Dedicated thyristor module for soft starters

A soft starter, thyristor technology, applied in starter parts, electric solid devices, semiconductor devices, etc., can solve the problems of large thyristor volume, high heat sink thermal resistance, and high overall cost, so as to improve product reliability and reduce Thermal resistance, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

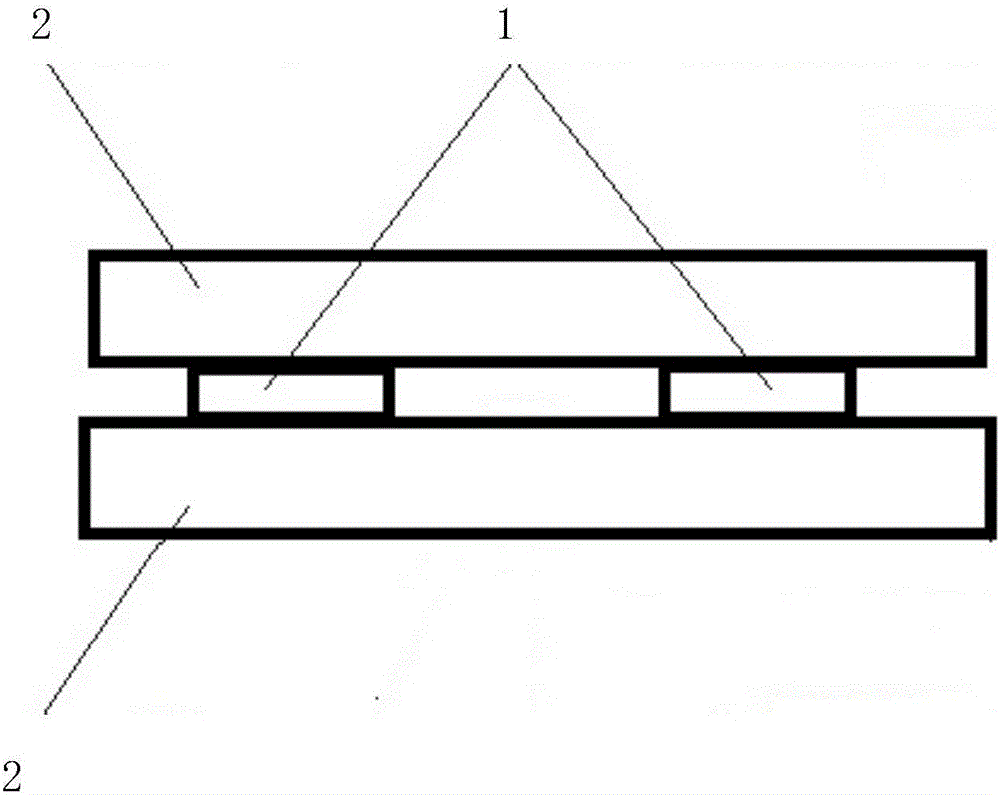

[0011] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as figure 1 As shown, a thyristor module dedicated to a soft starter includes two thyristors 1, two radiators 2, and a sealing ring 3. The algorithm of the radiator is as follows:

[0012] W=K*Q*T / β

[0013] Among them: W: the weight of the radiator; K: the reliability factor; Q: the heating power of the thyristor; T: the time for the thyristor to complete when the motor is started; β: the specific heat capacity of the radiator;

[0014] The weight of the radiator is calculated from the above formula, and then the two thyristors are connected in reverse parallel and directly crimped together according to the required shape. The thyristor and the radiator are packaged together in an insulating case, and the radiator is directly connected to an external power terminal and a control terminal.

[0015]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com