Surface-mounted permanent magnet motor structure

A permanent magnet motor, surface-mounted technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit, electrical components, etc., to achieve the effect of simple fastening method, convenient assembly and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

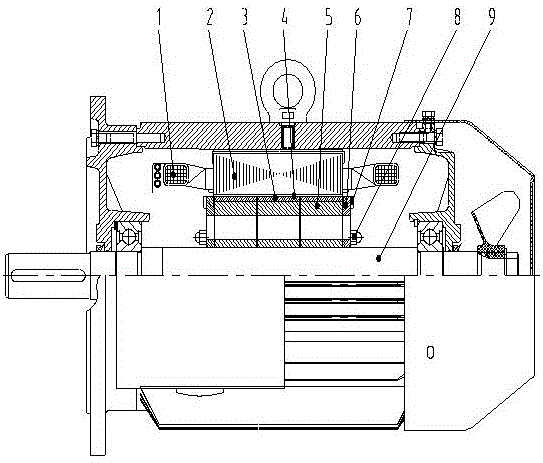

[0011] Such as figure 1 As shown, a surface-mounted permanent magnet motor structure, including a stator core 2 and a stator winding 1 connected to the stator core 2, is characterized in that a rotor core 5 is arranged between the stator core 2 and the shaft 9, and the rotor core 5 and the stator core The magnetic steel 3 and the latitude-free belt 4 are respectively arranged between the 2, and the rotor end plates 6 are respectively arranged on both lateral sides of the rotor core 5, and the self-cooling centrifugal blades 7 are arranged on the rotor end plates 6; the rotor core 5 is axially close to the shaft 9 Rotor tightening fasteners 8 are arranged on both sides.

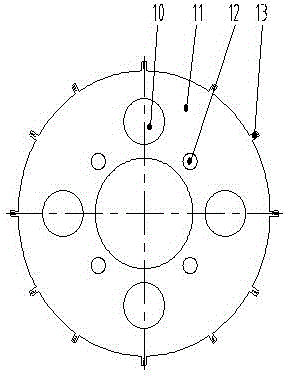

[0012] Such as figure 2 As shown, the rotor core 5 of the present invention is composed of several rotor punches 11, magnetic steel slots at an angle of 30° are evenly arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com