Modularized construction method of mine development system model

A system model and construction method technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve problems such as poor intuition, no solution, and complex development of system space, achieving strong adaptability, easy disassembly, Strong intuitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

[0038] A modular construction method of mine development system model includes the following steps:

[0039] Step 1: Carry out modular classification of mine development system. The classified mine development system includes shaft module, tunnel module, shaft connection module and chamber module;

[0040] Step 2: Reclassify the shaft module, roadway module, shaft connection module and chamber module. The classification results are as follows:

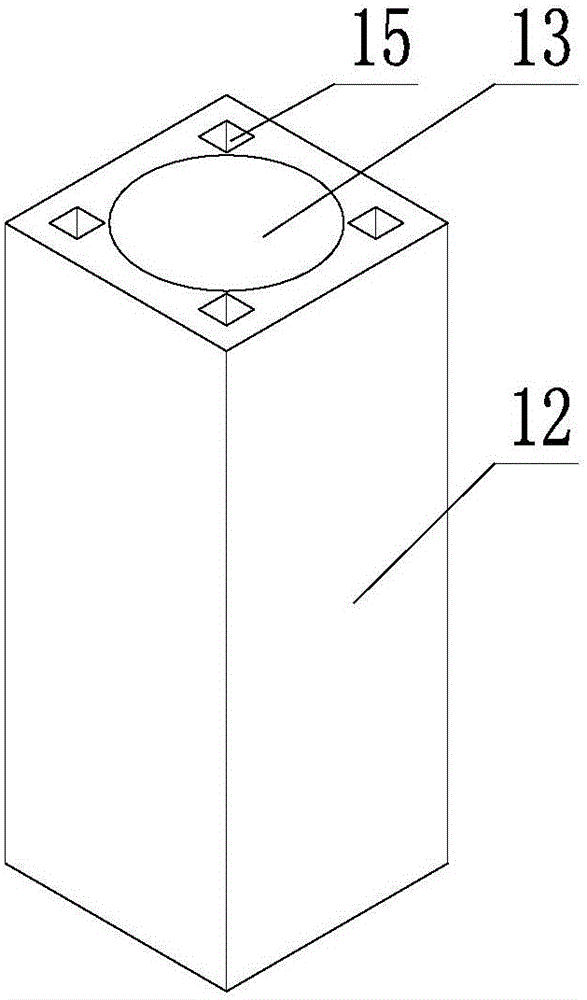

[0041] ① The shaft module includes several shaft unit bodies 1;

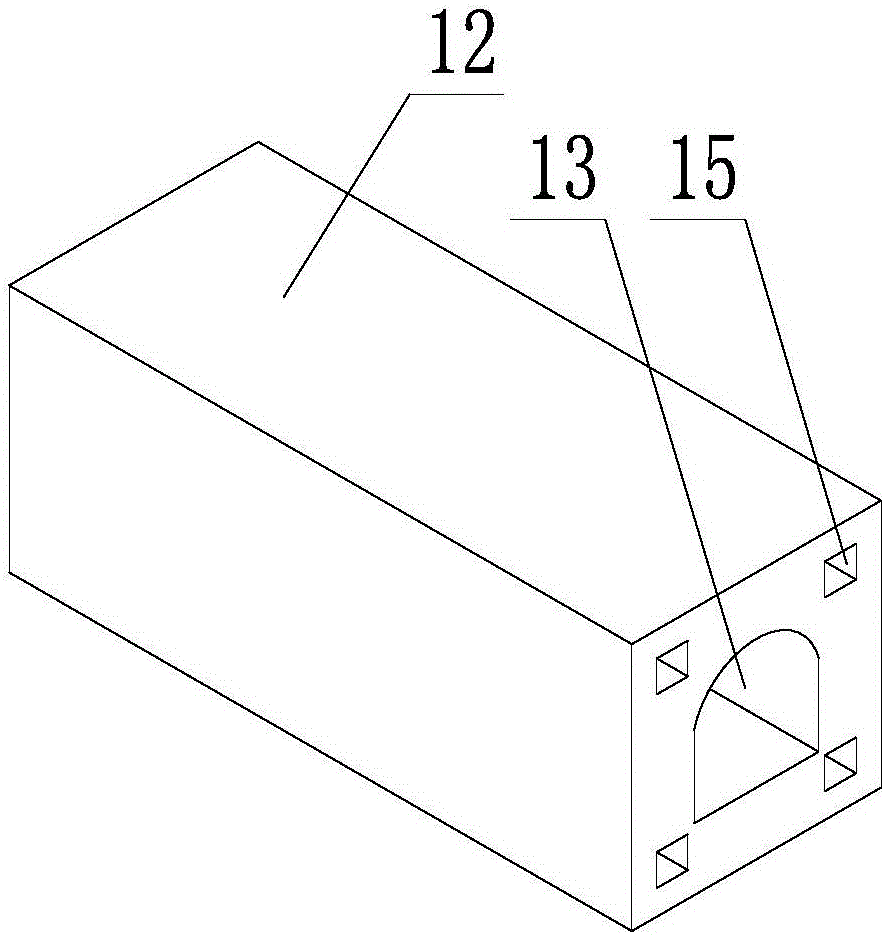

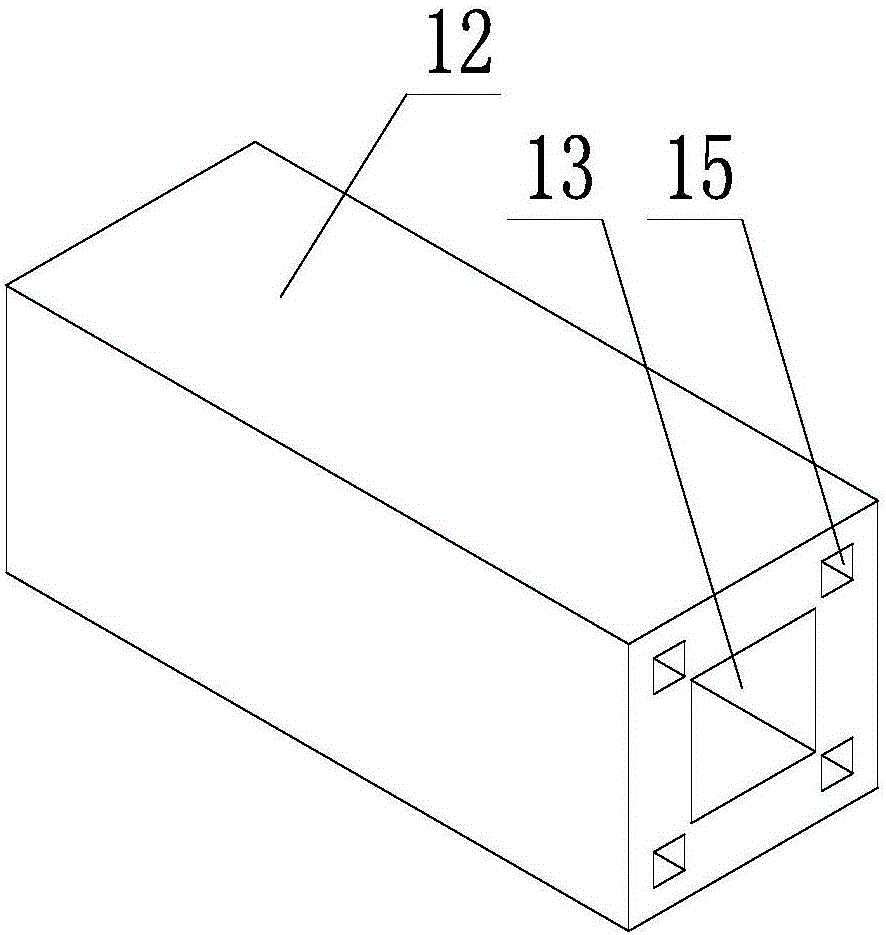

[0042] ②The roadway module includes several arched roadway unit bodies 2 and several square roadway unit bodies 3;

[0043] ③The roadway connection module includes several double-sided horse head door unit bodies 4, several single-sided horse head door unit bodies 5, several single turning unit bodies 6, several combined turning unit bodies 7, and severa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com