Industrial separation method

A separation method and industrial technology, applied in chemical instruments and methods, fructose production, sugar production, etc., can solve the problems of high energy consumption, environmental pollution, etc., and achieve the effect of reducing operating costs and high-efficiency separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

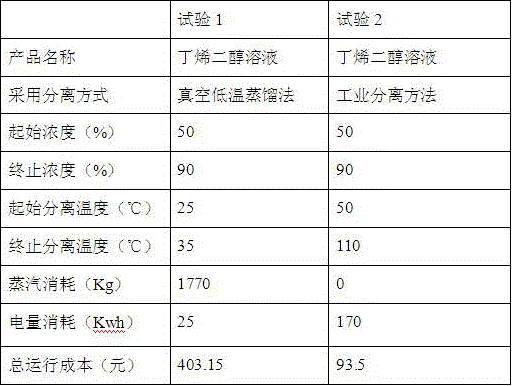

[0024] A kind of industrial separation method of butylene glycol solution, comprises the following steps:

[0025] Step 1. Put the 50% butylene glycol solution into the vacuum separation tank for heating. The butylene glycol solution continuously absorbs heat and raises the temperature. When the temperature reaches 25°C, the water in the solution continuously vaporizes to form The water vapor is separated from the butylene glycol solution, and the butylene glycol solution is slowly concentrated;

[0026] Step 2, the water vapor in step 1 is sucked into the molecular compression mechanism for multi-stage compression under the action of the condensed water with a water pressure of 1Mpa and a water flow of 200m / s. After the compression is completed, the kinetic energy and temperature of the condensed water are reduced and Entering the condensed water buffer tank, the kinetic energy and temperature of the water vapor rise to form secondary steam, which is used to provide heat for ...

Embodiment 2

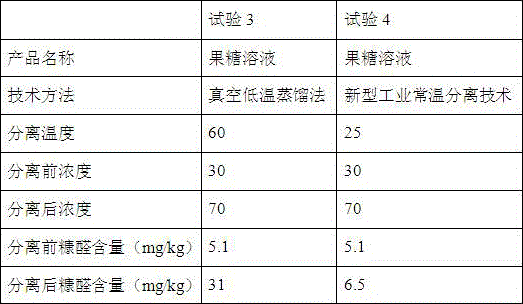

[0041] A kind of industrial separation method of fructose solution, comprises the following steps:

[0042] Step 1, put the 30% fructose solution into the vacuum separation tank for heating, the butylene glycol solution continuously absorbs heat and raises the temperature. When the temperature reaches 25°C, the water in the solution is continuously vaporized to form water vapor and The fructose solution is separated, and the fructose solution is slowly concentrated;

[0043]Step 2, the water vapor in step 1 is sucked into the molecular compression mechanism for multi-stage compression under the action of the condensed water with a water pressure of 1Mpa and a water flow of 200m / s. After the compression is completed, the kinetic energy and temperature of the condensed water are reduced and Entering the condensed water buffer tank, the kinetic energy and temperature of the water vapor rise to form secondary steam, which is used to provide heat for the evaporation and separation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com