F valve stationary superheat degree automatic testing device and testing method

An automatic test device and superheat technology, which are used in measuring devices, testing of mechanical parts, testing of fluid tightness, etc., can solve problems such as difficulty in meeting testing requirements, and achieve the effect of high degree of automation and optimized adjustment accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawings and embodiments.

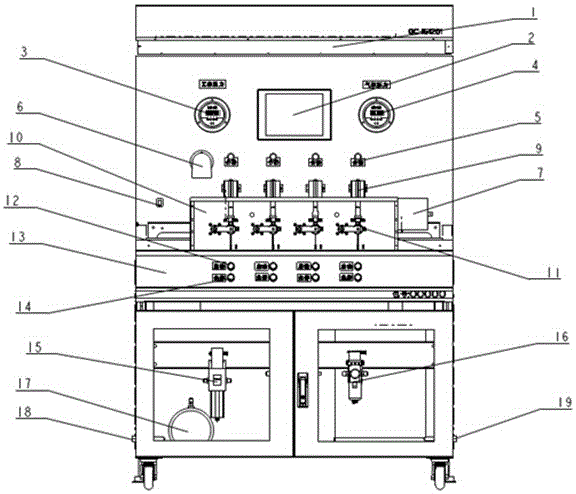

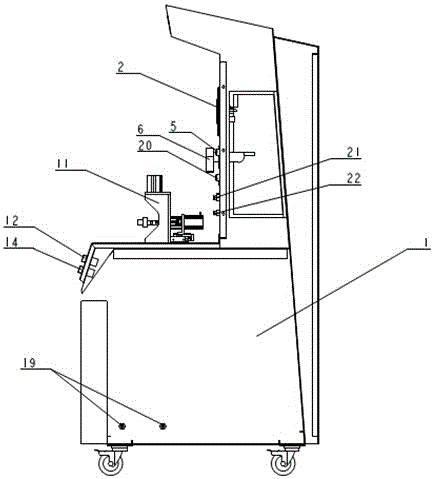

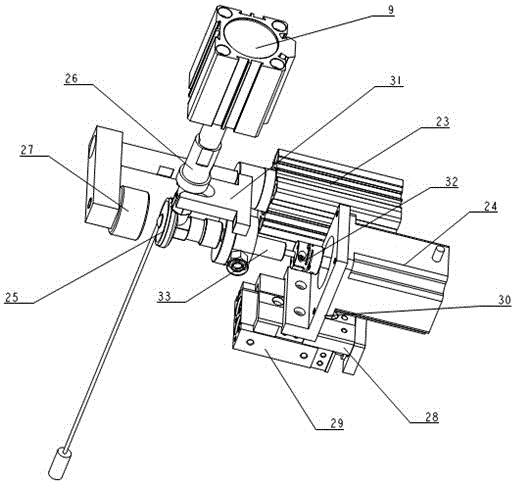

[0023] As shown in Figure 1 and Figure 2, there are 4 test fixtures installed in the middle of the front end of the vertical operating platform 1

[0024] 11. There is a constant temperature tank controller 7 on the right side of the test tool 11, a power switch 8 on the left side of the test tool 11, a display screen 2 directly above the test tool 11, and 4 sets of qualified indicator lights 5 and unqualified indicators on the lower side of the display screen 2 Light 20, barcode reader 6 is arranged on the left side of qualified indicator light 5, there are 4 groups of air inlet pipe interface 21 and air outlet pipe interface 22 under qualified indicator light 5, working pressure gauge 3 is arranged on the left side of display screen 2, and cylinder is arranged on the right side of display screen 2 Pressure gauge 4, there are 4 sets of start keys 12 and em...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap