Method for glue pouring of battery box of electric vehicle

A technology for electric vehicles and battery boxes, which is applied in the manufacture of secondary batteries, battery pack components, battery boxes/coats, etc., and can solve the problems of shock absorption, explosion-proof and flame-retardant performance of electric vehicle power batteries, time-consuming and labor-intensive problems, and work efficiency. Low-level problems, to achieve the effect of improving explosion-proof and flame-retardant performance, firm connection, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

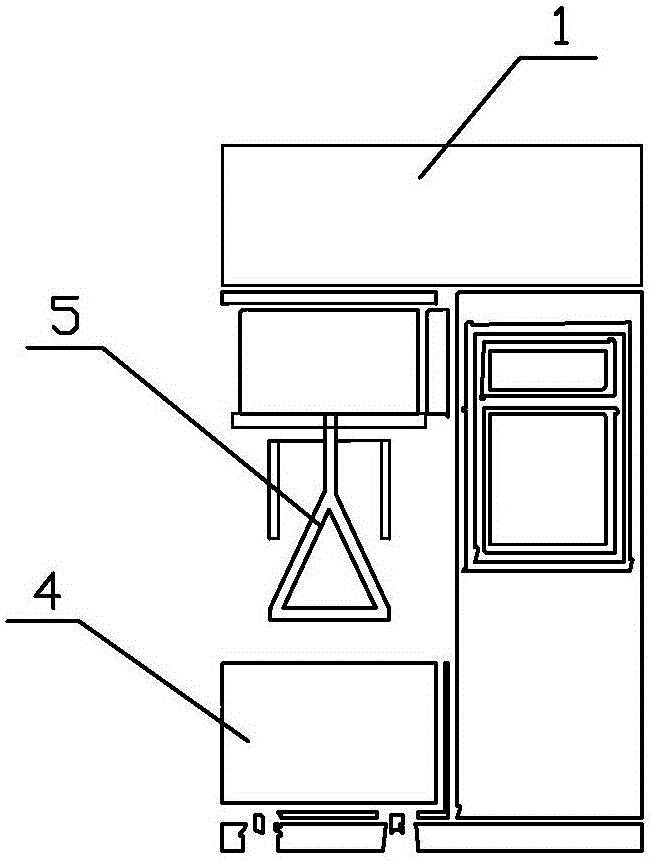

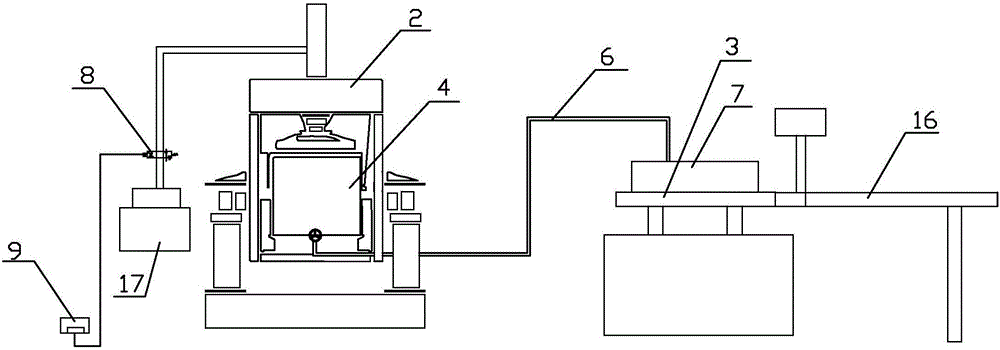

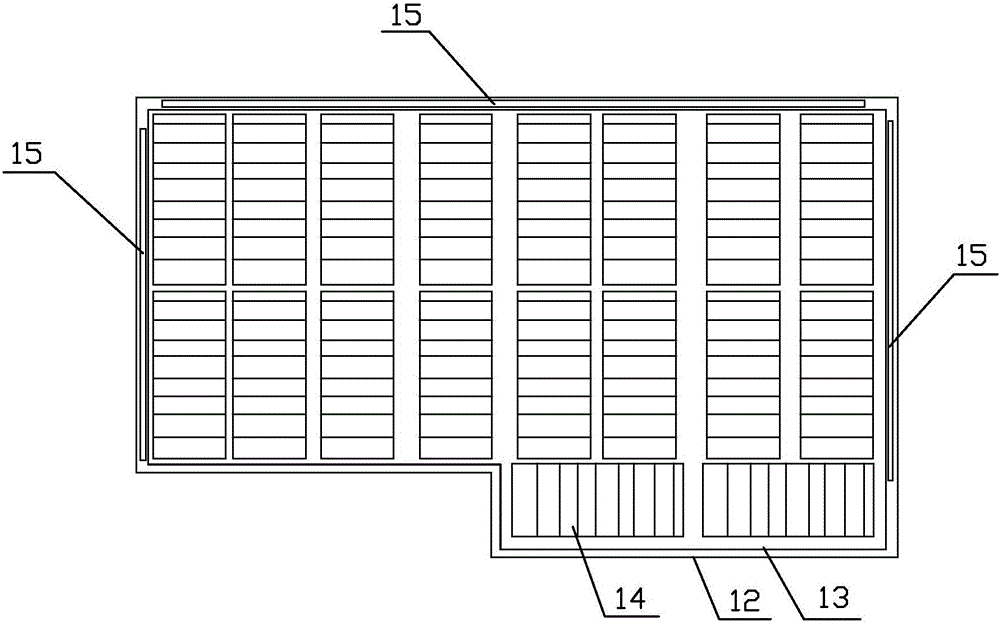

[0020] Embodiment: The electric vehicle battery box glue filling method of this embodiment needs to use the electric vehicle battery box glue filling system, such as figure 1 , figure 2 As shown, the electric vehicle battery box glue filling system includes a mixer 1, a hydraulic discharger 2 and an electronic scale 3, the mixer 1 is a low-speed mixer, the electronic scale is installed on the roller assembly line 16, and the hydraulic discharger 2 is installed on the roller assembly line Nearby, mixing bucket 4 is placed on the base of mixer 1, and mixer 1 has the stirring core 5 that can lift, and stirring core 5 is positioned at the top of mixing bucket 4, and timer is installed on mixer 1. Four pulleys are installed at the bottom of the bucket of the mixing bucket 4, and the bottom of the mixing bucket 4 has a discharge port, and a valve is installed on the discharge port. When the mixing bucket 4 is placed on the bottom plate of the hydraulic discharge machine 2, the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com