Novel pasting equipment for toilet paper parcel double-faced adhesive sticker tape

A paper bag and adhesive tape technology, applied in the new type of paper bag double-sided self-adhesive tape pasting equipment, pasting equipment field, can solve the problem of complex structure, accidentally dropped to the ground, can not be used with automatic suction. Paper bag production line, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

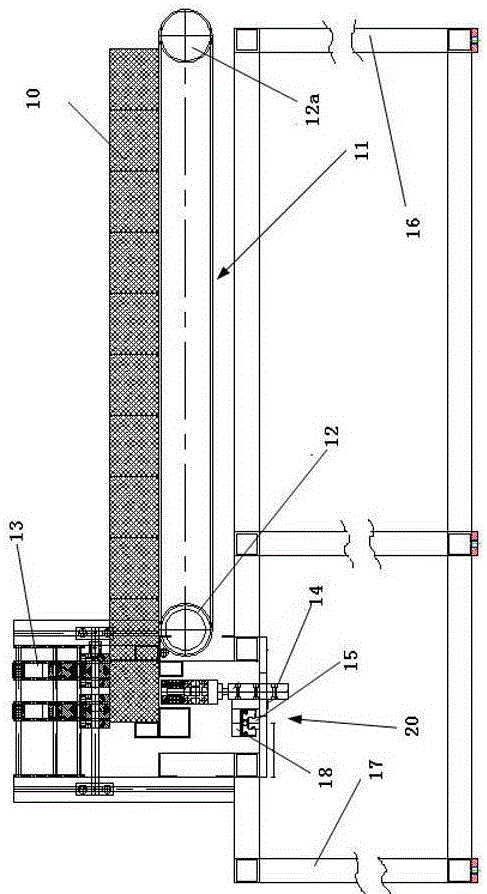

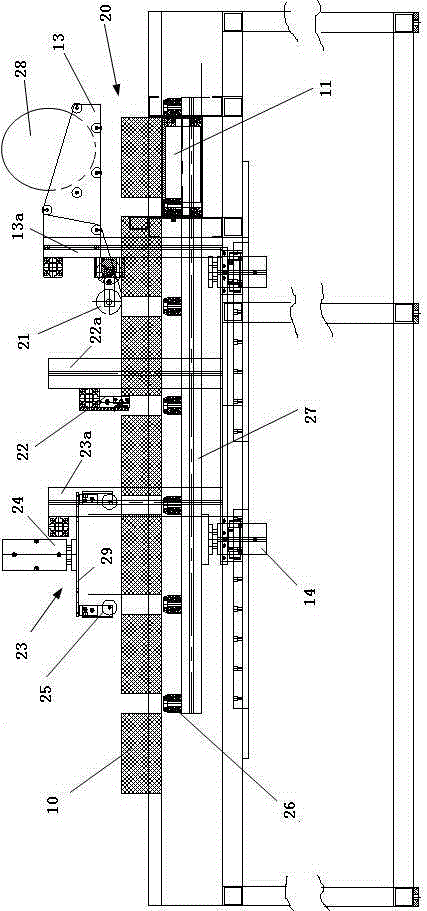

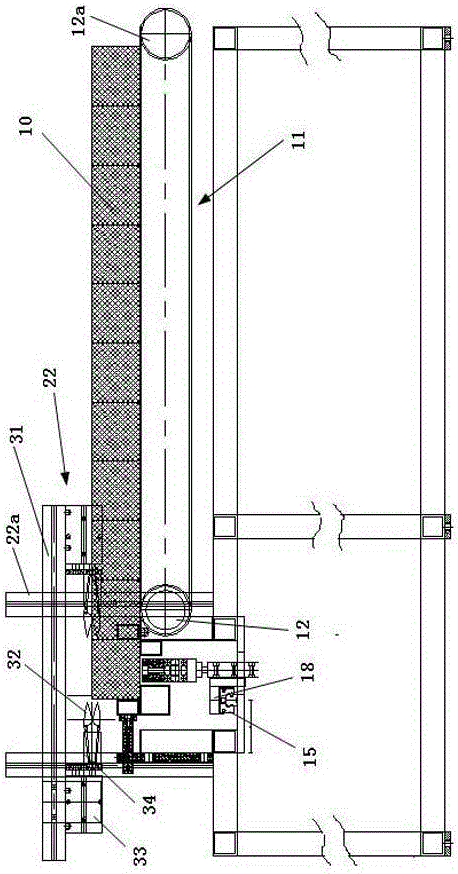

[0022] In order to save space, the belt conveyor and step conveyor of this equipment are connected vertically on the horizontal plane, and the end of the belt conveyor is connected with the starting point of the step conveyor. , In the following description, the belt conveyor is conveyed from right to left, the running direction of the step conveyor 20 is the front and rear direction, and the conveying direction is to convey the paper pack from far to near direction, on the left and right of the step conveying direction Both sides are the sides of the stepper conveyor.

[0023] The technical scheme of the present invention is a new type of paper-packing double-sided adhesive tape pasting equipment. The technical scheme of the present invention will be described below with reference to the accompanying drawings. Among them, figure 1 It is a schematic cross-sectional view of the side of the belt conveyor and the sticker frame of the stepping conveyor. figure 2 It is a side view o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com