Bonded ferrite magnetic powder, bonding magnet and preparation method thereof

A ferrite magnet and bonded magnet technology, applied in chemical instruments and methods, magnetic materials, magnetic objects, etc., can solve the problems of high viscosity of magnetic powder and difficulty in filling amount of magnetic powder exceeding 91wt.%

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

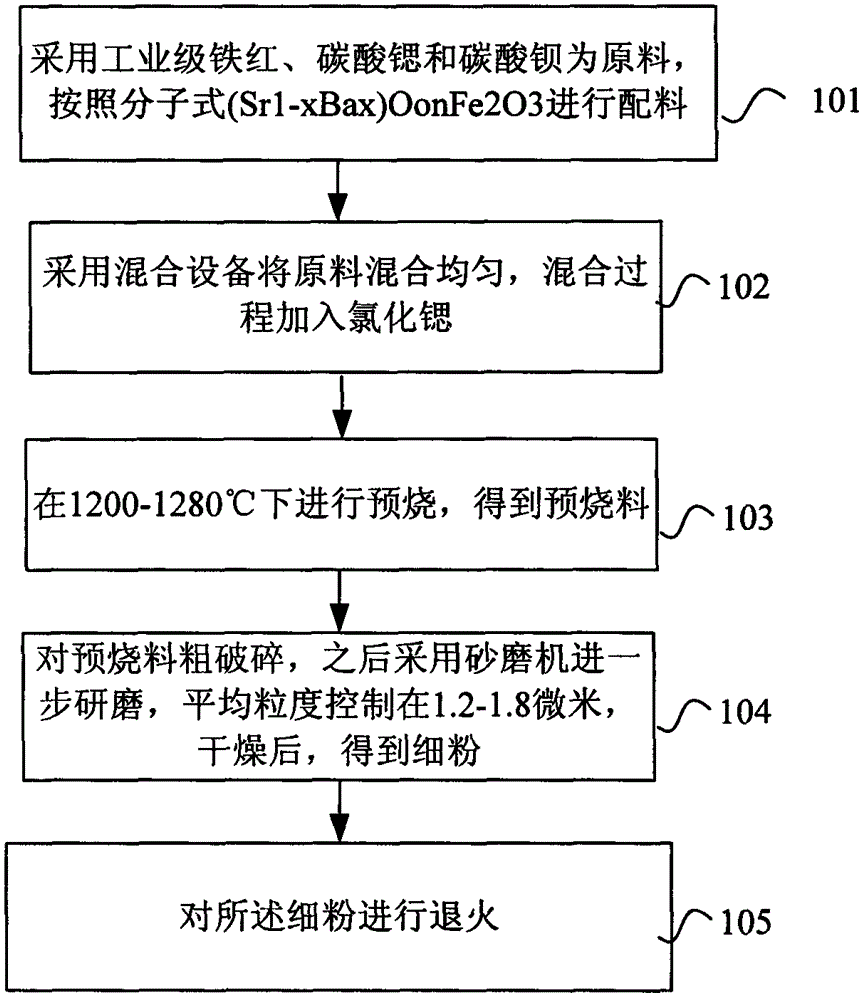

[0031] The embodiment of the present invention provides a kind of preparation method of above-mentioned bonded ferrite magnetic powder, such as figure 1 shown, including the following steps:

[0032] Step 101, using industrial grade iron red, strontium carbonate and barium carbonate as raw materials, according to molecular formula (Sr 1~ x Ba x )O·nFe 2 o 3 For ingredients,

[0033]Wherein, n represents the molar ratio, satisfying n=6.11~6.30; 0.10≤x≤0.20.

[0034] Step 102, mixing materials: using a mixing device to mix the raw materials evenly, and adding 0.5-4.0% strontium chloride by weight of the iron red raw materials during the mixing process.

[0035] Step 103, pre-burning: pre-burning at 1200-1280°C to obtain pre-fired material;

[0036] Step 104, Grinding: Use a ball mill to coarsely crush the calcined material, and then use a sand mill to further grind, the average particle size is controlled at 1.2-1.8 microns, and after drying, a fine powder is obtained.

...

Embodiment 1

[0041] The process of preparing bonded ferrite magnetic powder in this embodiment is as follows:

[0042] Weigh 1290g of iron red with a purity of 99.2%, 172g of strontium carbonate with a purity of 98%, 26g of barium carbonate with a purity of 99%, and 30 grams of strontium chloride, mix them uniformly with a strong mixer, and then pelletize to obtain green pellets;

[0043] The raw balls were sintered at 1220°C for 1 hour to obtain pre-sintered materials; the pre-sintered balls were roughly broken by a dry ball mill, then finely ground by a sand mill for 3 hours, and finely ground powder was obtained after drying;

[0044] The finely ground powder was annealed at 930° C. for 1 hour and dispersed to obtain bonded magnetic powder.

[0045] Compaction inspection: Weigh 20 grams of magnetic powder and 1.4 grams of paraffin wax and mix them evenly; then weigh 20 grams of the mixture and press it into a Φ25mm compact under a pressure of 7 MPa; use a BH instrument to test the magne...

Embodiment 2

[0052] The process of preparing bonded ferrite magnetic powder in this embodiment is as follows:

[0053] Weigh 1290g of iron red with a purity of 99.2%, 163g of strontium carbonate with a purity of 98%, 38.5g of barium carbonate with a purity of 99%, and 30 grams of strontium chloride, mix them uniformly with a strong mixer, and then pelletize to obtain green pellets ;

[0054] The raw balls were sintered at 1220°C for 1 hour to obtain pre-sintered materials; the pre-sintered balls were roughly broken by a dry ball mill, then finely ground by a sand mill for 3 hours, and finely ground powder was obtained after drying;

[0055] The finely ground powder was annealed at 930° C. for 1 hour and dispersed to obtain bonded magnetic powder.

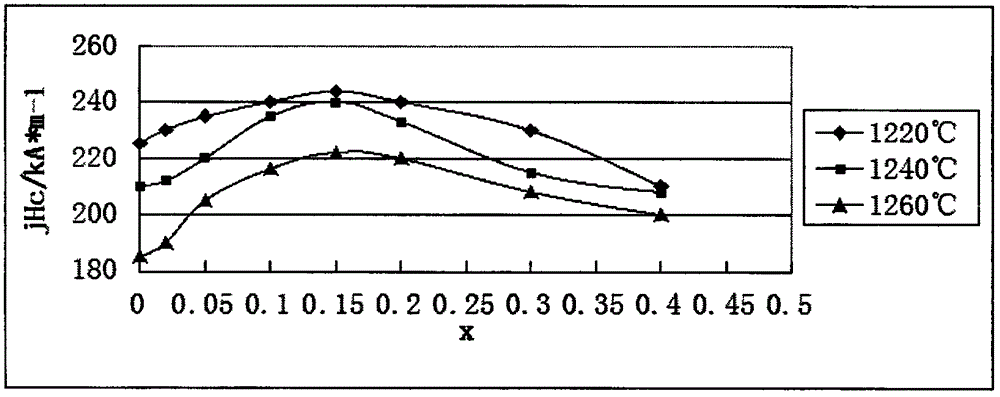

[0056] The green compact was tested with the same method as in Example 1, and the jHc detection value of the green compact in this embodiment was 244kA / m.

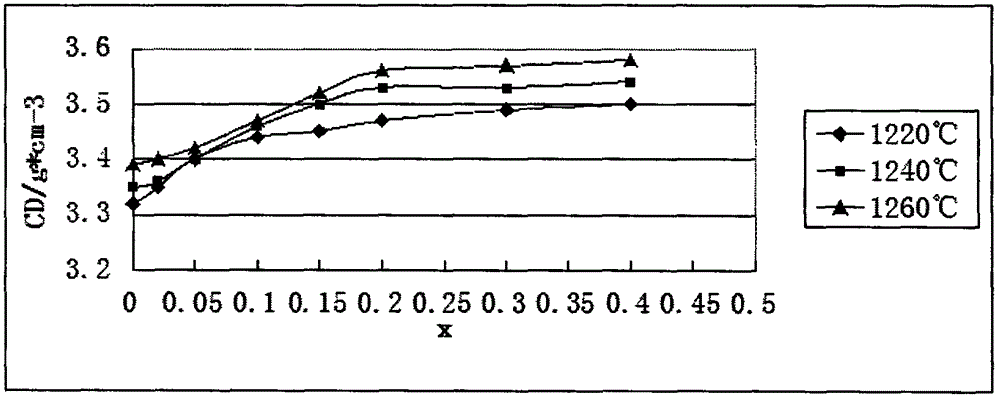

[0057] Carry out compression density (CD value) detection with the method for embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com