High-performance bulldozing device

A high-performance, high-temperature technology, used in machines that use waste heat, how machines operate, and climate change adaptation. Loss, ease of cleaning, savings in investment and space occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

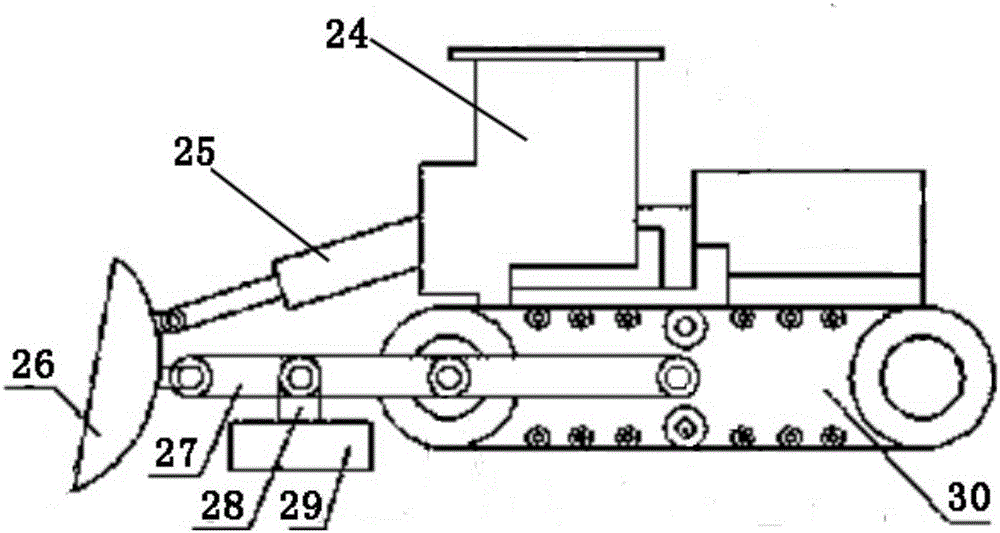

[0021] Such as figure 1 A high-performance bulldozing device shown includes a cab 24, a hydraulic rod 25, a bulldozer bucket 26, a beam 27, a column 28, a vibrating plate 29, a drive crawler belt 30 and an engine energy recovery device, and the bulldozer bucket 26 The hydraulic rod 25 is connected to the cab 24, and the beam 27 is located below the hydraulic rod 25, and one end thereof is hinged to the bulldozing bucket 26; A vibrating motor (not shown) is arranged in the plate 29 ; the drive track 30 is driven by the engine 2 .

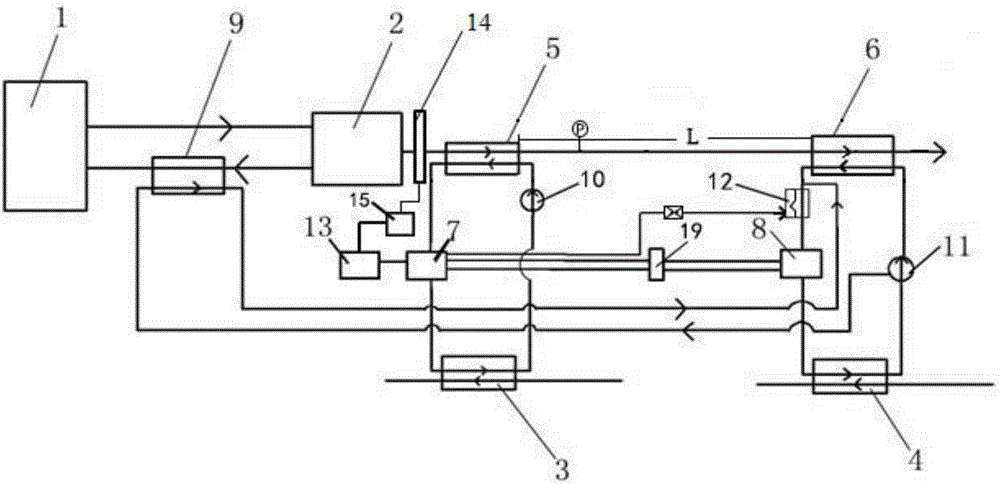

[0022] Such as figure 2 As shown, the engine energy recovery device is used to recover the energy of the exhaust gas of the engine 2, which includes a radiator 1, an engine 2, a return water evaporator 9, a high-temperature heat exchange circuit, a low-temperature heat exchange circuit, a battery pack 13, an inverter and a frequency conversion Device 15 and back pressure regulating blower 14. The radiator 1 is connected with the engine 2, and the...

Embodiment 2

[0032] Such as figure 1 A high-performance bulldozing device shown includes a cab 24, a hydraulic rod 25, a bulldozer bucket 26, a beam 27, a column 28, a vibrating plate 29, a drive crawler belt 30 and an engine energy recovery device, and the bulldozer bucket 26 The hydraulic rod 25 is connected to the cab 24, and the beam 27 is located below the hydraulic rod 25, and one end thereof is hinged to the bulldozing bucket 26; A vibrating motor (not shown) is arranged in the plate 29 ; the drive track 30 is driven by the engine 2 .

[0033] Such as figure 2As shown, the engine energy recovery device is used to recover the energy of the engine exhaust, which includes a radiator 1, an engine 2, a return water evaporator 9, a high-temperature heat exchange circuit, a low-temperature heat exchange circuit, a battery pack 13, an inverter and a frequency converter 15 and back pressure regulating fan 14. The radiator 1 is connected with the engine 2, and the radiator 1 transfers the...

Embodiment 3

[0043] Such as figure 1A high-performance bulldozing device shown includes a cab 24, a hydraulic rod 25, a bulldozer bucket 26, a beam 27, a column 28, a vibrating plate 29, a drive crawler belt 30 and an engine energy recovery device, and the bulldozer bucket 26 The hydraulic rod 25 is connected to the cab 24, and the beam 27 is located below the hydraulic rod 25, and one end thereof is hinged to the bulldozing bucket 26; A vibrating motor (not shown) is arranged in the plate 29 ; the drive track 30 is driven by the engine 2 .

[0044] Such as figure 2 As shown, the engine energy recovery device is used to recover the energy of the engine exhaust, which includes a radiator 1, an engine 2, a return water evaporator 9, a high-temperature heat exchange circuit, a low-temperature heat exchange circuit, a battery pack 13, an inverter and a frequency converter 15 and back pressure regulating fan 14. The radiator 1 is connected with the engine 2, and the radiator 1 transfers the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com