Hollow ball body and manufacturing method as well as movable ball adopting hollow ball body

A hollow sphere and a production method technology, which are applied to inflatable hollow spheres, sports accessories, balls, etc., can solve the problems of easy wrinkling and loosening of the edge of the gauze, bulging and out-of-roundness of the sphere, and air pressure deformation, etc. The effect of high strength, good roundness and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

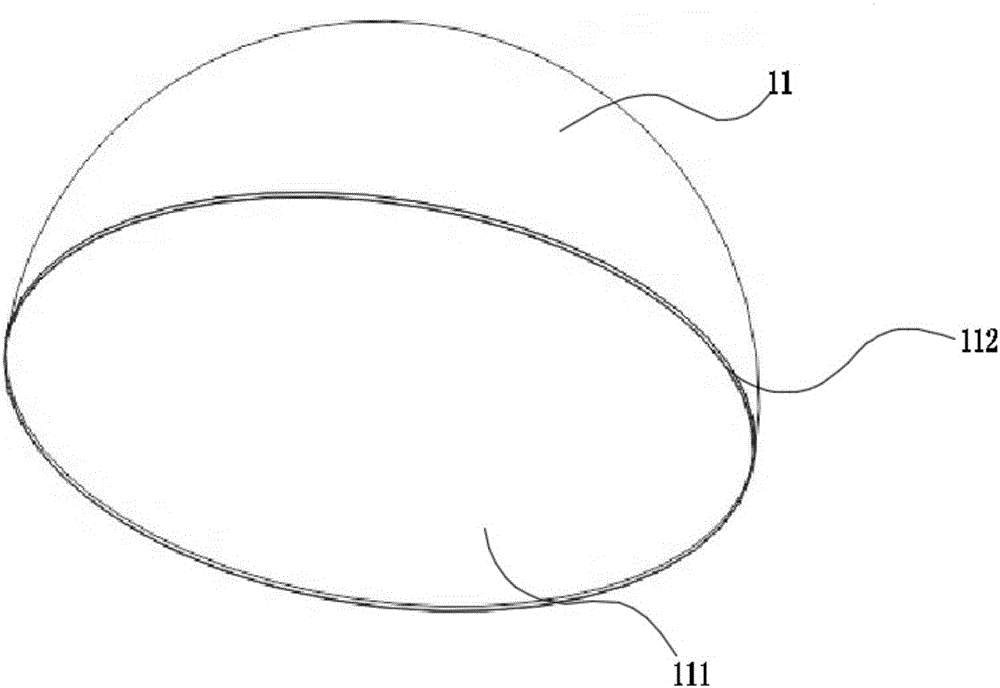

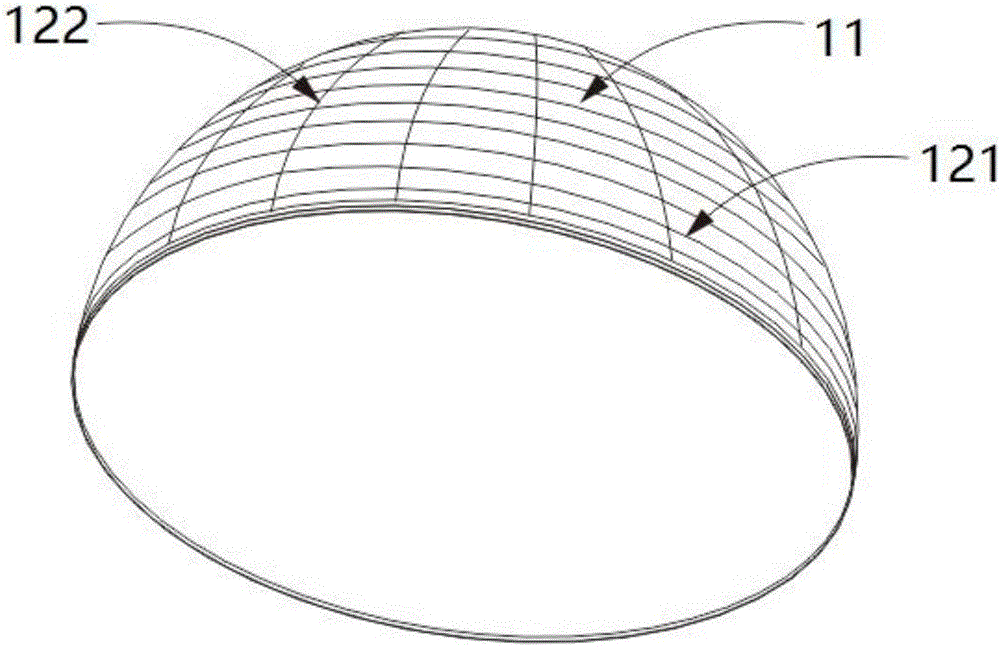

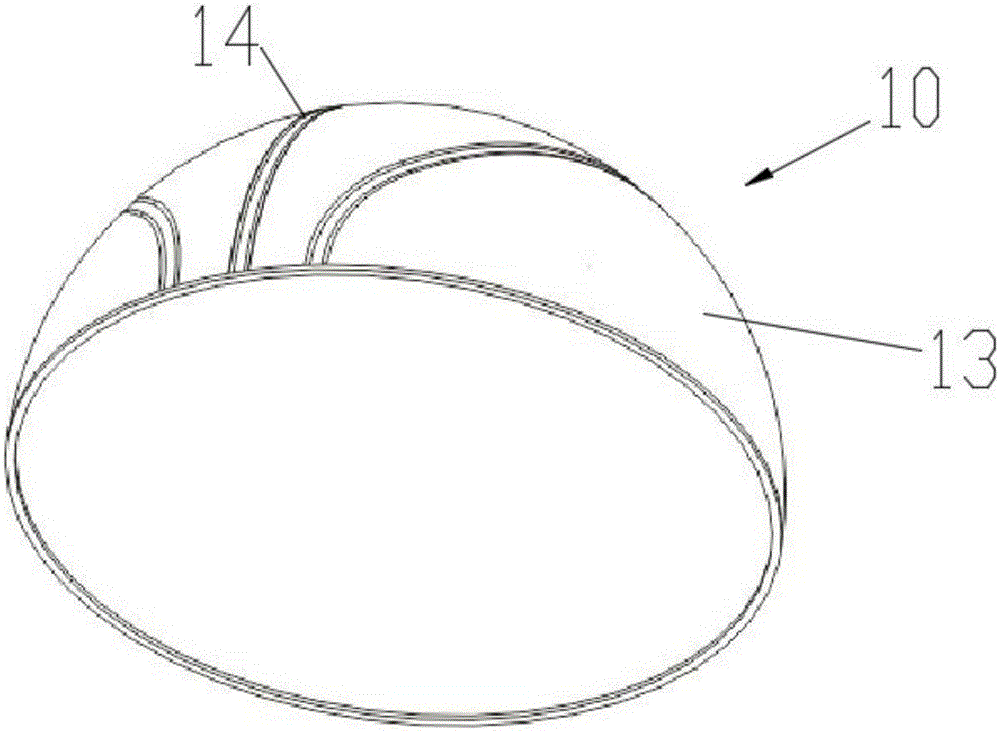

[0042] refer to Figure 1-5 A hollow sphere 100 described in this embodiment includes two hemispherical shells 10; each hemispherical shell 10 includes an embryo body 11, a gauze and an outer shell 13; the embryo body 11 is molded by chemical fiber gauze through heating The method is formed into a hemispherical embryo body, the embryo body 11 has a hemispherical cavity 111, and the hemispherical cavity 111 has an opening 112 that runs through the end face where the center of the embryo body is located; the gauze is wound on the embryo body 11 A plurality of weft yarns 121 on the outer surface and a plurality of warp yarns 122 wound on the outer surface of the embryo body 11 constitute; the shell 13 is a hemispherical shell injection-molded on the outer surface of the gauze of the embryo body 11 by a thermoplastic elastic material; The two hemispherical shells 10 are thermally welded to form a closed hollow sphere 100 .

[0043] Preferably, the gauze is fixedly bonded to the o...

Embodiment 2

[0051] The characteristics of this embodiment are: in the manufacturing method of the hollow sphere, in step 2), when winding the weft yarn and the warp yarn, the second fixing method of the yarn is: the yarn is drawn out from the hot-melt glue nozzle, and the hot-melt glue automatically Viscose yarn is formed after injection in the nozzle, and the viscose yarn is compounded with yarn and attached to the embryo body; others are the same as in Example 1.

Embodiment 3

[0053] The characteristics of this embodiment are: in step 2), the winding method of winding the warp yarn: by moving the hot melt glue nozzle along the longitude direction of the embryo body, the yarn compounded with viscose yarn is wound on the outer surface of the embryo body , forming a number of warp yarns; the winding method of winding weft yarns: the embryo body rotates and gradually rises and falls, so that the yarn is automatically and continuously wound on the outer surface of the embryo body to form several weft yarns. Others are identical with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com