Guide rail type novel wall brick and construction method thereof

A construction method and wall brick technology, applied in the field of building materials, can solve the problems of low efficiency, high cost, cumbersome procedures for bricklaying workers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

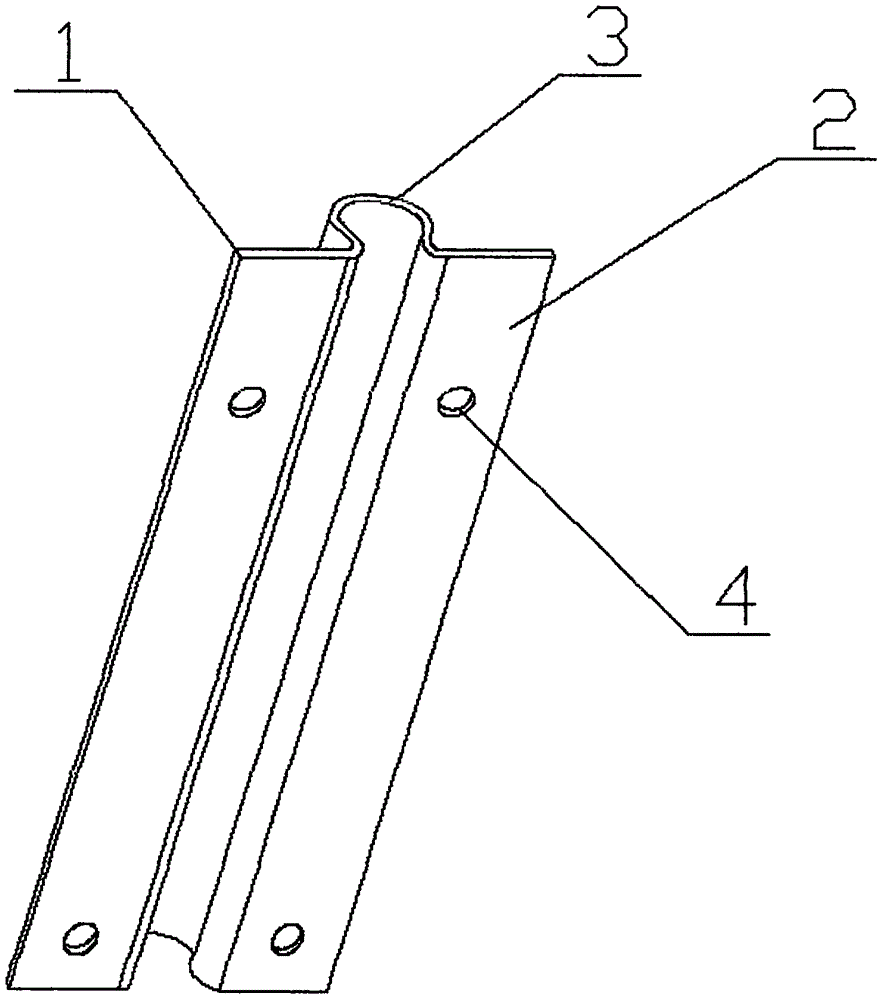

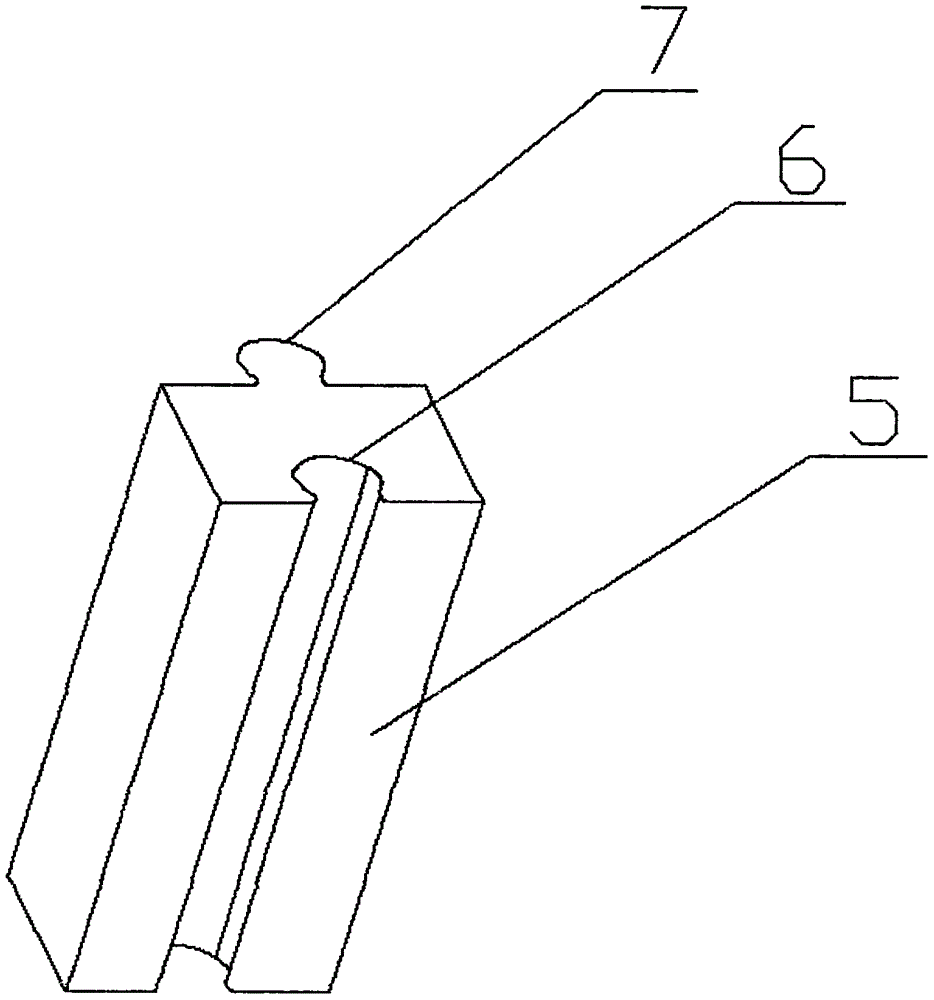

[0025] refer to figure 1 figure 2 , image 3 , Figure 4 , a new rail-type wall brick, characterized in that its structure includes: fixed iron plate 1, side plate 2, circular convex groove 3, round hole 4, building block 5, building block circular groove 6, building block convex and concave Slot 7; the fixed iron plate 1 is made up of a side plate 2 and a circular convex groove 3, the circular hole 4 is arranged on the side plate 2, the building block 5 is a cuboid structure, and building blocks are arranged on the building block 5 Block circular groove 6 and building block convex groove 7, described fixed iron plate 1 is connected in circular convex groove 3 both sides by left and right two side plates 2, and described circular hole 4 has two to offer on side plate 2.

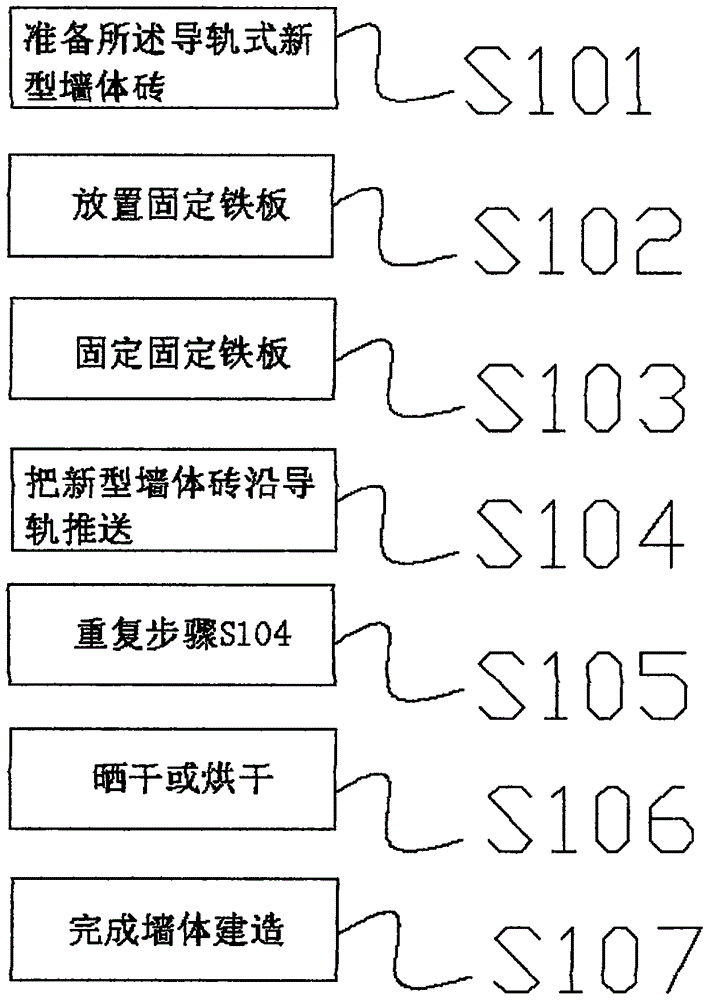

[0026] A construction method for guide rail type new wall bricks, characterized in that: the construction method includes the following steps:

[0027] Step S101, preparing the guide rail type new wall b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com