Hollow screw for restoring damaged ligaments or muscle tendons

A cannulated screw and tendon technology, applied in the field of medical devices, can solve the problems of increasing the psychological burden of patients with foreign body rejection, prolonging the operation time, and complicated surgical operations, so as to avoid foreign body rejection, simplify surgical operations, and reduce workload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

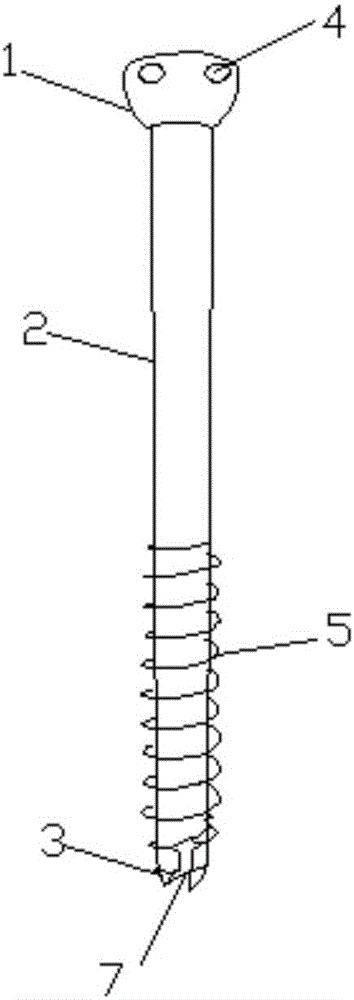

[0020] The present invention is a hollow screw for repairing damaged ligament or tendon, such as figure 1 and figure 2 As shown, it includes a hollow screw body, the hollow screw body is composed of a nail head 3, a nail body 2 and a nail tail 1 connected in sequence, a groove 6 is opened in the upper middle of the nail tail 1, and a groove 6 is opened on the outer wall of the nail tail 1. There is a suture through hole 4, which is used for suturing and repairing the damaged ligament or tendon through the suture thread; the front end of the nail head 3 is open, and the nail head 3, the nail body 2 and the groove 6 are connected to form a The through space is used for the coaxial passage of the guide pin.

[0021] The stitching through hole 4 is opened radially and communicates with the groove 6 . The number of suture through holes 4 is 6, and they are set on the side walls corresponding to the six sides of the groove 6 respectively, and the outer axial direction of the nail...

Embodiment 2

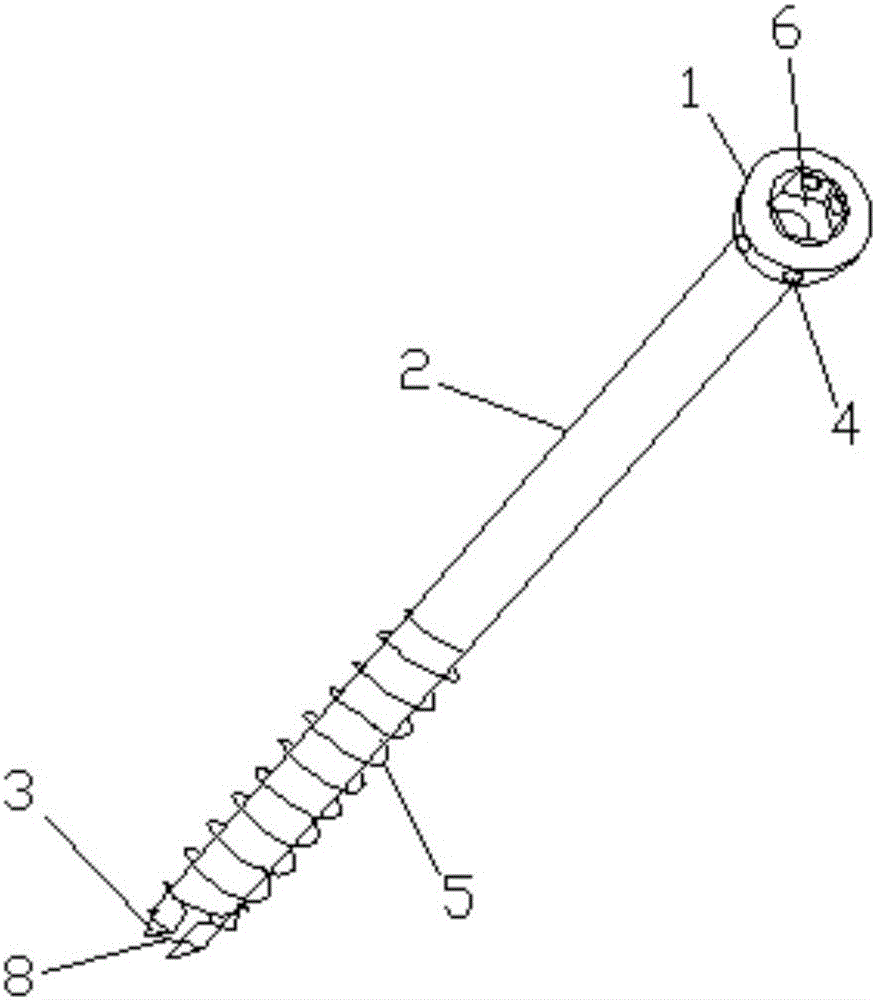

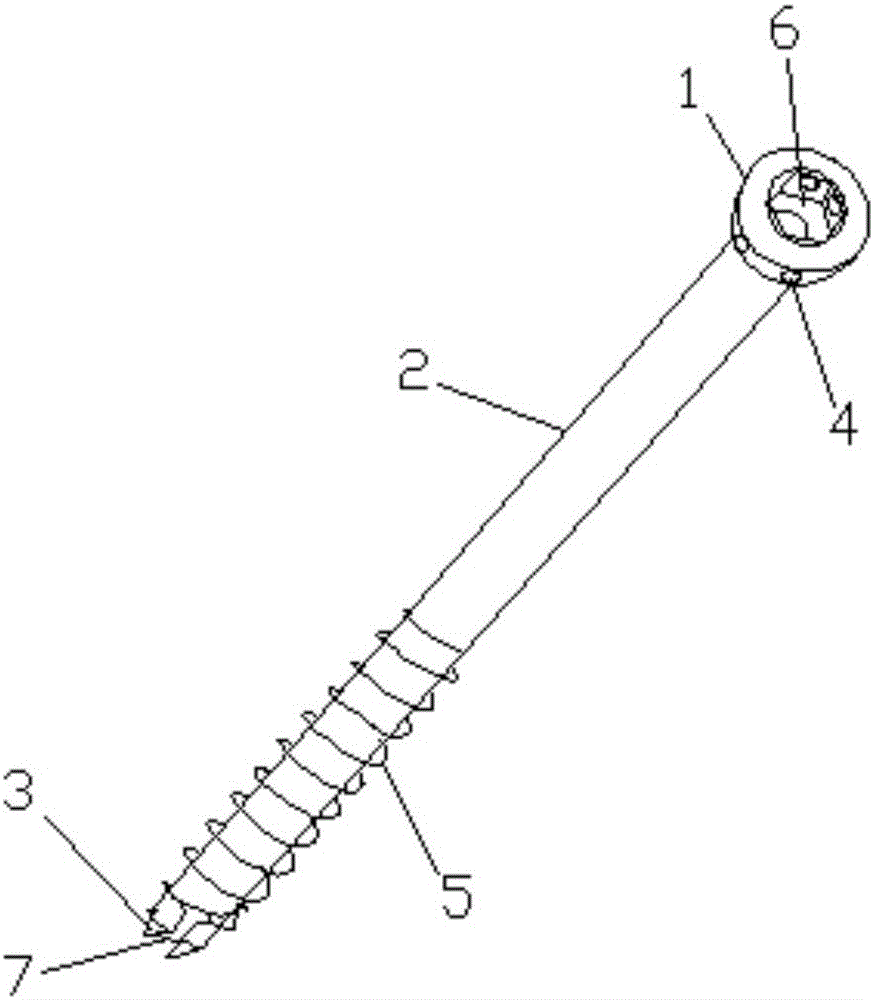

[0025] The present invention is a hollow screw for repairing damaged ligament or tendon, such as figure 1 and image 3 As shown, it includes a hollow screw body, and the hollow screw body is composed of a nail head 3, a nail body 2 and a nail tail 1 connected in sequence, and a groove 6 is opened in the upper middle part of the nail tail 1, and the nail tail 1 A suture through hole 4 is opened on the outer side wall of the outer wall, and the suture through hole 4 is used for suturing and repairing damaged ligaments or tendons to pass through; the front end of the nail head 3 is open, and the nail head 3, nail body 2 and The grooves 6 communicate with each other to form a through space for coaxial passing of the guide pin. The suture through hole 4 is opened axially and communicates with the top wall of the nail tail 1 . When the used suture needle has a radian, the suture needle can pass through smoothly, saving operation time. The suturing through hole 4 is used for sutur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com