Axial-flow type peanut picker

A peanut picking machine, axial flow technology, applied in agricultural machinery and tools, threshing equipment, applications, etc., can solve the problems of poor axial conveying capacity, low fruit picking efficiency, entanglement of seedlings and tendrils, and reduce entanglement and peanut crushing The effect of low efficiency, avoiding winding and clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

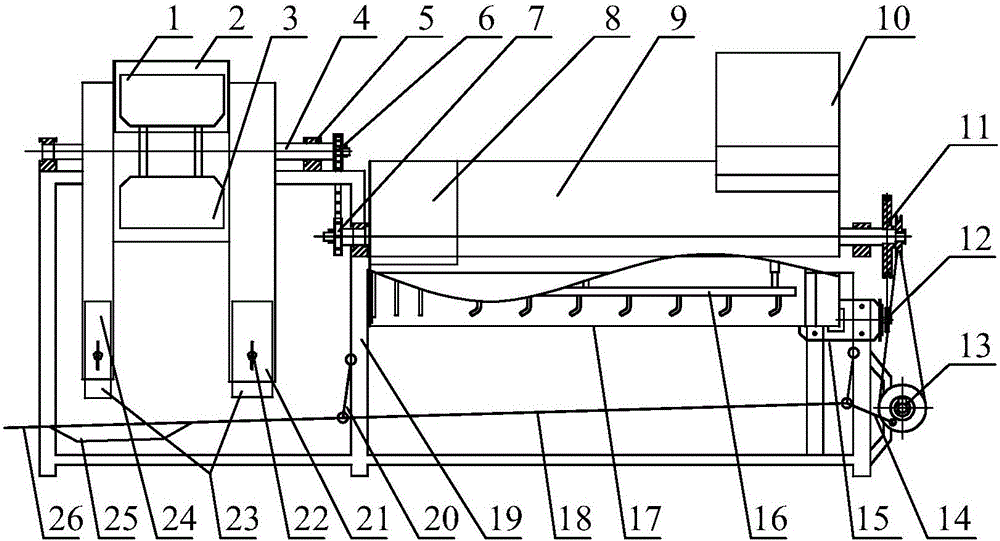

[0027] Embodiment 1: as figure 1 As shown, a kind of axial-flow peanut picking machine of the present invention comprises frame 19, motor 15, transmission device, fruit picking device, cleaning device, feeding port 10, stem row port 8 and discharge port 26, and described fruit picking The device comprises a fruit-picking cylinder 16, a concave screen 17 and a top cover 9, wherein the central axis 34 of the fruit-picking cylinder 16 is installed on the frame 19, the concave screen 17 is installed on the frame 19 and is located below the fruit-picking cylinder 16, and the top cover 9 is fixed. Positioned on the frame 19 above the fruit picking cylinder 16, the feeding port 10 and the stem opening 8 are fixed on both sides of the top cover 9, and the space surrounded by the concave screen 17 and the top cover 9 is the fruit picking room.

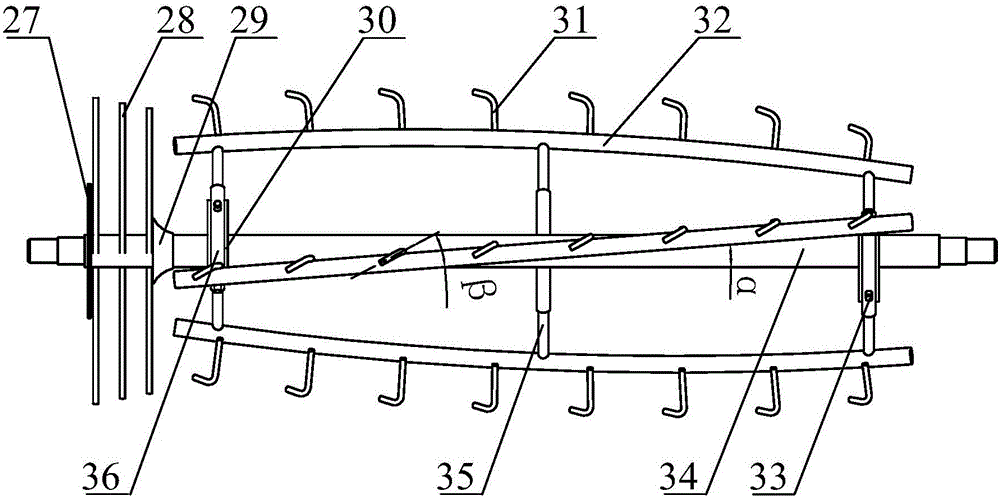

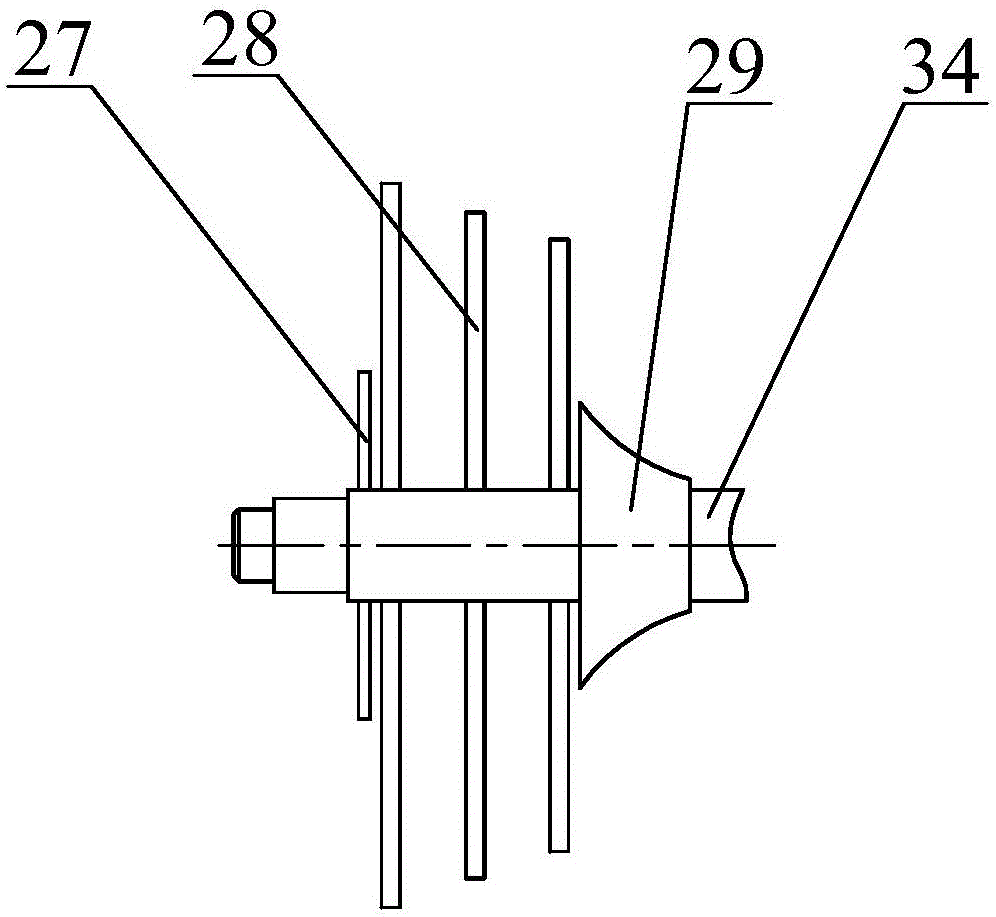

[0028] Such as figure 2 As shown, the fruit picking cylinder 16 includes a central axis 34, a fixed frame 30 arranged at both ends of the ce...

Embodiment 2

[0035] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the fruit picking rod 32 in this embodiment is an arc rod, and the angle α inclined to the central axis 34 is 15°. The included angle β between the fruit-picking tooth 31 and the normal direction of the contact point with the central axis 34 is 25, and the radial gap between the fruit-picking tooth 31 outer edge on the fruit-picking bar 32 and the concave screen 17 and the top cover 9 is 20mm. The bending angle γ at the end of the fruit picking teeth 31 is 75°. The anti-wrapping grass structure is provided with two rows of grass teeth 28 . The central angle of the arc of the concave screen 17 is 180°. Grass row tooth 28 is that the end bending angle θ is 125 °, and the angle η between the grass row tooth axis and the contact point normal direction of the main shaft is 25 °.

Embodiment 3

[0036] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the fruit picking rod 32 in this embodiment is a straight rod, and the angle α inclined to the central axis 34 is 20°. The included angle β between the fruit picking tooth 31 and the normal direction of the contact point with the central axis 34 is 30°, and the radial gap between the fruit picking tooth 31 outer edge on the fruit picking bar 32 and the concave screen 17 and the top cover 9 is 30mm. The bending angle γ at the end of the fruit picking teeth 31 is 90°. The anti-wrapping grass structure is provided with two rows of grass teeth 28 . The central angle of the arc of the concave screen 17 is 230°. The grass-discharging teeth 28 have an end bending angle θ of 145°, and the included angle η between the grass-discharging tooth axis and the contact point normal direction of the main shaft is 30°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com