Needle of jetting nozzle for water jet loom

A technology of water jet looms and nozzles, which is applied in the direction of looms, textiles, and jetting devices. It can solve the problems of fabric quality degradation, broken weft insertion, increase of jet water volume and jet water pressure, etc., and achieve the effect of diffusion and clustering. The effect of drop minimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

[0038] Prior to the description of the present invention, a brief description will be given or omitted about the technical configuration commonly used in nozzles for water jet looms in general.

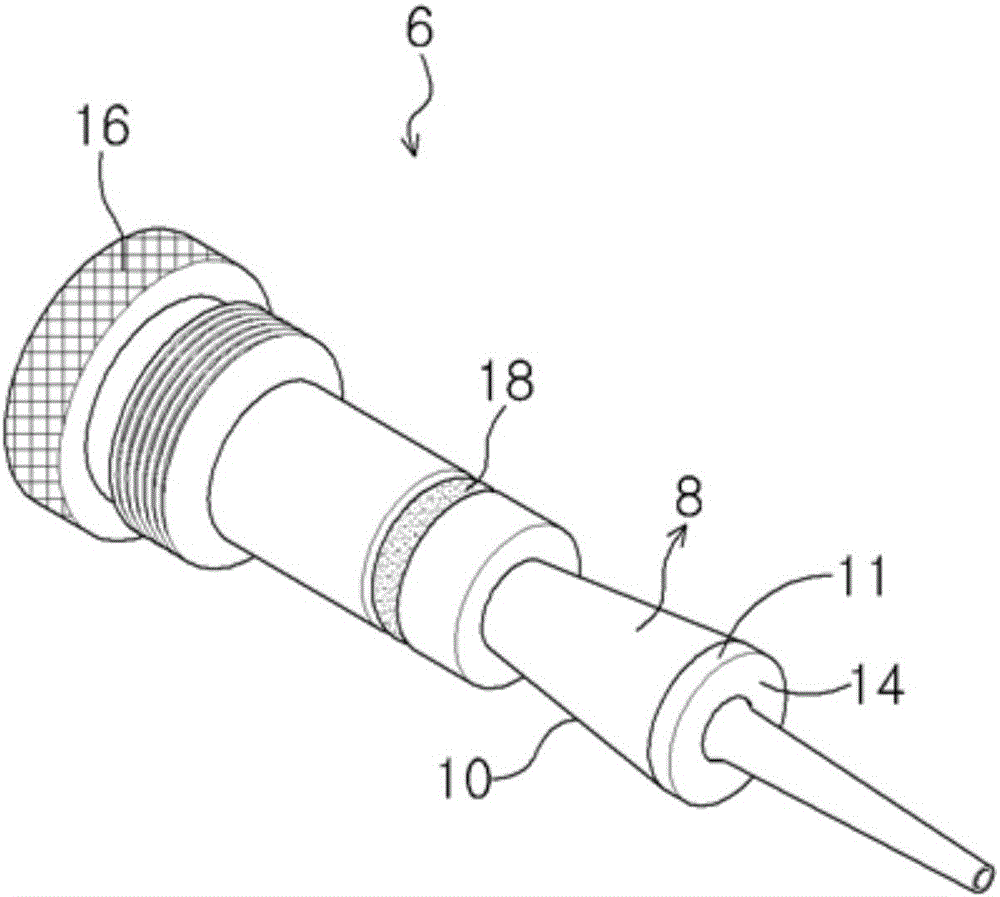

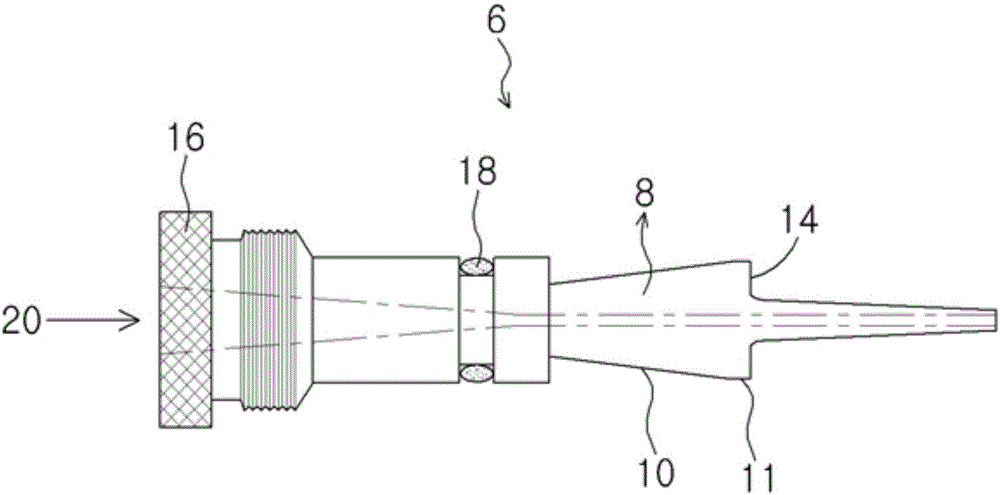

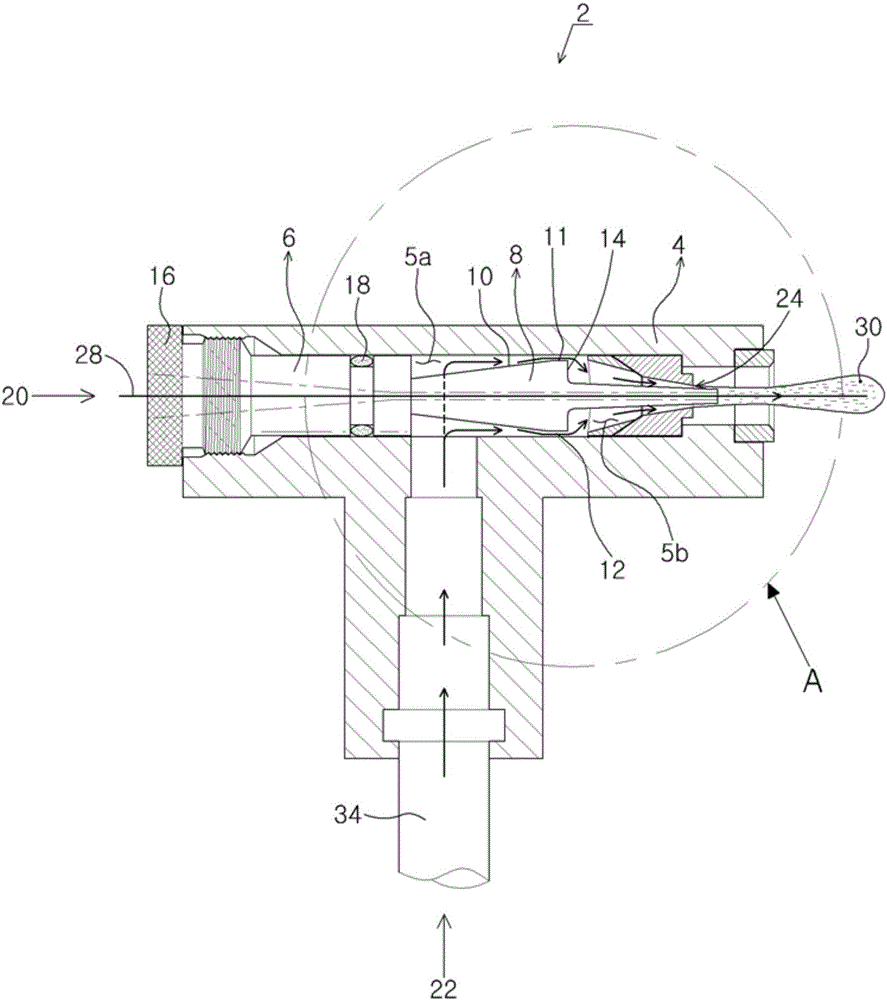

[0039] In the present invention, by improving the shape of the spray needle 6 of the nozzle 2 for a water-jet loom, the diffusion of sprayed water and the decrease in convergence are minimized.

[0040] Figure 6 and Figure 7 It is a configuration diagram showing a nozzle of a conventional water jet loom nozzle.

[0041] Such as Figure 6 As shown, the structure of the spray needle of the existing nozzle for water jet loom is as follows, that is, the water flowing into the spray needle from the side through the water supply pipe bends vertically inside the nozzle, and then sprays through the front of the nozzle, that is, the discharge port.

[0042] Thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com