Double-end face mechanical sealing device

A sealing device and mechanical technology, which is applied in the field of mining machinery and thermal power generation machinery and equipment, can solve the problems of loss of compensation function, poor working condition of the sealing device, and shortened service life, so as to promote the improvement of production efficiency, prolong the maintenance period, The effect of improving usage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

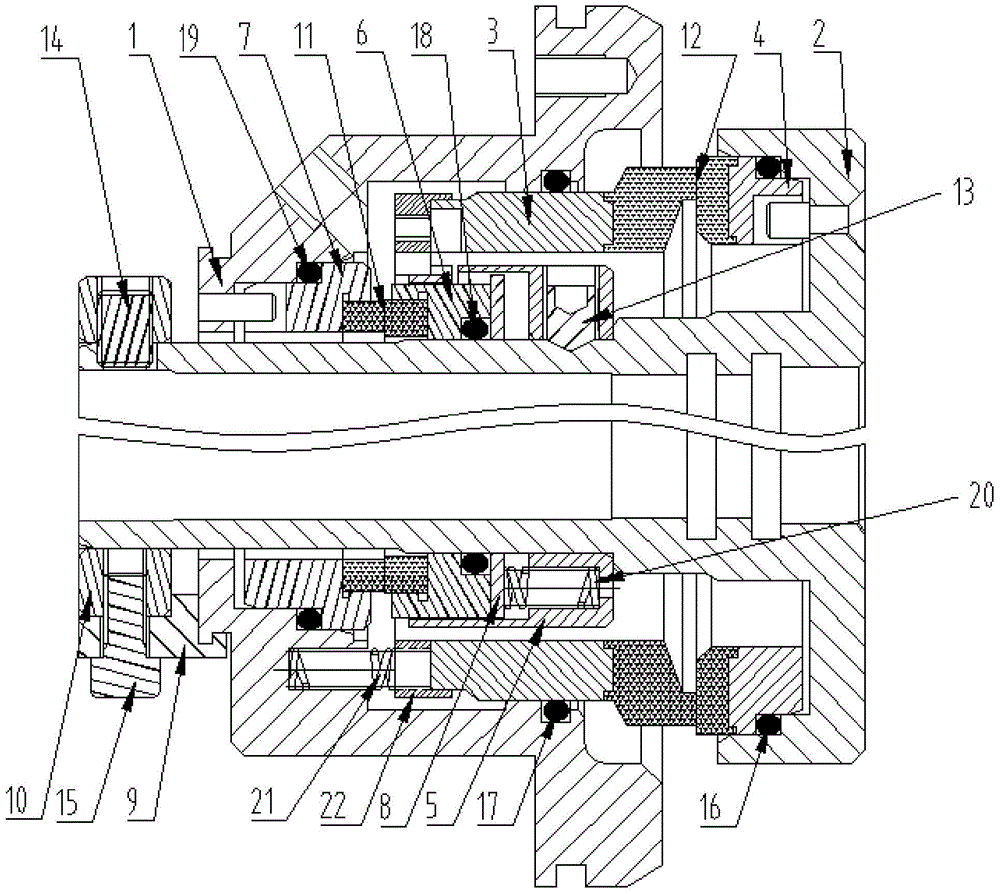

[0013] The implementation of the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to facilitate the understanding of the technical solution by those skilled in the art.

[0014] The preparation work before the implementation, the parts of the double-end mechanical seal device, the related equipment, tooling tools, lubricating oil (grease), wiping materials (cotton yarn, white cloth, silk, etc.) and other auxiliary materials must be clean, The parts of the double-end mechanical seal device need to be chamfered and rounded. The chamfers of the shaft and the sealing end cover should be smoothed. Wipe with white silk or soft gauze; check whether the fitting dimensions, roughness, and parallelism of each part meet the requirements, check whether the model, specification, and quantity of the mechanical seal meet the requirements, and check whether all parts (especially the seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com