Hydraulic system for driving a vibratory mechanism

一种液压系统、振动机构的技术,应用在液压系统领域,达到提高燃料效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In the following, various aspects of the disclosure will be described to illustrate (but not limit) the disclosure, taken in conjunction with the accompanying drawings, wherein like numerals refer to like elements, and variations of the described aspects are not limited to the particular illustrated embodiments, but rather Other variations of the present disclosure can be applied.

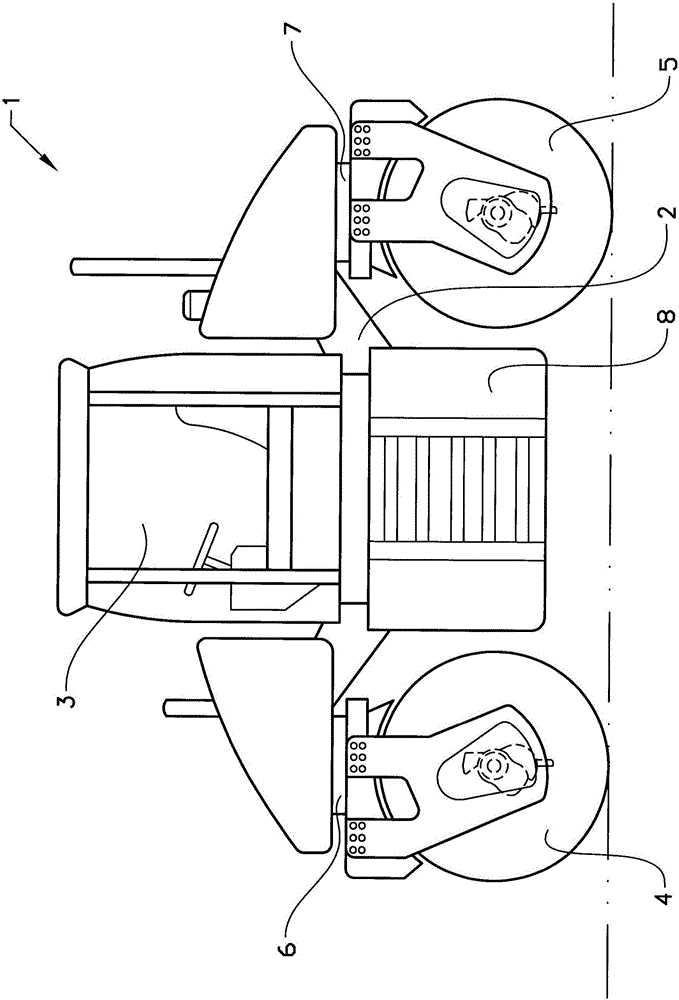

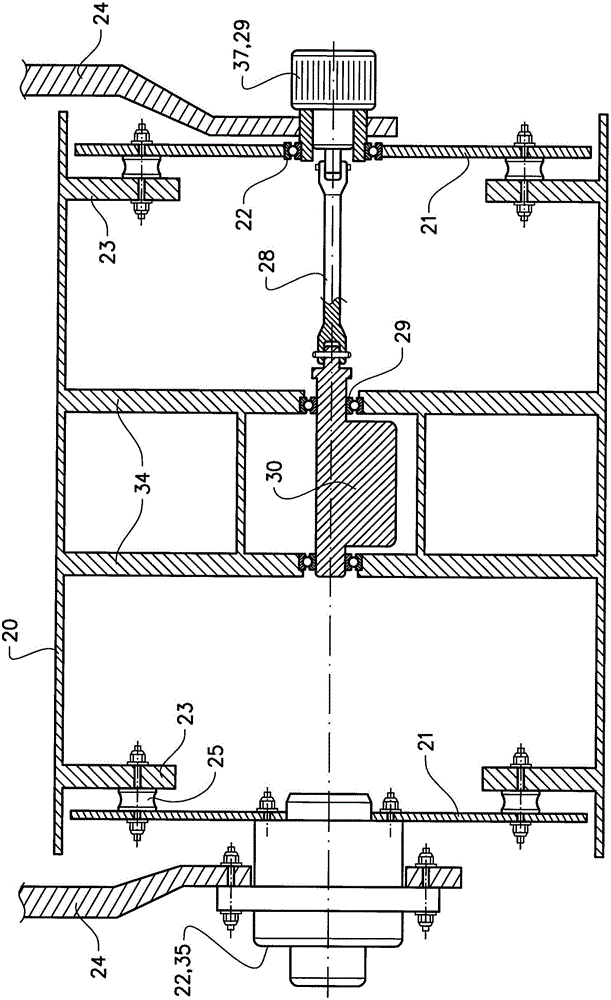

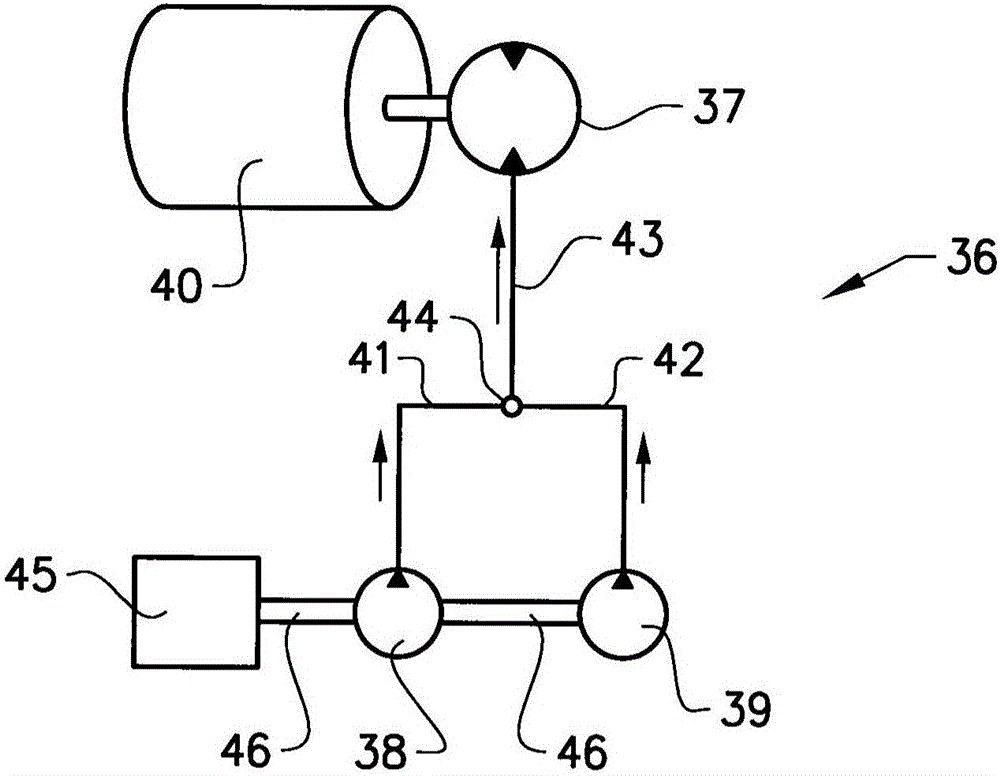

[0036] Steel vibrating rollers and drums apply force which enhances compaction. The vibrating roll has an internal eccentric weight that rotates on an axis. This rotating eccentric weight causes the roller to move in all directions, but an active part of it is up and down. Vibratory forces are the rapid up and down motions that cause concrete aggregates and soil particles to move. Aggregate in motion tends to reorient itself more easily so the material compacts more easily under the weight of the rollers. Vibration is a particularly effective means for aggregate or granular materials like...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com