Motor closed loop control system based on precise signal feedback

A signal feedback and motor closed-loop technology, applied in the direction of feedback control, control system, motor generator control, etc., can solve problems such as inability to accurately control the motor and affect the positioning accuracy of the workbench, so as to improve displacement accuracy and positioning The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

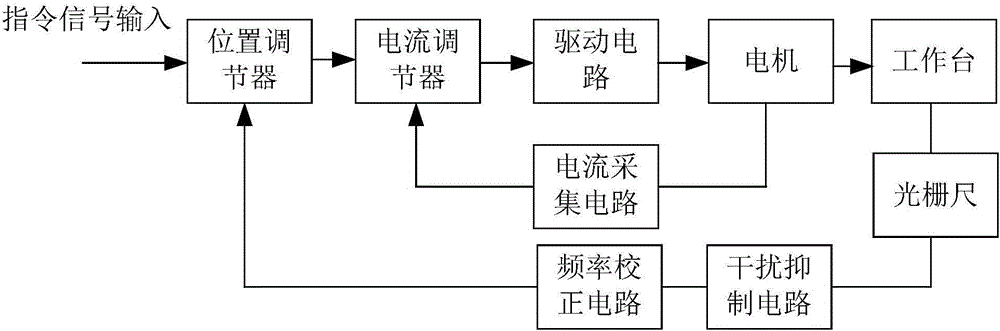

[0024] Such as figure 1 As shown, the motor closed-loop control system based on accurate signal feedback of the present invention is mainly composed of a position regulator, a current regulator connected with the position regulator, a drive circuit connected with the current regulator, and a motor connected with the drive circuit , the workbench connected with the motor, the grating ruler connected with the workbench, the interference suppression circuit connected with the grating ruler, the frequency correction circuit connected in series between the interference suppression circuit and the position regulator, and the frequency correction circuit connected in series between the motor It is composed of the current acquisition circuit between the current regulator and the current regulator.

[0025] Wherein, the workbench is the control object of the motor, which may be the workbench of the machine tool. The motor is used to drive the workbench to move, and it is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com