Method for establishing internal leakage model of vane type continuous rotary electro-hydraulic servomotor

An electro-hydraulic servo and vane-type technology, applied in the direction of electric digital data processing, special data processing applications, instruments, etc., can solve the problems of great difference, staying, and not considering the key parts of the motor, etc., to achieve low-speed performance improvement and overall structure Optimization and improvement, the effect of important practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

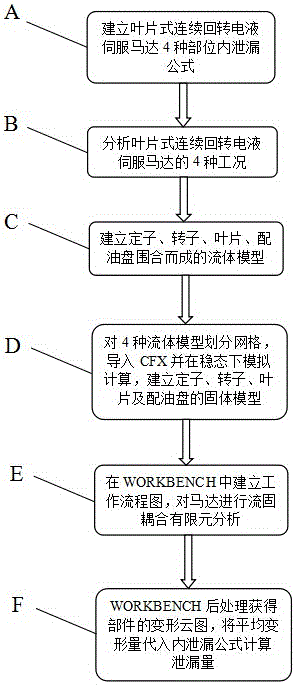

Method used

Image

Examples

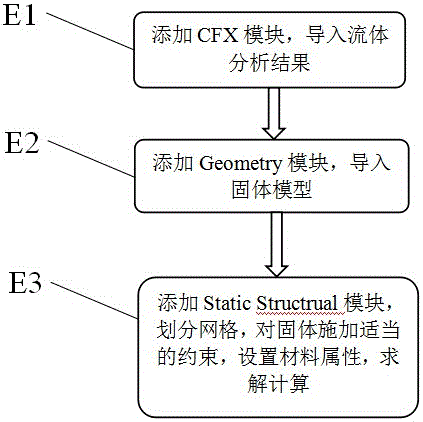

Embodiment Construction

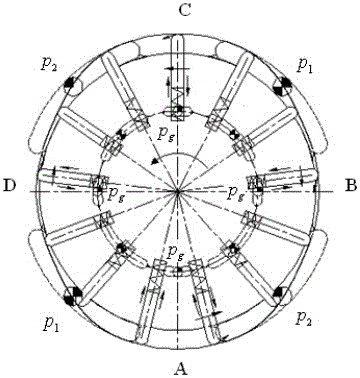

[0018] In order to ensure the flexible operation of the blade type continuous rotary electro-hydraulic servo motor, there must be a certain gap between the relative sliding surfaces of each component. When these gaps are under the action of the pressure difference between the high and low pressure chambers, internal leakage will inevitably occur, and the internal leakage mainly includes:

[0019] (1) Leakage between the top of the blade and the inner surface of the stator;

[0020] (2) Leakage between the end surface of the blade and the working surface of the oil distribution plate;

[0021] (3) Leakage of the matching gap between the blade and the blade groove;

[0022] (4) Leakage between the end face of the rotor and the working face of the oil distribution plate.

[0023] After careful analysis and reasonable simplification, these four kinds of leakage can be classified as parallel plane gap leakage.

[0024] The parameters of the vane type continuous rotary electro-hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com