Nanoscale tio2/carbon airgel electrode with high {001} crystal plane exposure ratio and its preparation method and application

A carbon airgel and nano-scale technology, which is applied in separation methods, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of difficult recovery of catalysts, non-reusable conductivity, and restrictions on the application of photocatalytic oxidation technology. To achieve the effect of improving the performance of photocatalytic oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

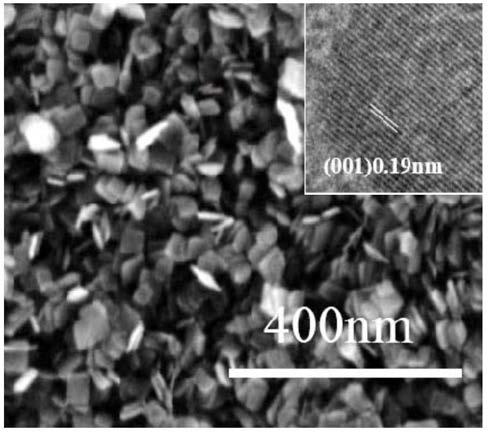

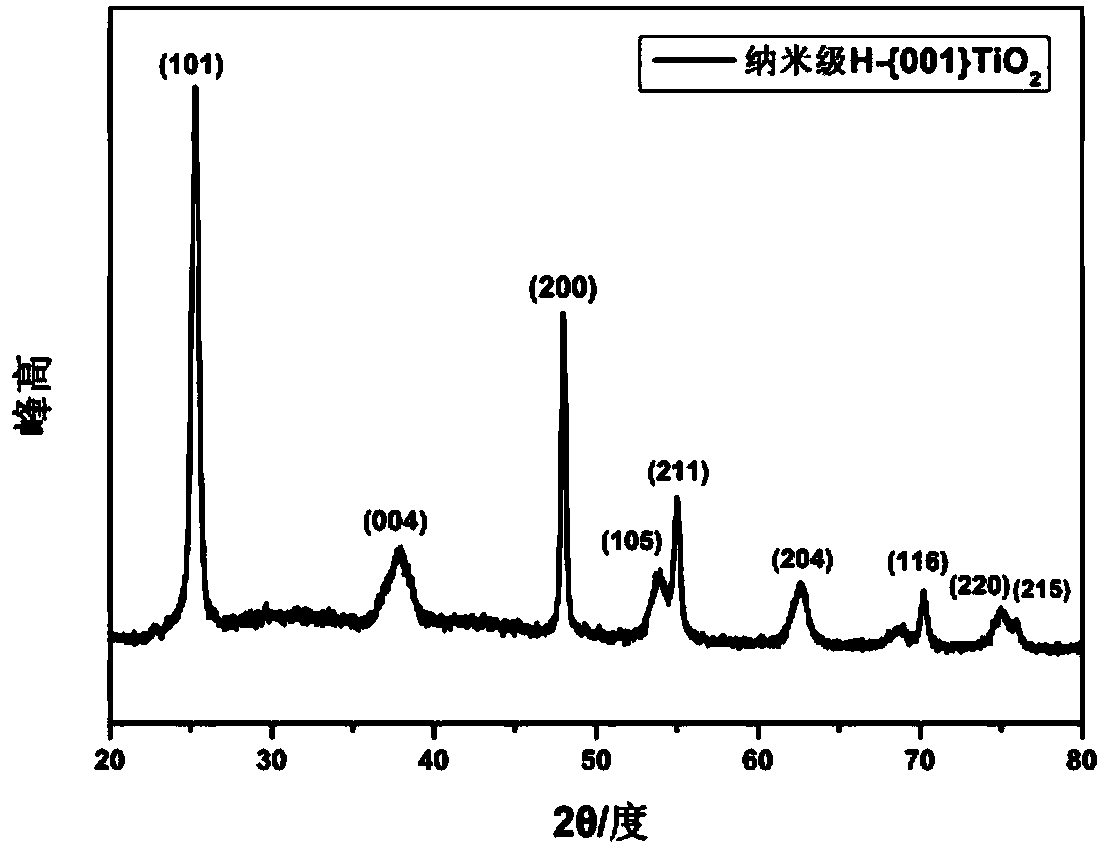

[0038] A Nanoscale H-{001}TiO 2 The preparation method of / CA electrode specifically comprises the following steps:

[0039] Slowly drop 0.6ml of hydrofluoric acid solution (40%, w / w%) into 5mL tetrabutyl titanate, stir with a magnetic stirrer during the dropwise addition, and transfer it to 30mL polytetrafluoroethylene Lined stainless steel reactor, placed in 180 ℃ oven for 24h. After the reaction, the reactor was cooled to room temperature, the product was centrifuged, and washed three times with deionized water and ethanol. After cleaning, the powder was dried at 80 °C for 12 h to obtain nano-sized TiO with a high proportion of {001} crystal faces. 2 . Using CA as cathode and titanium plate as anode, ultrasonically disperse 40mg nanoscale H-{001}TiO 2 10 mg of iodine is deposited in 50 mL of acetone for 30 min at a voltage of 15 V. After the deposition, the electrodes were taken out and dried at 60 °C for 12 h. Preparation of Nanoscale H-{001}TiO 2 / CA electrode.

[...

Embodiment 2

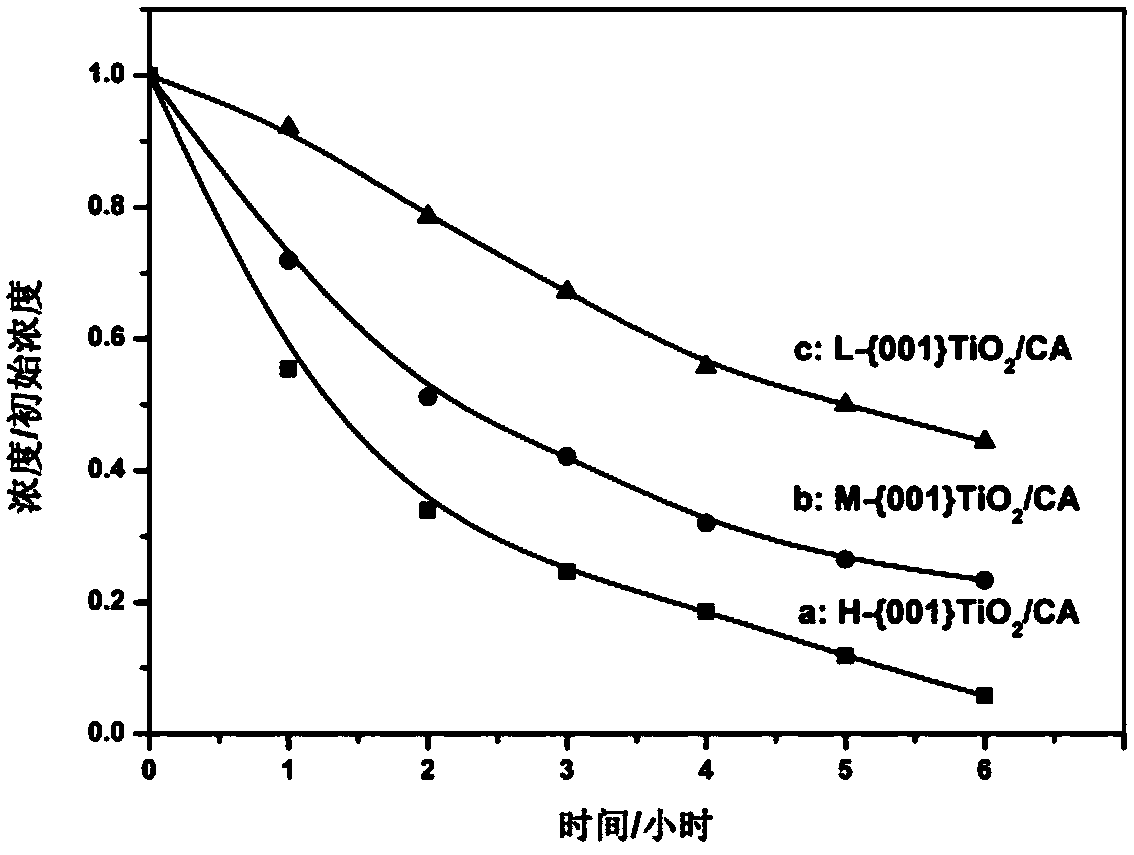

[0042] Nanoscale H-{001}TiO prepared by Example 1 2 / CA electrode photoelectrically degrades bisphenol A simulated wastewater efficiently, and the specific steps include the following:

[0043] The degradation experiment of bisphenol A was carried out in a circular electrochemical reaction cell, and a cup with circulating water was added to keep the constant temperature of the reaction system at 25°C. Using a three-electrode degradation system, nanoscale H-{001}TiO 2 The / CA electrode is the anode, the platinum sheet is the cathode, the distance between the cathode and the anode is 1cm, and the effective photoanode area is 1.5×2.5cm -2 . Use 0.1mol·L -1 Sodium sulfate deionized aqueous solution prepared bisphenol A into simulated wastewater with a concentration of 10mg / L, and the treatment volume was 100mL. Simulated sunlight as the light source, the light intensity is 100μW / cm 2 , apply a bias +0.9V (relative to the saturated calomel electrode), take samples at regular i...

Embodiment 3

[0046] This example is basically the same as Example 1, except that in this example, 0.6ml of hydrofluoric acid solution (40%, w / w%) is slowly dropped into 4mL of tetrabutyl titanate, and Stir with a magnetic stirrer, transfer to a 30mL polytetrafluoroethylene-lined stainless steel reaction kettle after the dropwise addition, and place in an oven at 200°C for 20h. After the reaction, the reactor was cooled to room temperature, the product was centrifuged, and washed three times with deionized water and ethanol. After cleaning, the powder was dried at 60 °C for 24 h to obtain nanoscale TiO with a high proportion of {001} crystal planes. 2 (nanoscale H-{001}TiO 2 ). Using CA as cathode and titanium plate as anode, ultrasonically disperse 50mg nanoscale H-{001}TiO 2 1. 15 mg of iodine element was deposited in 100 mL of acetone for 30 min at a voltage of 10 V. After the deposition, the electrodes were taken out and dried at 80 °C for 12 h. Preparation of Nanoscale H-{001}TiO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com