Portable operation platform for optical fiber fusion welding

A technology of optical fiber fusion splicing and working platform, which is applied in the direction of optics, light guides, optical components, etc., can solve the problems of inconvenient carrying, inconvenient operator, complicated installation procedures, etc., to ensure the stability of optical fiber splicing, improve operating comfort, and operate The effect of increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

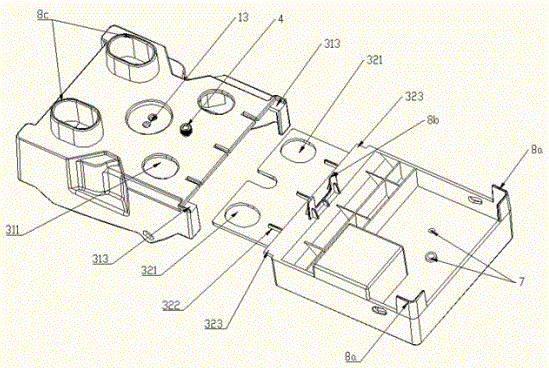

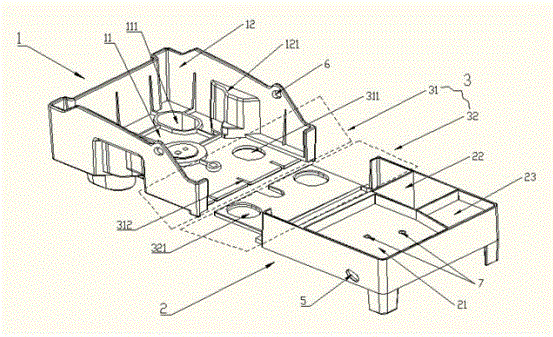

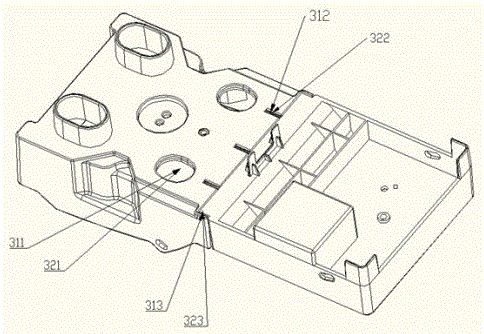

[0030] refer to figure 1 and figure 2 , the present invention provides a portable optical fiber fusion splicing platform, including an optical fiber fusion splicing platform 1 and an optical fiber cutting platform 2, wherein the optical fiber fusion splicing platform 1 is used to accommodate an optical fiber fusion splicing machine, and the optical fiber fusion splicing platform includes a fixed part 11 of the optical fiber fusion splicing machine And the optical fiber fusion splicer limit part 12, the optical fiber fusion splicer fixed part 11 is provided with the optical fiber fusion splicer placement hole 111 and the optical fiber fusion splicer locking hole 13, the size of the optical fiber fusion splicer placement hole 111 and the foot size of the optical fiber fusion splicer Adaptation, the locking hole 13 of the optical fiber fusion splicer corresponds to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com