Preparation method and application of silk fibroin compound hydroxyapatite material

A technology of compounding hydroxyapatite and hydroxyapatite, which is applied in the fields of medical science, prosthesis, tissue regeneration, etc., to achieve the effect of accelerating repair, treating continuous bone defects, and avoiding rejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of silk fibroin aqueous solution (SF): silkworm cocoons were steamed with 0.005wt% sodium carbonate aqueous solution for 0.5h, and then degummed. The degummed silk was dissolved in 9.3mol / L lithium bromide solution, and the silk fibroin solution dissolved in lithium bromide was dialyzed with distilled water After 3 days, concentrate and process to obtain silk fibroin aqueous solutions with different concentrations, the concentrations of which are 6wt%, 9wt% and 12wt% respectively.

[0038] The specific concentration steps are as follows: put the purified low-concentration silk fibroin solution into a dialysis bag with a molecular weight cut-off of 8,000-14,000; hang the dialysis bag with the silk fibroin solution in an environment of 1-5°C, and use a fan to carry out the process. Purging accelerates the loss of water in the solution; take out the silk fibroin solution after fan blowing for 36 hours, and use the drying method to determine the concentration of ...

Embodiment 2

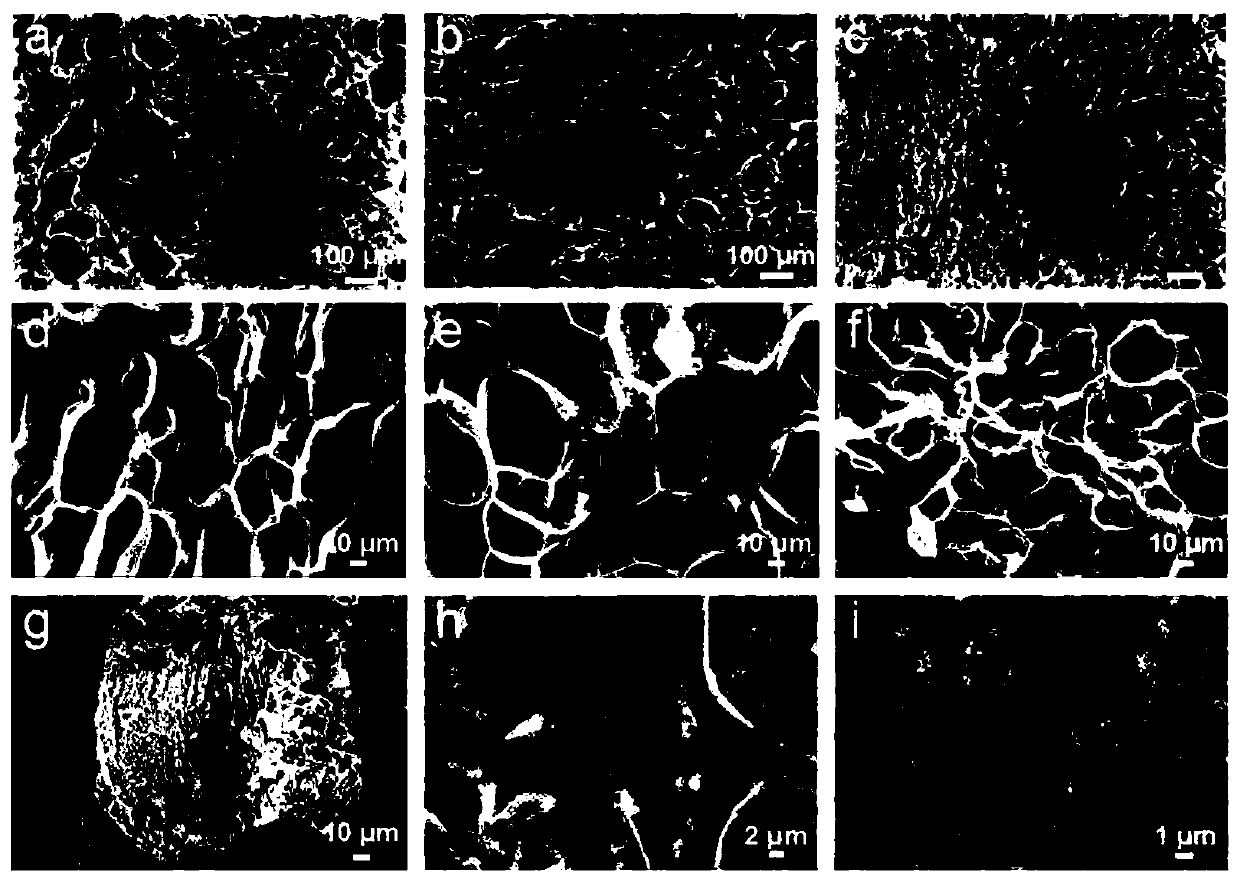

[0043] Scanning electron microscopy (SEM) was used to characterize the cross-sectional morphology characteristics of the three groups of silk fibroin composite hydroxyapatite materials synthesized in situ in Example 1. The sample preparation method is as follows: take unmineralized and mineralized silk fibroin film samples, brittle in liquid nitrogen, and then dry them under vacuum at -40°C, take appropriate size sample fragments, spray gold, and pass through the field. The hydrogel morphology was observed and photographed with an emission scanning electron microscope (FESEM, Zeiss, Germany), and the accelerating voltage of the scanning electron microscope was 7 kV. figure 2 The a-c shown are low-magnification (100×) cross-sectional scanning electron micrographs of enzyme-crosslinked silk fibroin materials prepared from raw material solutions with three concentrations of 6wt%, 9wt%, and 12wt%, and d-f are corresponding high-magnification (500×) The scanning electron micrograp...

Embodiment 3

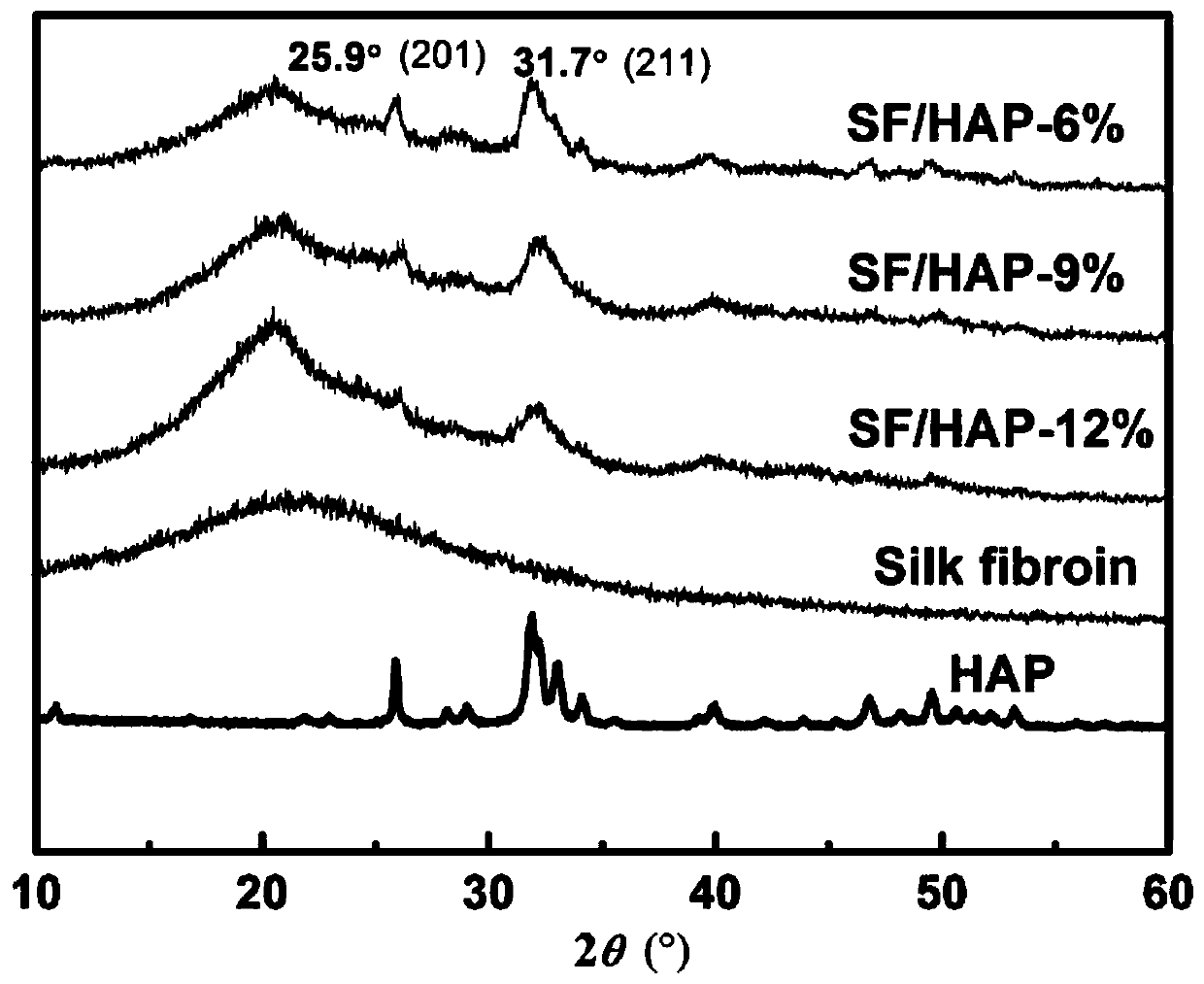

[0045] The three groups of silk fibroin-composite hydroxyapatite materials prepared in Example 1 were respectively cut into powders, and were subjected to X-ray diffraction detection respectively to study the change of composite hydroxyapatite in the composite materials to the microscopic crystal morphology of the materials. image 3 As shown, the results show that the raw material of silk fibroin is an amorphous structure, and a certain crystallization (β-fold) appears after methanol regeneration. However, after the in situ mineralization of hydroxyapatite on the silk fibroin raw material, the characteristic peak of hydroxyapatite appeared, indicating the existence of hydroxyapatite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com