Measuring method for tooth groove torque of permanent magnet motor

A technology of permanent magnet motor and cogging torque, which is applied in force/torque/power measuring instruments, measuring devices, instruments, etc., which can solve the problems of high instrument cost, complicated measurement methods, and single test function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

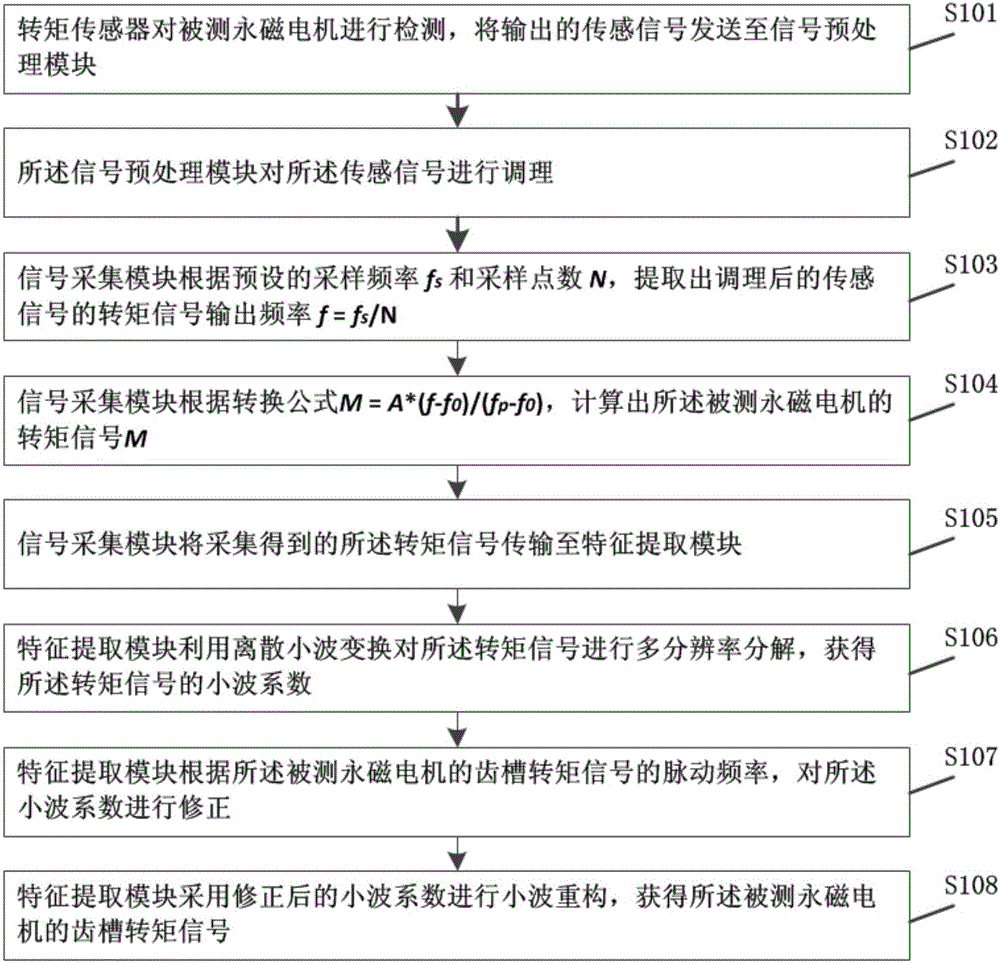

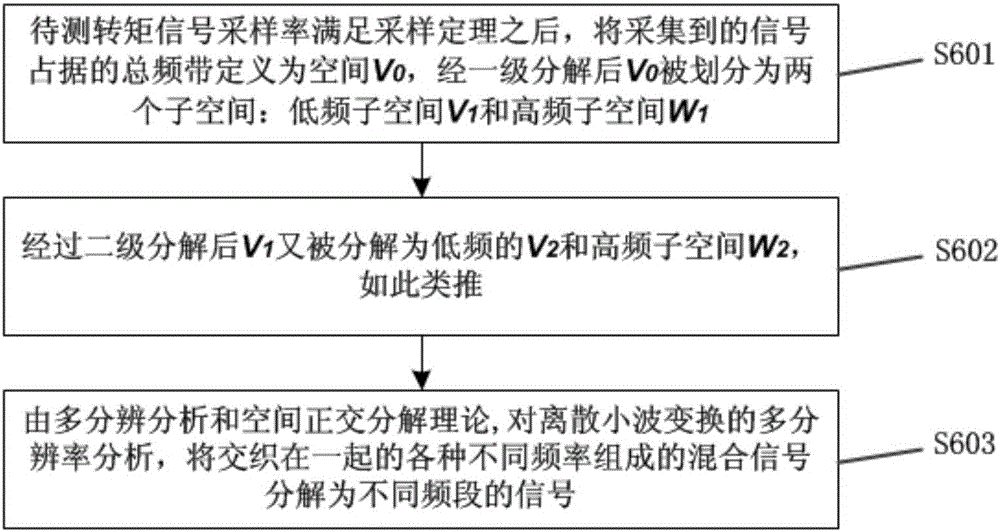

[0056] see figure 1 , is a schematic flowchart of an embodiment of a method for measuring cogging torque of a permanent magnet motor provided by the present invention.

[0057] In this embodiment, by utilizing a measuring device composed of a torque sensor, a signal preprocessing module, a signal acquisition module, a feature extraction module, and an industrial control computer, the method for measuring the cogging torque of a permanent magnet motor includes the following steps S101~step S108:

[0058] Step S101: The torque sensor detects the torque of the permanent magnet motor under test, and sends the sensing signal output by the torque sensor to the signal preprocessing module.

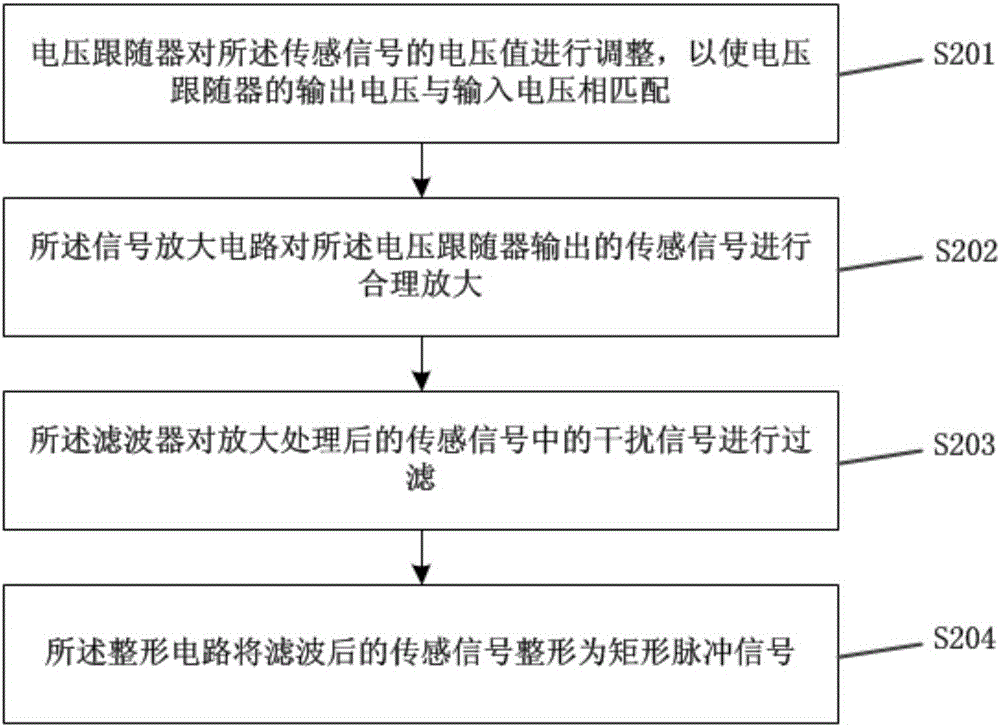

[0059] Step S102: the signal preprocessing module conditions the sensing signal. Specifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com