Atomizing device capable of increasing atomization quantity

A technology of atomization device and atomization amount, which is applied to spray devices, liquid spray devices, etc., can solve the problems of decreased atomization efficiency, influence of atomization amount, and reduction of effective atomization range, so as to reduce energy consumption and improve atomization. Quantitative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable your review committee members to clearly understand the content of the present invention, only the following descriptions are used together with the drawings, please refer to them.

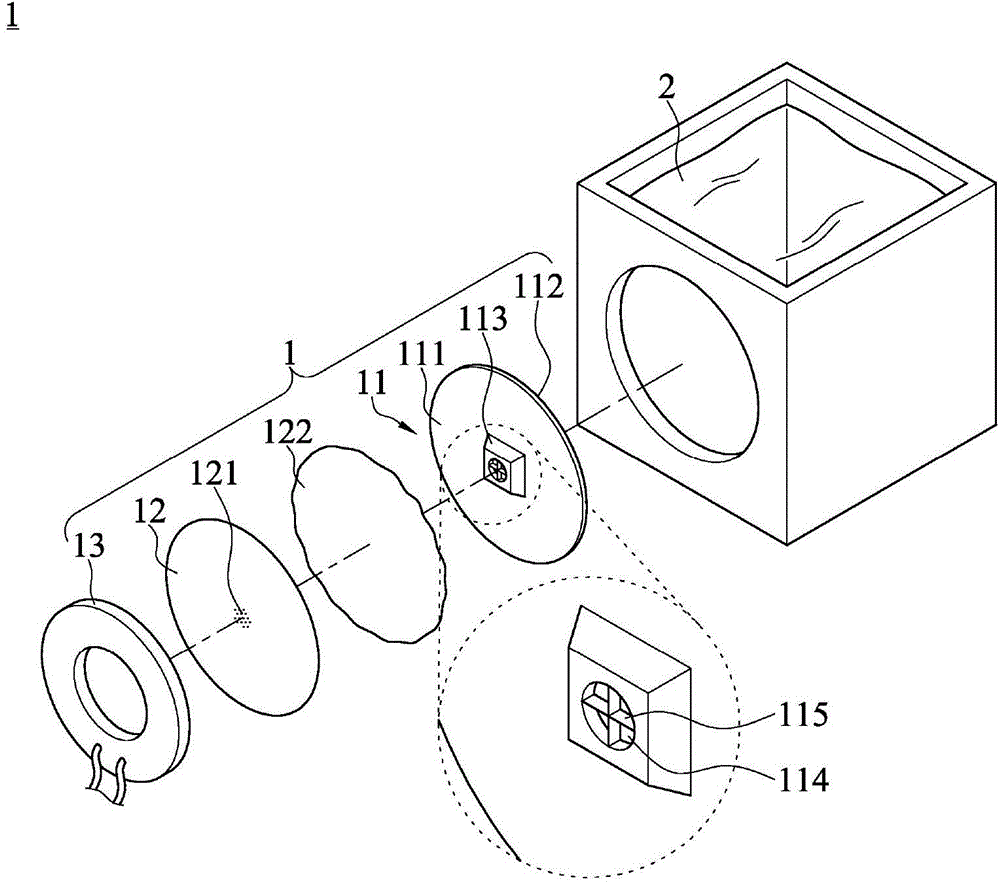

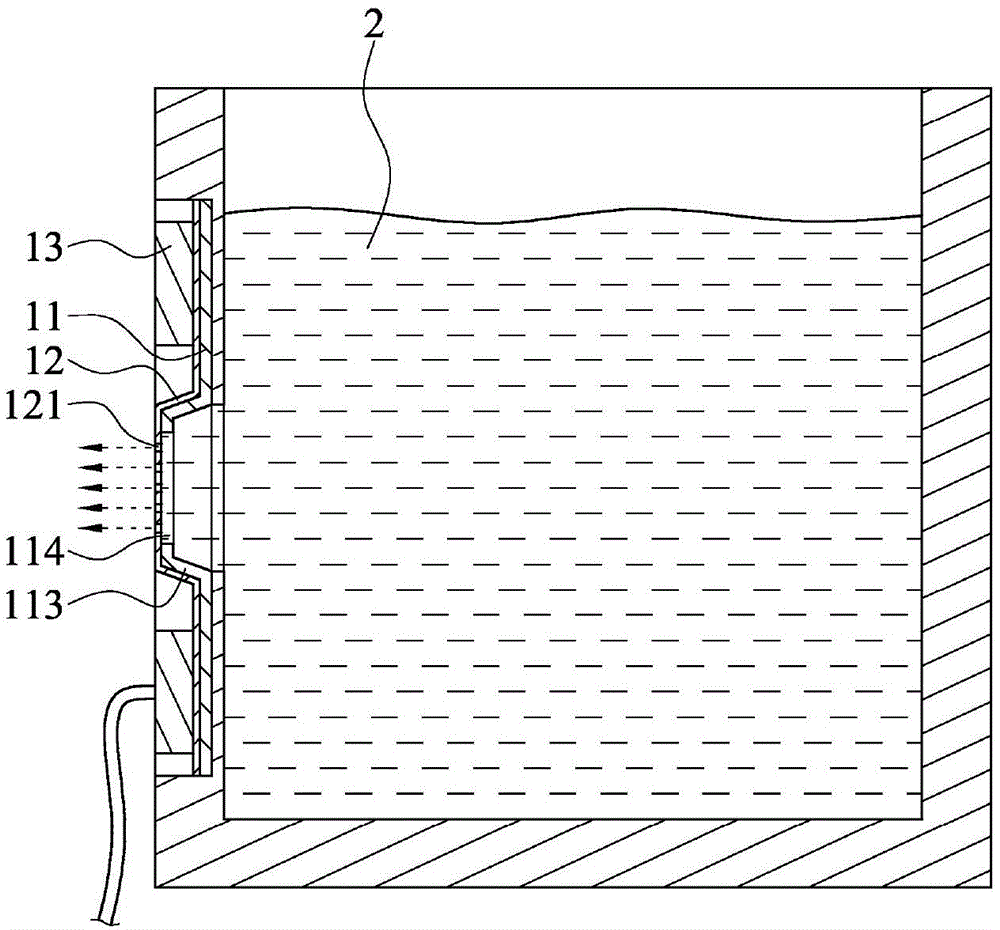

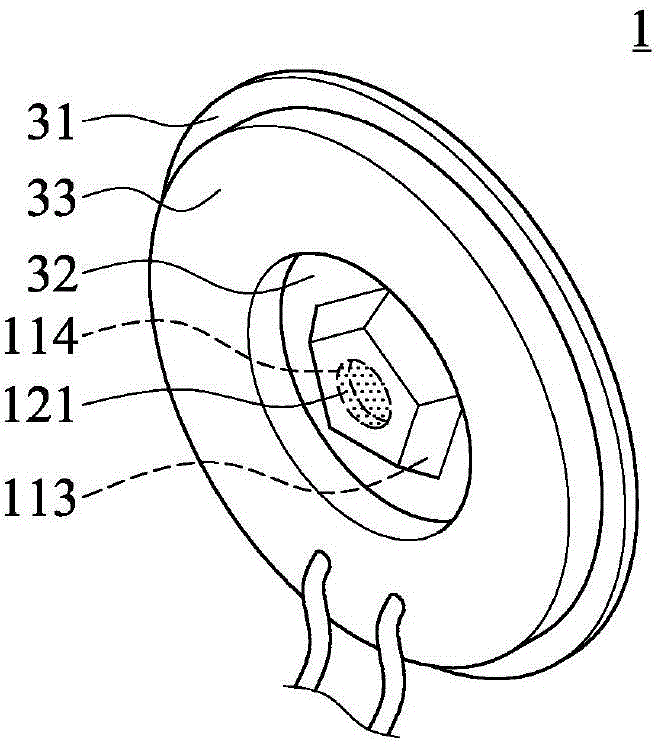

[0038] see figure 1 , figure 2 , is a three-dimensional exploded view and a combined sectional view of the first embodiment of the present invention. As shown in the figure, the atomization device 1 that can increase the atomization amount represented by the first embodiment of the present invention includes: a structural sheet 11 , an orifice sheet 12 and a piezoelectric ring 13 .

[0039] Wherein the structural sheet 11 is made of stainless steel sheet material, and it has a liquid outlet surface 111 and a liquid inlet surface 112, the structural sheet 11 is made to protrude toward the liquid outlet surface 111 by stamping technology to form a bulge 113, A perforation 114 is provided at the center of the raised portion 113, and the raised portion 113 is formed into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com