A kind of manipulator automatic material sorting type cutting device

A technology of cutting device and manipulator, which is applied in the directions of driving device, nibbling cutting device, shearing device, etc. It can solve the problems that ordinary manipulators cannot complete long-distance transfer due to short grasping stroke, and cannot locate the exact position of cutting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

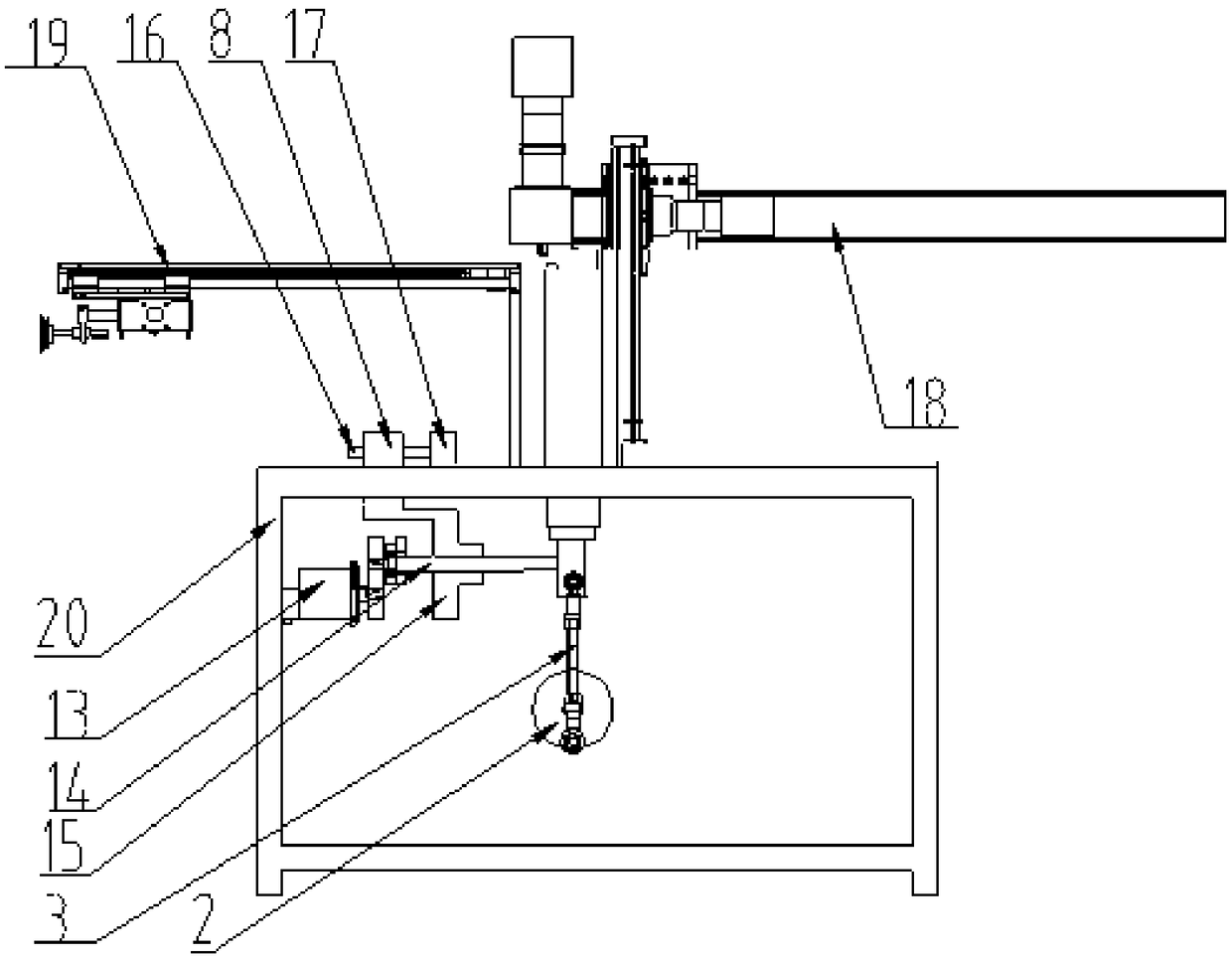

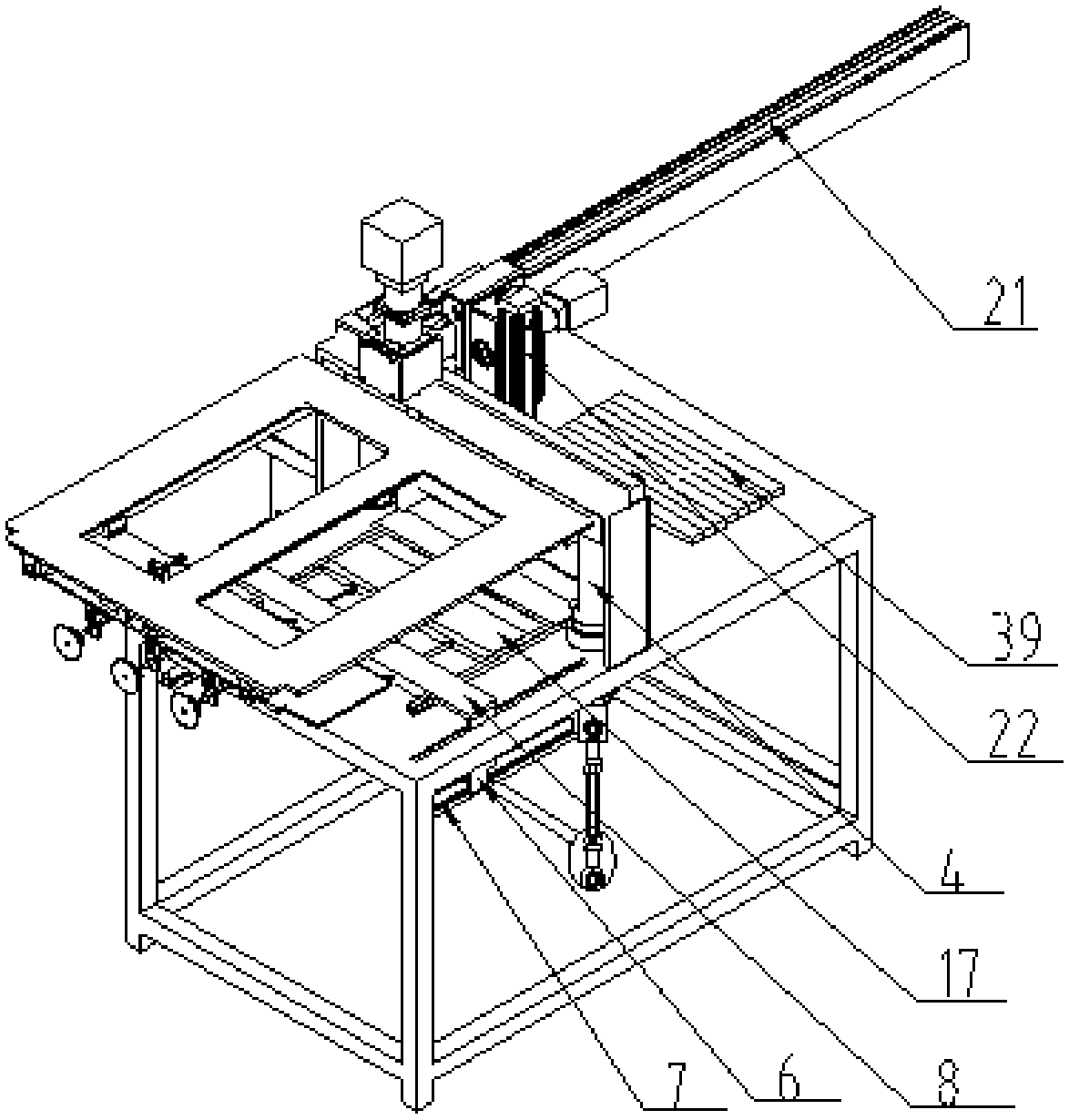

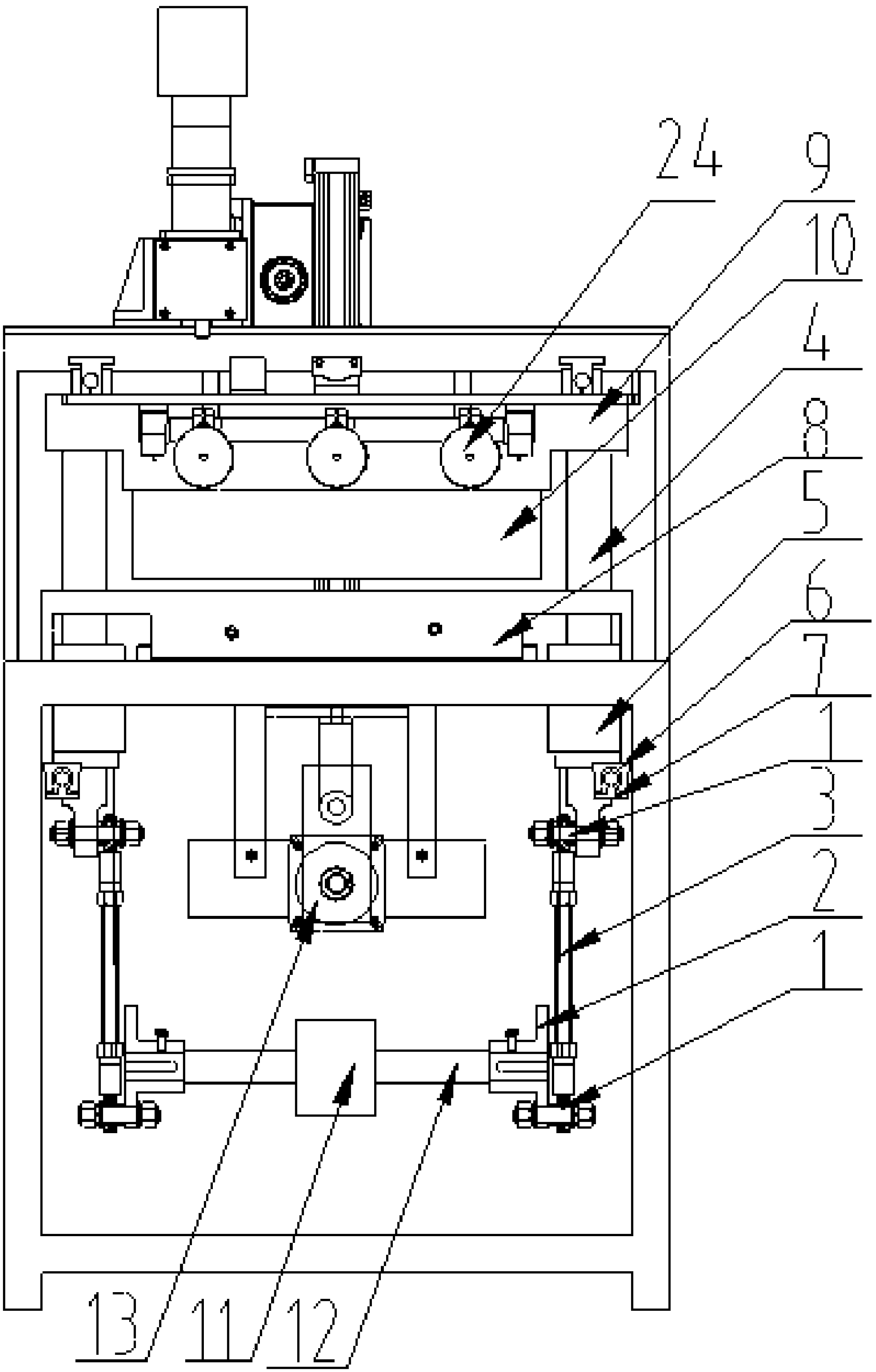

[0016] The manipulator automatic material sorting cutting device according to the present invention includes a frame 20 on which a cutter device, a Cartesian coordinate transfer manipulator 18 and a pneumatic two-point swing manipulator 19 are arranged.

[0017] Among them, the pneumatic two-point swing manipulator 19 is installed at the feeding position of the manipulator automatic material sorting type cutting device, and the Cartesian coordinate transfer manipulator 18 is installed at the material discharge position of the manipulator automatic material sorting type cutting device.

[0018] Such as Figure 1-5 As shown, the manipulator automatic material sorting cutting device according to the present invention has the following components: stud 1, turntable 2, transmission rod 3, guide post 4, guide sleeve 5, slider 6, slide rail 7, push Rod mounting plate 8, cutter mounting plate 9, cutter 10, cutter power device 11, transmission shaft 12, push plate power device 13, lead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com