Asynchronous motor restart frequency sweep method and device

An asynchronous motor, restarting technology, used in motor control, starter parts, motor generator control and other directions, can solve the problem of inverter overcurrent, improve accuracy, reduce the step size of frequency search, and prevent overcurrent. flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

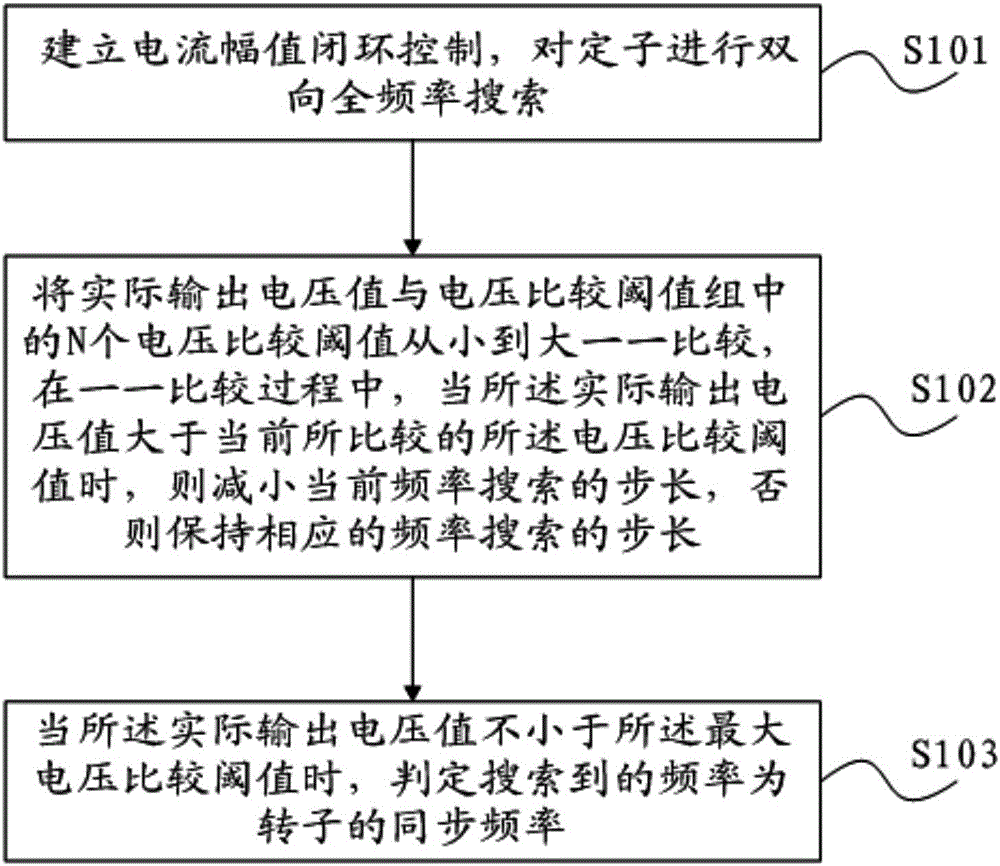

[0053] Embodiment 1 of the present invention provides a frequency sweeping method when restarting an asynchronous motor, as shown in the attached figure 1 Shown is a flow chart of a frequency sweep method when an asynchronous motor is restarted disclosed in Embodiment 1 of the present invention, the method includes:

[0054] S101: Establish a current amplitude closed-loop control, and conduct a two-way full-frequency search on the stator;

[0055] S102: During the two-way full-frequency search process, compare the actual output voltage value with the N voltage comparison thresholds in the voltage comparison threshold group from small to large one by one. During the one-to-one comparison process, when the actual output voltage value When it is greater than the current compared voltage comparison threshold, then reduce the current frequency search step size, otherwise keep the corresponding frequency search step size;

[0056] Wherein, the maximum voltage comparison threshold i...

Embodiment 2

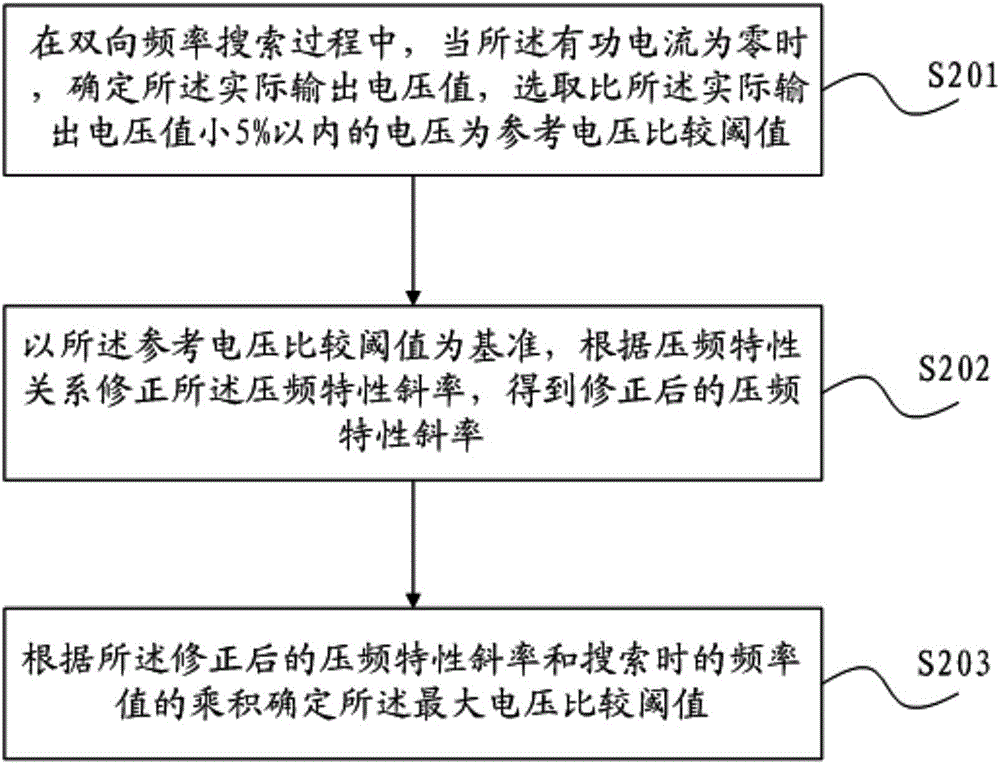

[0060] Based on the first embodiment of the present invention to provide a frequency sweep method when the asynchronous motor is restarted, as shown in the attached figure 2 As shown, in the technical solution disclosed in Embodiment 2 of the present invention, when the active current of the asynchronous motor is zero, if the maximum voltage comparison threshold is less than 95% of the actual output voltage value or greater than the actual output voltage value 105%, i.e. in the case where the maximum voltage comparison threshold is unreasonable, also includes:

[0061] S201: During the two-way frequency search process, when the active current is zero, determine the actual output voltage value, and select a voltage within 5% smaller than the actual output voltage value as a reference voltage comparison threshold;

[0062] S202: Based on the reference voltage comparison threshold, correct the voltage-frequency characteristic slope according to the voltage-frequency characterist...

Embodiment 3

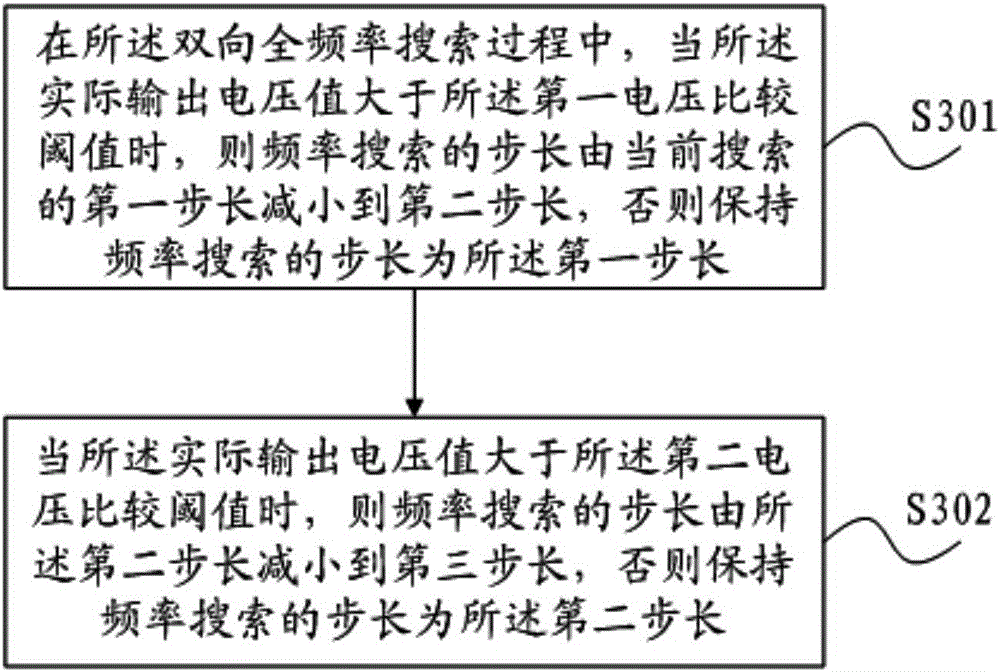

[0070] Based on the above-mentioned method for sweeping the frequency of an asynchronous motor during restart provided by Embodiment 1 of the present invention, the specific process of step S102 is correspondingly disclosed in the technical solution disclosed in Embodiment 3 of the present invention, including:

[0071] During the one-to-one comparison, when the actual output voltage value is greater than M 1 times the maximum voltage comparison threshold, the initial frequency search step size S 0 reduced to S 1 ; When the actual output voltage value is greater than M 2 times the maximum voltage comparison threshold, then the S 1 Reduced to S on the basis of 2 ;Continue to compare, when the actual output voltage value is greater than M i When times the maximum voltage comparison threshold, where 3≤i≤N-1, then the previous frequency search step S i-1 Reduced to S on the basis of i ; among them, S 0 , S 1 ......S i-1 , S i ......S N-1 The value of is a positive integ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com