A nanowire device based on bridge growth and its preparation method

A technology of nanowires and devices, which is applied in the field of nanowire devices based on bridge growth and its preparation, and the preparation of nanowire electronic devices and optoelectronic devices. It can solve the problems of increasing process complexity, deteriorating electrical contact characteristics, and complex preparation processes. Achieve the effects of improving electrical contact characteristics, eliminating pollution and damage, and improving conductive characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the nanowire device of the present invention can complete the preparation of the nanowire device during the growth process of the nanowire 7, omits the traditional steps of stripping, transferring and arranging the nanowire 7, and eliminates the pollution and pollution on the surface of the nanowire 7 damage, and improve the electrical contact characteristics between the metal electrode and the nanowire 7.

[0036] The conductive thin film 3 provided on the side wall 2 of the groove structure in this embodiment is not only the substrate for the growth of the nanowire 7, but also the electrode of the nanowire device. Since the electron density in the conductive film 3 (such as a metal film) is very high, good electrical contact can be formed between the conductive film 3 and the nanowire 7 no matter whether the nanowire 7 is n-type or p-type. In addition, compared with the traditional method of plating electrodes on the surface of the nanowire 7...

Embodiment 1

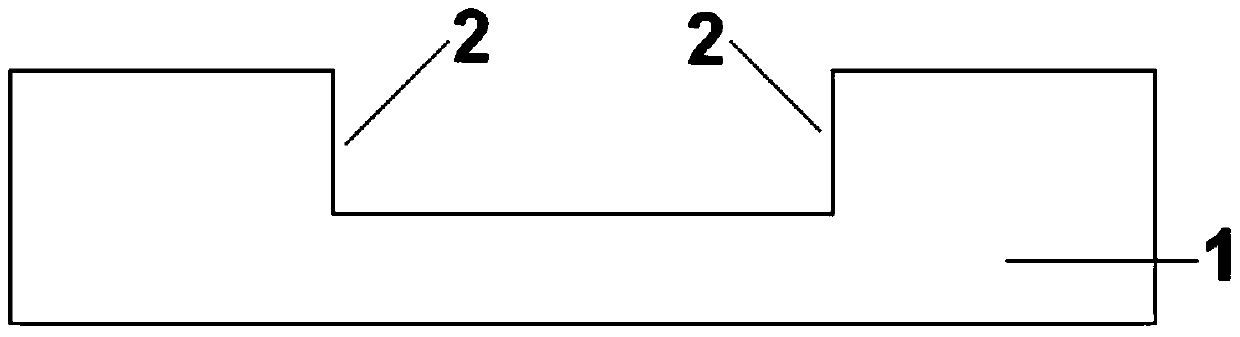

[0040] First, on the surface of the quartz glass substrate, a groove structure (such as figure 1 ).

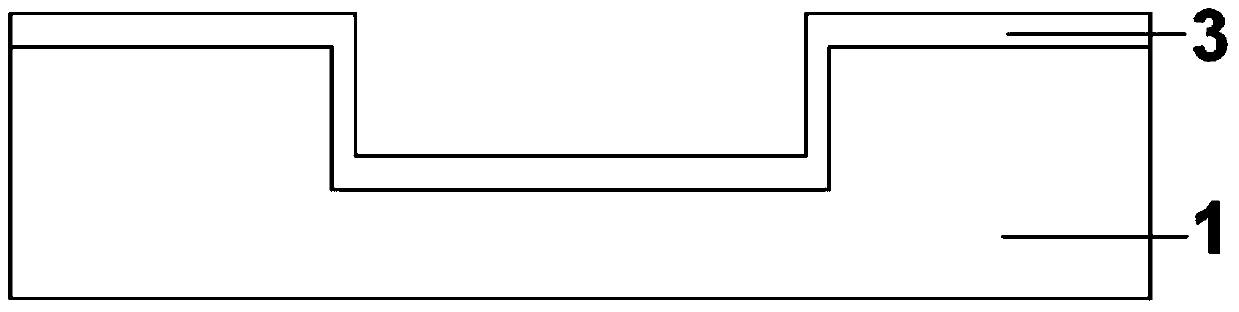

[0041] Secondly, titanium conductive film 3 is plated on the substrate surface (such as figure 2 ), titanium conductive film has good conductivity.

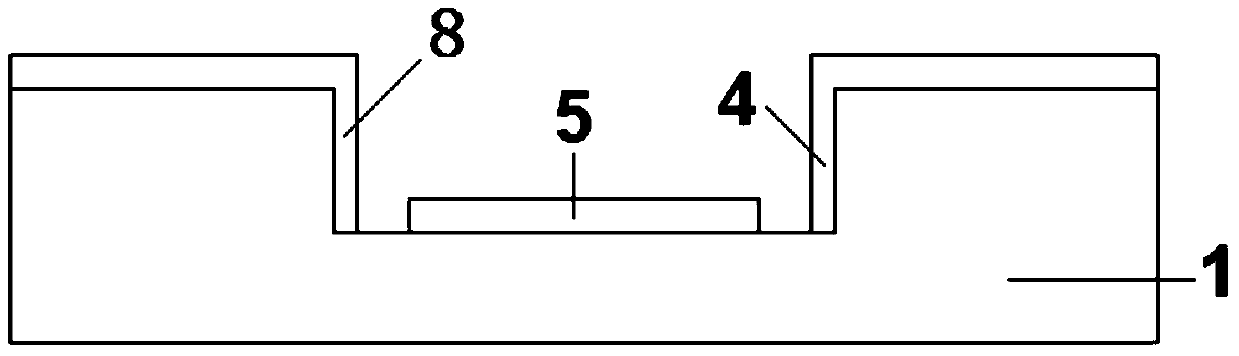

[0042] Then, utilizing an etching process, the conductive film 3 is divided, so that the source electrode 4 and the drain electrode 8 of the side wall 2 are insulated from each other, and the source electrode 4, the drain electrode 8 and the gate electrode 5 at the bottom are also insulated from each other ( image 3 ).

[0043] Then, on the source electrode 4 or the drain electrode 8 on one side of the groove side wall, a gold film is plated, and the gold particles formed after the annealing of the gold film are attached to the source electrode 4 or the drain electrode 8 of the side wall 2 ( Figure 4 ). The gold particles act as catalysts to guide the growth of the nanowires 7 .

[0044] Finally, GaN nanowires 7 are grown...

Embodiment 2

[0046] First, on the surface of the sapphire substrate, a groove structure (such as figure 1 ).

[0047] Secondly, the titanium nitride conductive film 3 (such as figure 2 ).

[0048] Then, utilizing an etching process, the conductive film 3 is divided, so that the source electrode 4 or the drain electrode 8 of the side wall 2 are insulated from each other, and the source electrode 4, the drain electrode 8 and the bottom gate electrode 5 are also insulated from each other ( image 3 ).

[0049] Then, on the source electrode 4 or the drain electrode 8 on either side of the groove, a nickel-gold film is plated, and after annealing, nickel-gold particles are formed to adhere to the source electrode 4 or the drain electrode 8 ( Figure 4 ). The particles act as catalysts to guide the growth of the nanowires 7 .

[0050] Finally, silicon nanowires 7 are grown on the titanium nitride film on the sidewall 2 by molecular beam epitaxy. Along with the growth of nanowire 7, nanowi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com