Core insertion machine for earpieces

A technology of eyeglass legs and ferrules, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

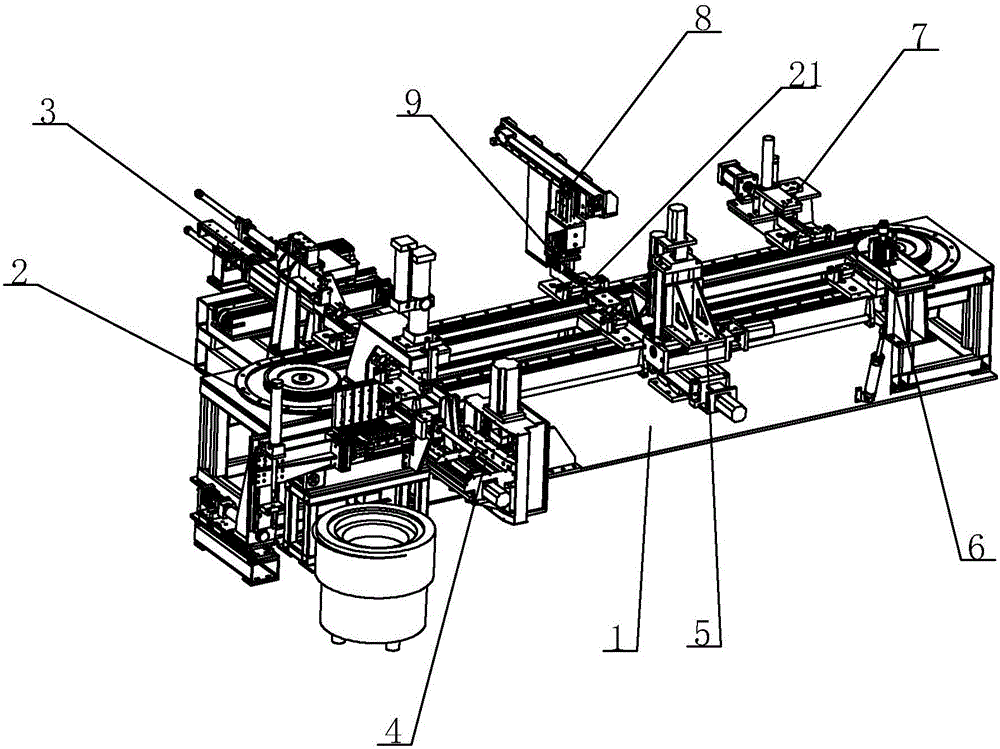

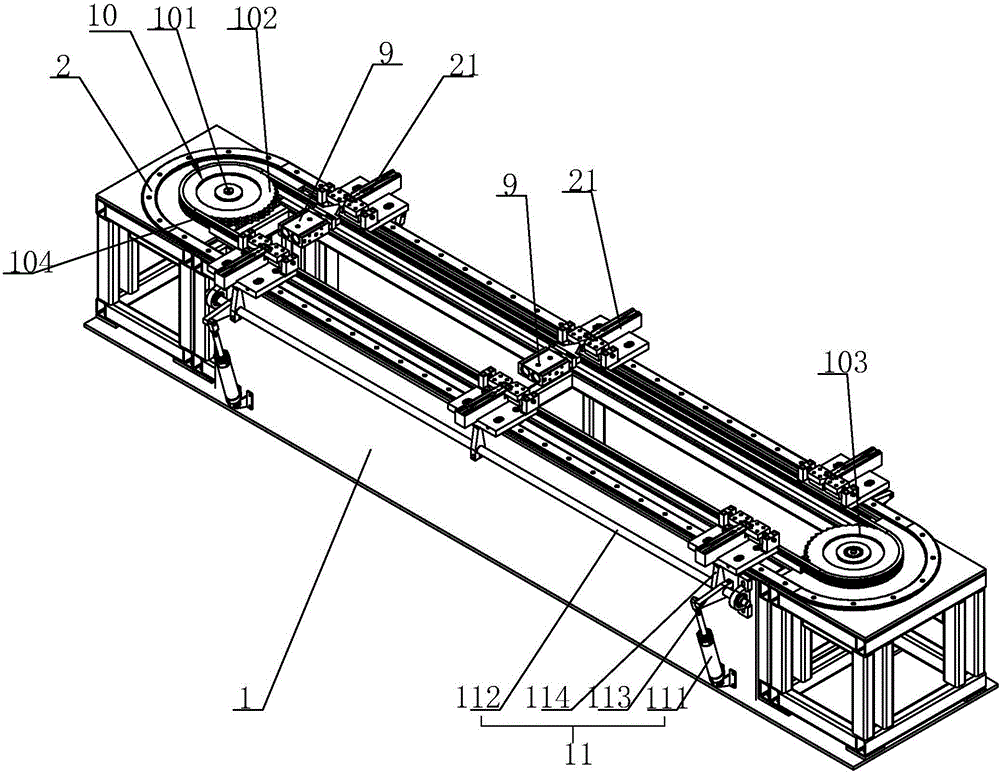

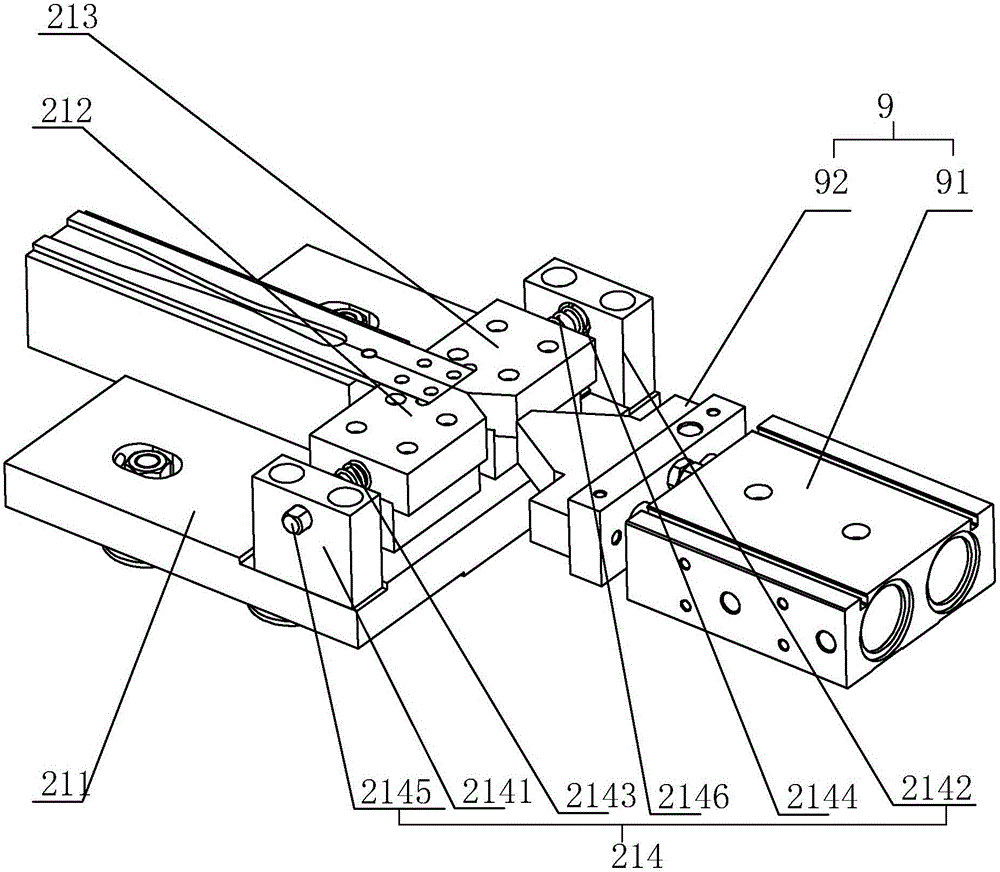

[0019] Refer to attached Figure 1 to Figure 3 A spectacle pin core insertion machine of the present invention will be further described in detail.

[0020] A spectacle pin core inserting machine, comprising a frame 1, on which a closed conveying track 2 is arranged, and a spectacle pin feeding mechanism 3 and a pin feeding mechanism are arranged on the periphery of the conveying track 2 in sequence 4. Waste removal mechanism 5, calender mechanism 6, cover glue mechanism 7 and discharge mechanism 8, said conveying track 2 is provided with a plurality of clamping devices 21 for clamping spectacle feet, said clamping device 21 The gaps are distributed on the conveying track 2 and correspond to the spectacle temple feeding mechanism 3, the pin feeding mechanism 4, the waste removing mechanism 5, the calendering mechanism 6, the cover glue mechanism 7 and the discharging mechanism 8 respectively. 1 is also provided with a conveying driving device 10 that drives the clamping devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com