A kind of wet-mixing preparation method of nickel-based high-temperature olefin alloy powder

A high-temperature alloy and olefin alloy technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of poor dispersion, easy to react with superalloy matrix elements, and affect the mechanical properties of the alloy, and achieve the effect of fine powder particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

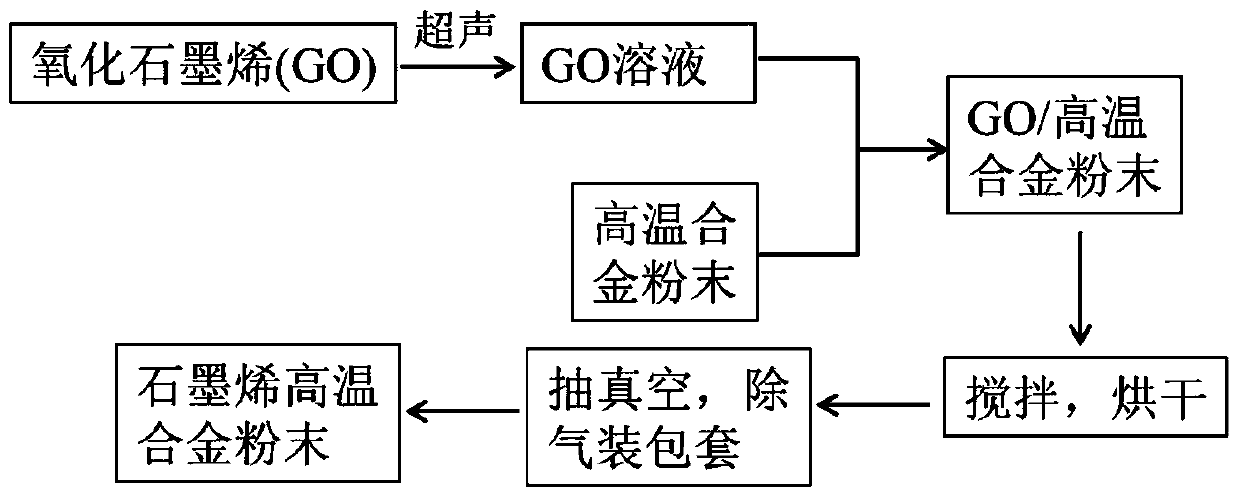

Method used

Image

Examples

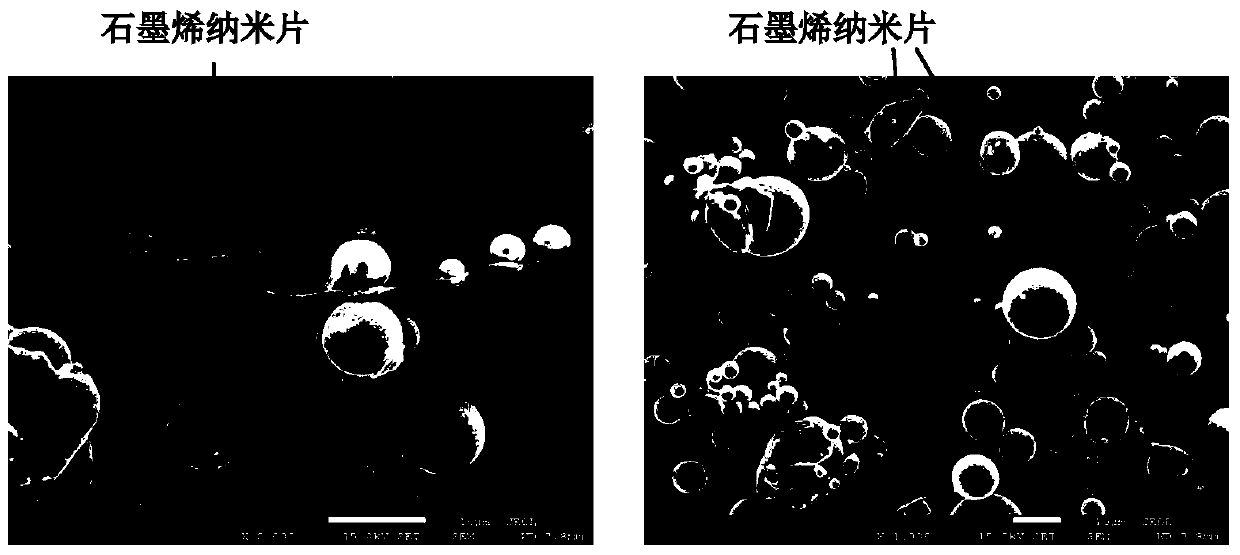

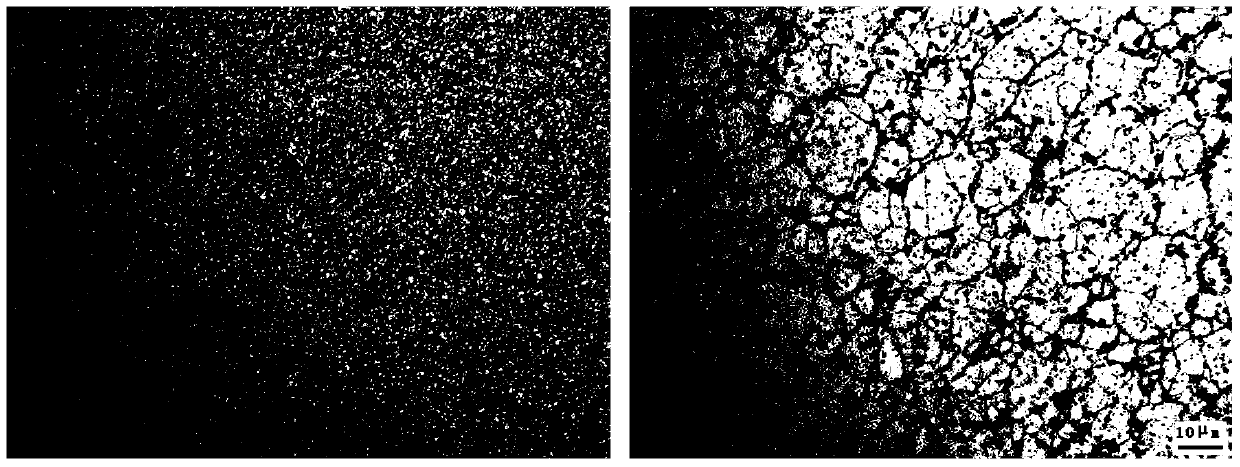

Embodiment 1

[0030] The powder superalloy was smelted in a ZG25 vacuum induction furnace to prepare the FGH96 powder superalloy master alloy ingot. Then, 20 kg of superalloy powder was prepared by argon atomization method (AA method), and the powder was sieved to obtain FGH96 superalloy powder with a particle size of -250 mesh. Graphene oxide nanosheets were prepared by redox method. 1g of graphene oxide nanosheets was divided into 2 parts on average, dissolved in 300ml of alcohol respectively, and the graphene oxide solution was ultrasonically treated with a cell pulverizer. Ultrasonic working time for 40 minutes. The graphene oxide solution after sonication was left to stand for 2 hours, and the excess alcohol on the upper part of the container was removed. Evenly divide the prepared 2kg of FGH96 into 10 parts, each with 200g of powder, add the powder into the graphene oxide solution, and use a mechanical stirrer to continuously stir. Fully stir the graphene oxide / superalloy mixed powd...

Embodiment 2

[0032]The ZG25 vacuum induction furnace was used to smelt the powder superalloy, and the U720 superalloy master alloy ingot was prepared. Then, 10 kg of superalloy powder was prepared by argon atomization method (AA method), and the powder was sieved to obtain U720 superalloy powder with a particle size of -300 mesh. Graphene oxide nanosheets were prepared by the redox method, and the graphene oxide nanosheets with a weight of 360g were divided into 6 parts on average, dissolved in 300ml alcohol respectively, and the graphene oxide solution was ultrasonically treated with a cell pulverizer, and the ultrasonic working time for 30 minutes. The graphene oxide solution after sonication was left to stand for 2 hours, and the excess alcohol on the upper part of the container was removed. The prepared 6kg U720 was evenly divided into 6 parts, each with 1kg powder, and the powder was added to the graphene oxide solution, and a mechanical stirrer was used to continuously stir. Fully ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com