Visual scanning and distance measuring method for coal quantity passing belt conveyer

A technology of belt conveyors and detection methods, applied in the direction of measuring devices, instruments, and optical devices, can solve the problems of low measurement accuracy and large constraints, and achieve the effects of high measurement accuracy, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

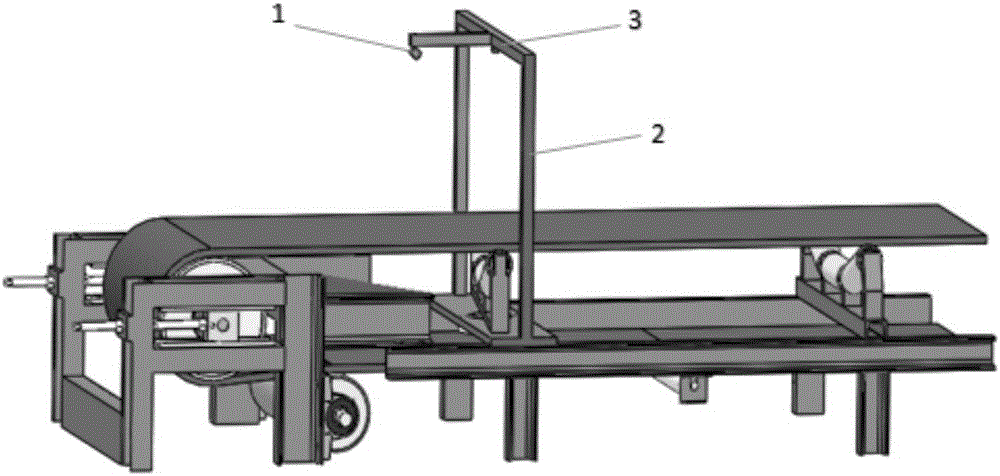

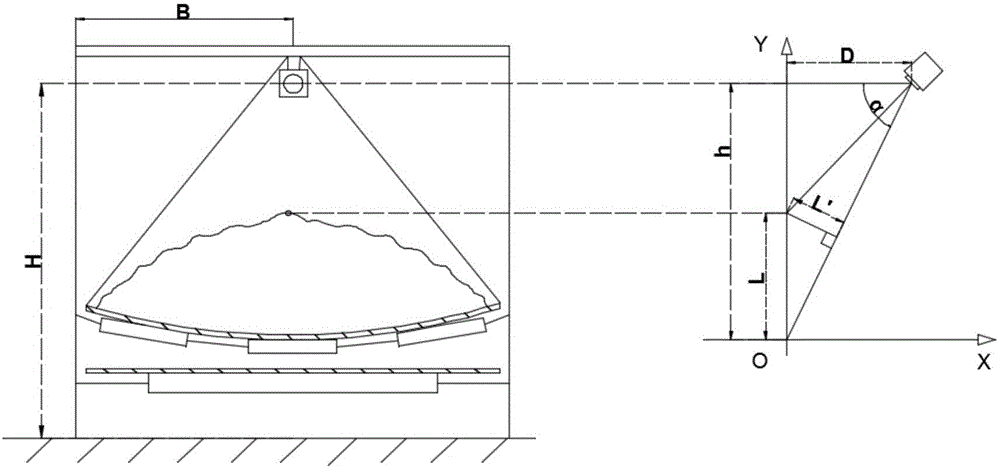

[0032] figure 1 It is a schematic diagram showing the structure of a distance measuring device with a detection surface, a line light source and a CCD smart camera according to an embodiment of the invention. When the conveyor belt width of the belt conveyor is 2m and the conveyor belt running speed is 5m / s, its main technical indicators are:

[0033] Power supply: ~220V 10% 50HZ

[0034] Signal transmission distance: Infrared CCD camera output signal Optical fiber transmission: 1Km

[0035] Working temperature: 30°C

[0036] The coincidence between the detected volume and the actual volume: 98%

[0037] Image detection resolution: 1.5mm

[0038] Imaging frame frequency: 30 frames / s

[0039] Conveyor belt width: 2m

[0040] Detect the running speed of the conveyor belt: 5m / s.

[0041]The working process of the above-mentioned method for visually scanning and measuring the amount of coal conveyed by a belt conveyor is as follows: install a line light source on the center...

Embodiment approach 2

[0048] When the width of the conveyor belt of the belt conveyor is less than 1.5m and the running speed of the conveyor belt is lower than 5m / s, the main technical indicators of the device are:

[0049] Power supply: ~220V±10%50HZ

[0050] Signal transmission distance: Infrared CCD camera output signal Optical fiber transmission: 1Km

[0051] Working temperature: 30°C

[0052] The coincidence between the detected volume and the actual volume: 98%

[0053] Image detection resolution: 1.5mm

[0054] Imaging frame frequency: 30 frames / s

[0055] Conveyor belt width: 1.2m

[0056] Detect the running speed of the conveyor belt: 3.5m / s.

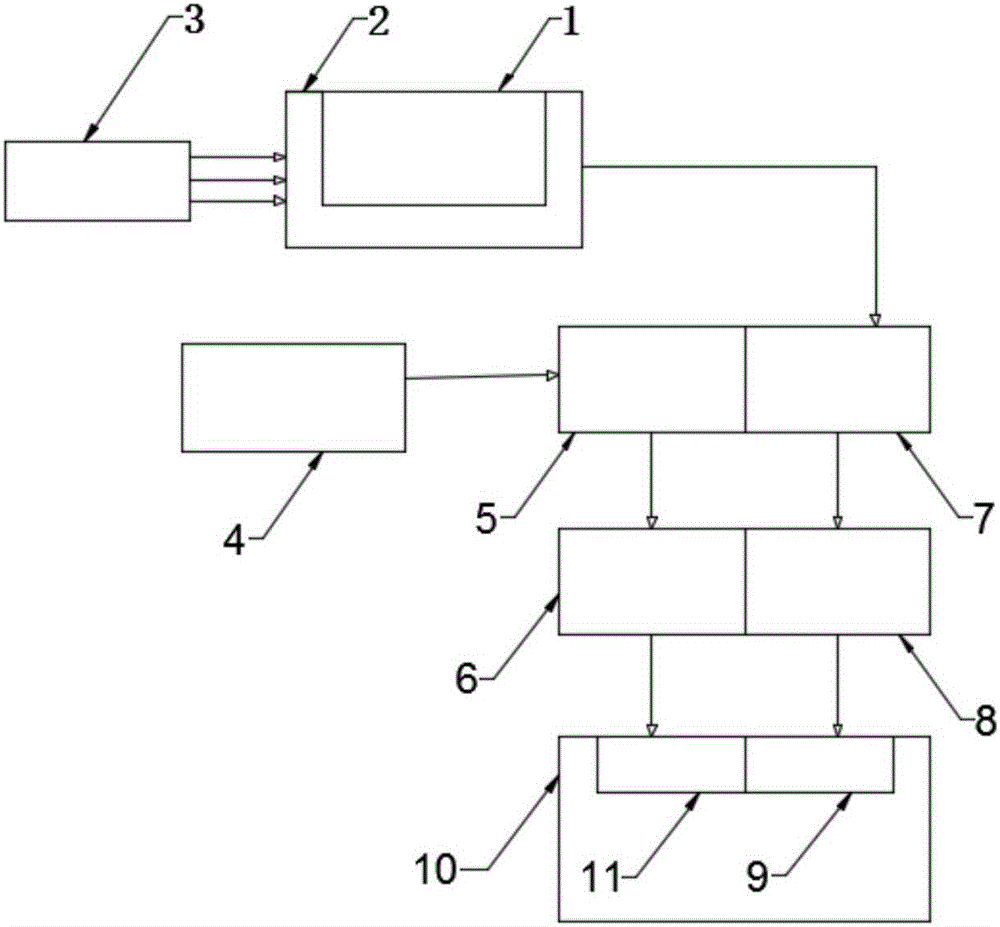

[0057] The speed sensor detects the running speed of the conveyor belt through the TCF-142RS485 / optical fiber module 5 using optical fiber transmission, and then through the TCF-142 optical fiber / RS232 module 6 through the RS-232 interface 11 to the host computer. Others are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com