining vault of the tunnel shown mainly includes a concrete pump 3, a concrete delivery pipe 8 and a pouring machine support 2. The concrete delivery pipe 8 is connected by multiple steel pipes and is connected to the concrete pump 3 through a delivery hose 13 connection. A pair of walking wheels are installed at the front and rear ends of the concrete delivery pipe 8, the front walking wheel 4 rides on the vault formwork, the rear walking wheel 6 is placed on the track of the pouring machine bracket 2; the pouring machine bracket 2 is attached to the lining trolley 1 , The support of the pouring machine is also provided with rollers 7 and a motor 11, starting the motor to rotate the rollers can make the concrete conveying pipe walk back and forth, the roller 7 and the rear travel wheel 6 are equipped with guide wheels 10 on both sides.

[0034] A brake 12 is provided in the middle of the concrete conveying p...

Embodiment 2

[0037] The concrete pouring construction method of the second lining and vault roof of the tunnel includes the following steps:

[0038] (1) Extend the concrete delivery pipe 8 of the concrete pouring machine for the second tunnel lining vault from the reserved hole of the end template to the top;

[0039] (2) When pouring concrete, the concrete delivery pipe 8 moves back and forth on the support 2 of the pouring machine and retreats with the progress of the pouring construction; remove part of the steel pipe of the concrete delivery pipe 8 exiting the end formwork and continue pouring concrete;

[0040] (3) When the last section of steel pipe of the concrete conveying pipe 8 is retracted outside the end formwork, install the head formwork with the concrete pump pipe stop valve 9 and connect the concrete conveying pipe 8 with the stop valve 9 to continue pouring concrete and constant pressure Close the concrete pump pipe shut-off valve after minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com