System with double inner liquid spraying tool cathodes and electrolytic grinding and milling method of system with double inner liquid spraying tool cathodes

A tool cathode and electrolyte technology, which is applied to the double internal jet tool cathode system and the field of electrolytic milling, can solve the problem of prolonging the processing time, changing the error and poor machining allowance, and reducing the machining accuracy and machining efficiency of the electrolytic milling. and other problems, to achieve the effect of improving processing efficiency and processing accuracy, and increasing processing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

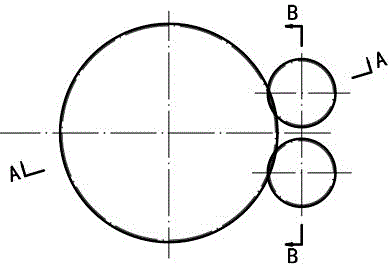

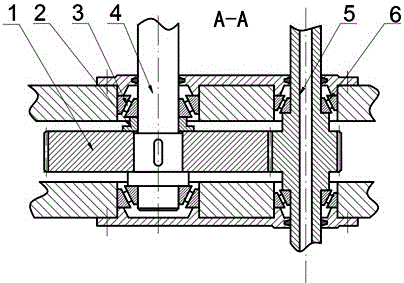

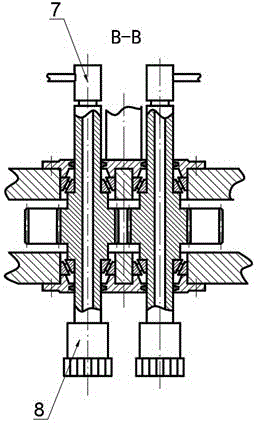

[0018] according to figure 1 , figure 2 and image 3 As shown, the main shaft transmission device of the cathodic electrolytic milling of the double internal spray tool is composed of the following parts: the main shaft 4 of the electrolytic milling machine tool drives two hollow transmission shafts 5 to rotate through the transmission spur gear set 1 at the same time, and then the transmission shaft 5 drives The swivel joint 6 at its top rotates together with the water stop chuck 7 at its end. Both the machine tool 4 and the drive shaft 5 are supported by two angular contact bearings 3. The spur gear set is respectively externally meshed with two driven small spur gears of the same size through a driving large spur gear. The two small spur gears are not in contact and have a certain distance distance, the gear is positioned by the shoulder, sleeve 2 and key, and installed as standard.

[0019] Combine below figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Il...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com