An organic fluorocarbon resin composite coating with antifouling and sterilization properties under visible light and its preparation method

A composite coating, organic fluorine technology, used in antifouling/underwater coatings, coatings, paints containing biocides, etc. problem, to achieve the effect of good inhibition, good photocatalytic activity, and high adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

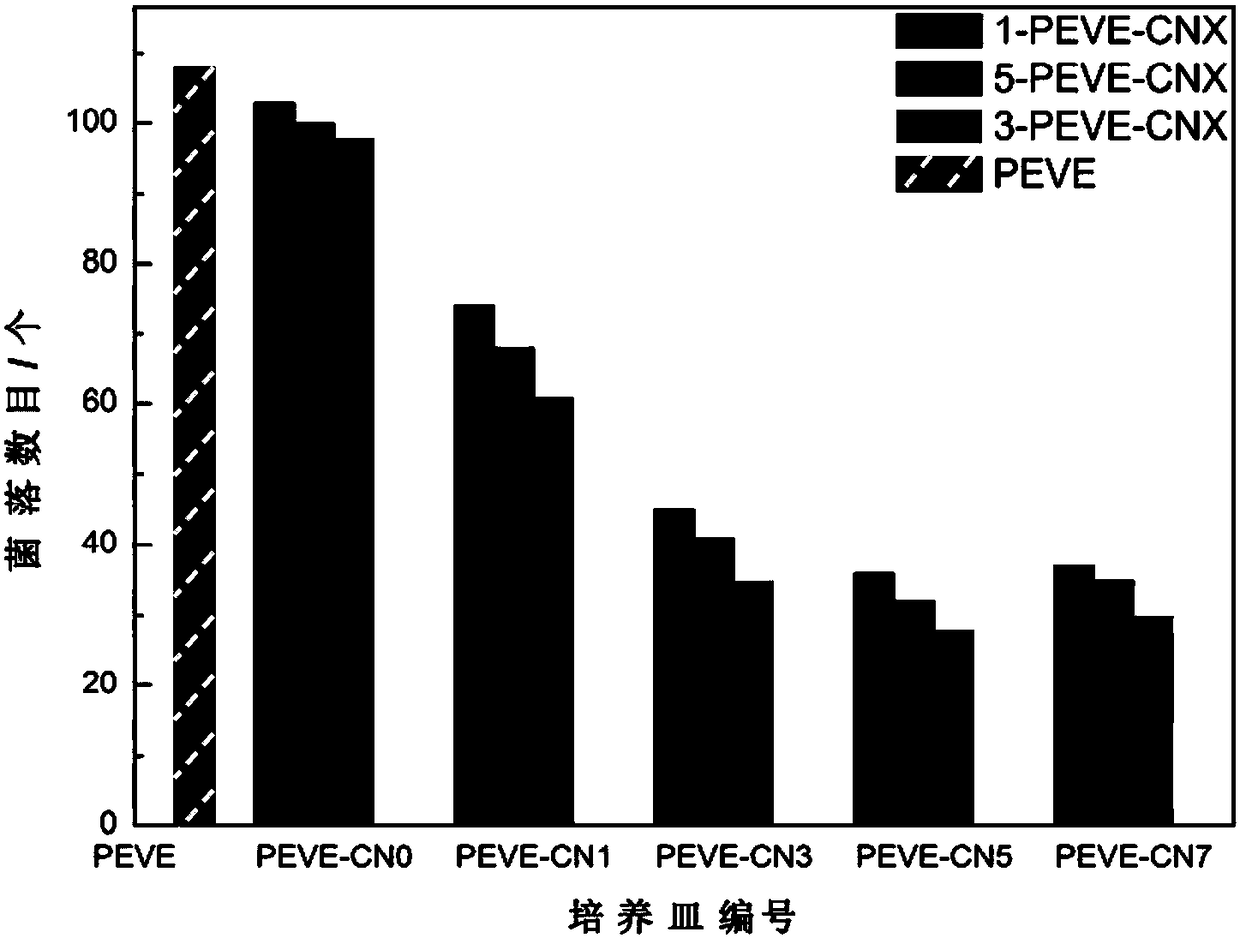

Examples

Embodiment 1

[0036] An organic fluorocarbon resin composite coating with antifouling and sterilization properties under visible light is characterized in that its preparation raw materials are made of the following components according to the weight percentage of the composite coating: 1% of nano titanium dioxide, 0.01% of graphite phase carbon nitride, poly Vinyl pyrrolidone 0.3%, organic fluorocarbon resin 73%, dispersant 10%, curing agent 15.69%.

[0037] The preparation method of the above-mentioned organic fluorocarbon resin composite coating for antifouling and sterilization performance, the preparation process comprises the following steps:

[0038] (1) Disperse 10 mg of graphite-phase carbon nitride into 100 mL of methanol, and then ultrasonicate the solution for 0.5-1 h to peel the graphite-phase carbon nitride into sheets to obtain a uniformly dispersed graphite-phase carbon nitride dispersion;

[0039] (2) Add 1000mg of titanium dioxide to the uniformly dispersed graphite phase ...

Embodiment 2

[0042]An organic fluorocarbon resin composite coating with antifouling and sterilization properties under visible light is characterized in that its preparation raw materials are made of the following components according to the weight percentage of the composite coating: 1% of nano titanium dioxide, 0.07% of graphite phase carbon nitride, poly Vinyl pyrrolidone 0.3%, organic fluorocarbon resin 73%, dispersant 10%, curing agent 15.63%.

[0043] The preparation method of the above-mentioned organic fluorocarbon resin composite coating for antifouling and sterilization performance, the preparation process comprises the following steps:

[0044] (1) Disperse 70 mg of graphite-phase carbon nitride into 100 mL of methanol, and then ultrasonicate the solution for 0.5 to 1 hour to peel the graphite-phase carbon nitride into sheets to obtain a uniformly dispersed graphite-phase carbon nitride dispersion;

[0045] (2) Add 1000mg of titanium dioxide to the uniformly dispersed graphite p...

Embodiment 3

[0048] An organic fluorocarbon resin composite coating with antifouling and sterilization properties under visible light is characterized in that its preparation raw materials are made of the following components according to the weight percentage of the composite coating: 1% of nano titanium dioxide, 0.03% of graphite phase carbon nitride, poly Vinyl pyrrolidone 0.3%, organic fluorocarbon resin 73%, dispersant 10%, curing agent 15.67%.

[0049] The preparation method of the above-mentioned organic fluorocarbon resin composite coating for antifouling and sterilization performance, the preparation process comprises the following steps:

[0050] (1) Disperse 30 mg of graphite-phase carbon nitride into 100 mL of methanol, and then ultrasonicate the solution for 0.5 to 1 hour to peel the graphite-phase carbon nitride into sheets to obtain a uniformly dispersed graphite-phase carbon nitride dispersion;

[0051] (2) Add 1000mg of titanium dioxide to the uniformly dispersed graphite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com