Polar region drilling machine

A technology for drilling rigs and drill pipe racks, which is applied to drilling equipment, ice drilling, and earth-moving drilling, etc., can solve problems such as the inability of drilling rigs to meet normal operation requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

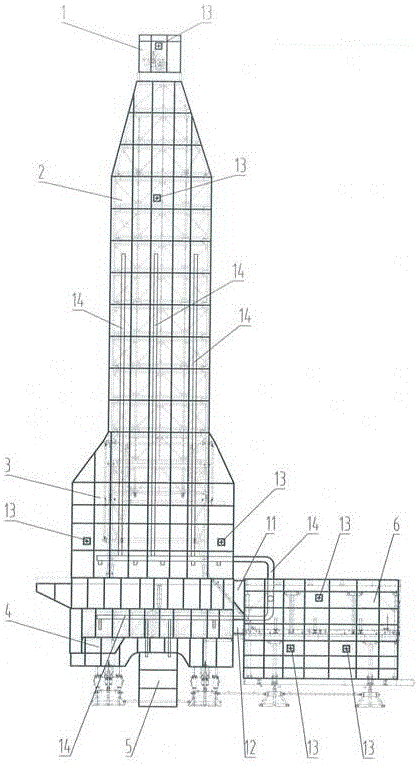

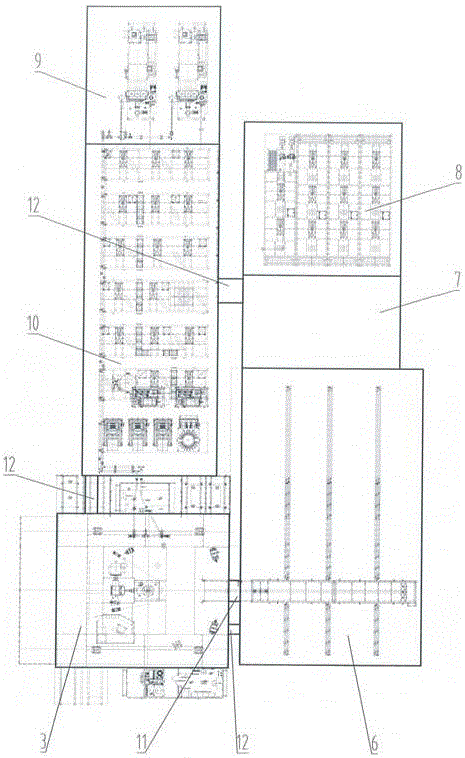

[0032] Below in conjunction with accompanying drawing, the present invention is described in detail.

[0033] Such as figure 1 , figure 2As shown, the polar drilling rig has a crane insulation shed 1, a derrick insulation shed 2, a drilling floor insulation shed 3, a base insulation shed 4, a wellhead insulation shed 5, a drill pipe rack insulation shed 6, a mud material insulation shed 7, and a storage tank insulation Shed 8, mud pump insulation shed 9, solid control insulation shed 10, wherein the crane is located in the crown crane insulation shed 1, the derrick is located in the derrick insulation shed 2 and the drilling floor insulation shed 3, the base is located in the base insulation shed 4, and the wellhead is located in In the wellhead insulation shed 5, the drill rod rack is located in the drill rod rack insulation shed 6, the mud material room is located in the mud material insulation shed 7, the reserve tank is located in the reserve tank insulation shed 8, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com