Non-sinusoidal oscillation device of continuous casting crystallizer and oscillation method thereof

A continuous casting crystallizer and vibrating device technology, applied in the field of continuous steel casting, can solve the problems of affecting control accuracy, easy wear, poor bearing and impact resistance, etc., and achieve the effect of simple control, high reliability and large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail:

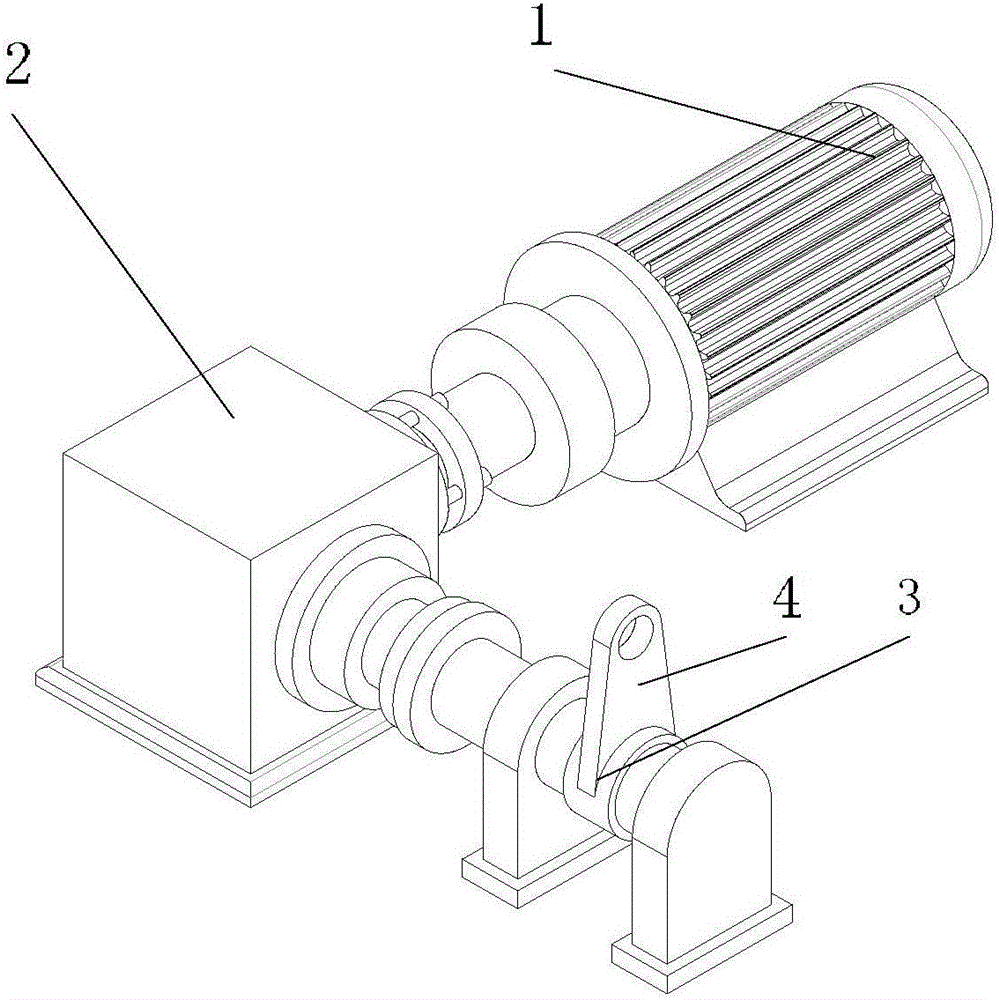

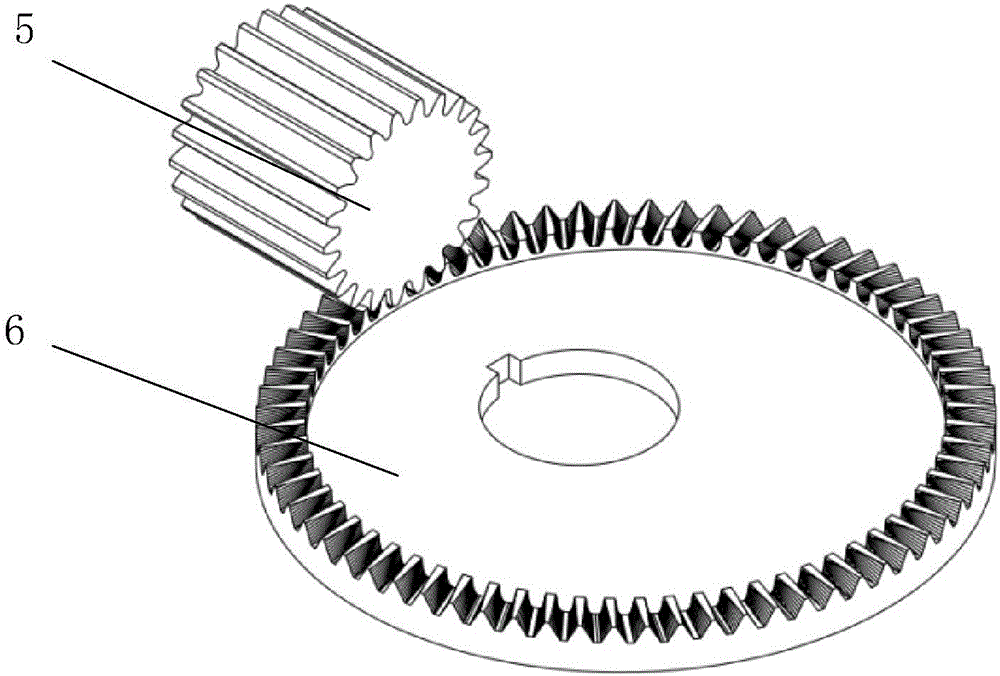

[0028] The invention provides a continuous casting crystallizer non-sinusoidal vibration device, as attached figure 1 and figure 2 As shown, inside the housing of the deceleration transmission 2, there is a deceleration and transmission integrated gear mechanism composed of the driving spur gear 5 and the driven non-circular gear 6, the axis of the driving spur gear and the driven non-circular surface The gear axes intersect vertically, and the number of teeth of the driven non-circular gear is 3 to 8 times that of the driving spur gear. The output shaft of the variable frequency motor 1 is connected with the driving spur gear through a coupling, the driving spur gear meshes with the driven non-circular gear, and the driven non-circular gear is connected with one end of the eccentric shaft 3 through a coupling , the eccentric shaft is hinged with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com