Automatic sliding column polishing machine

A polishing machine, fully automatic technology, used in surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc. Fast speed, high degree of automation, and the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

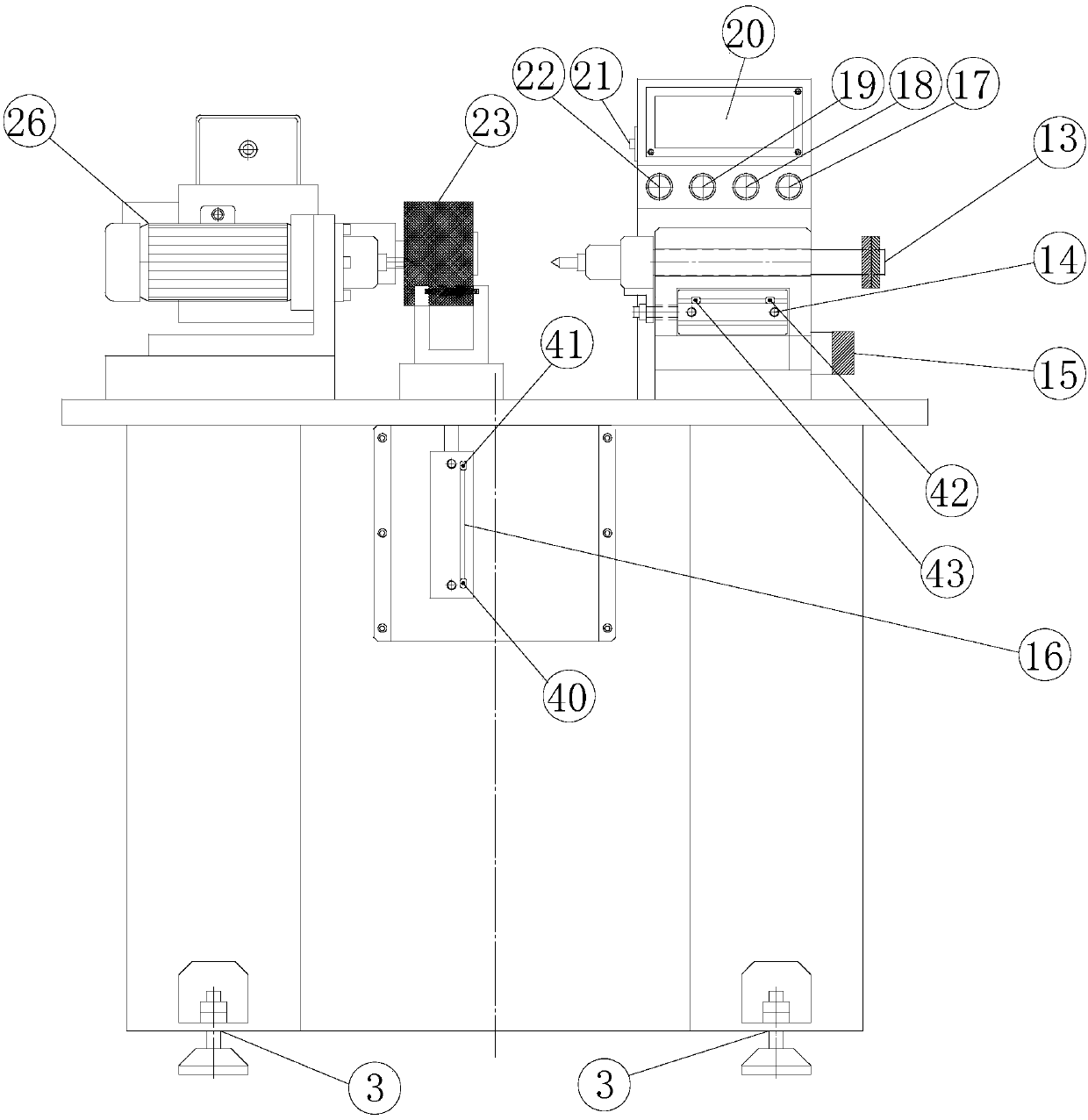

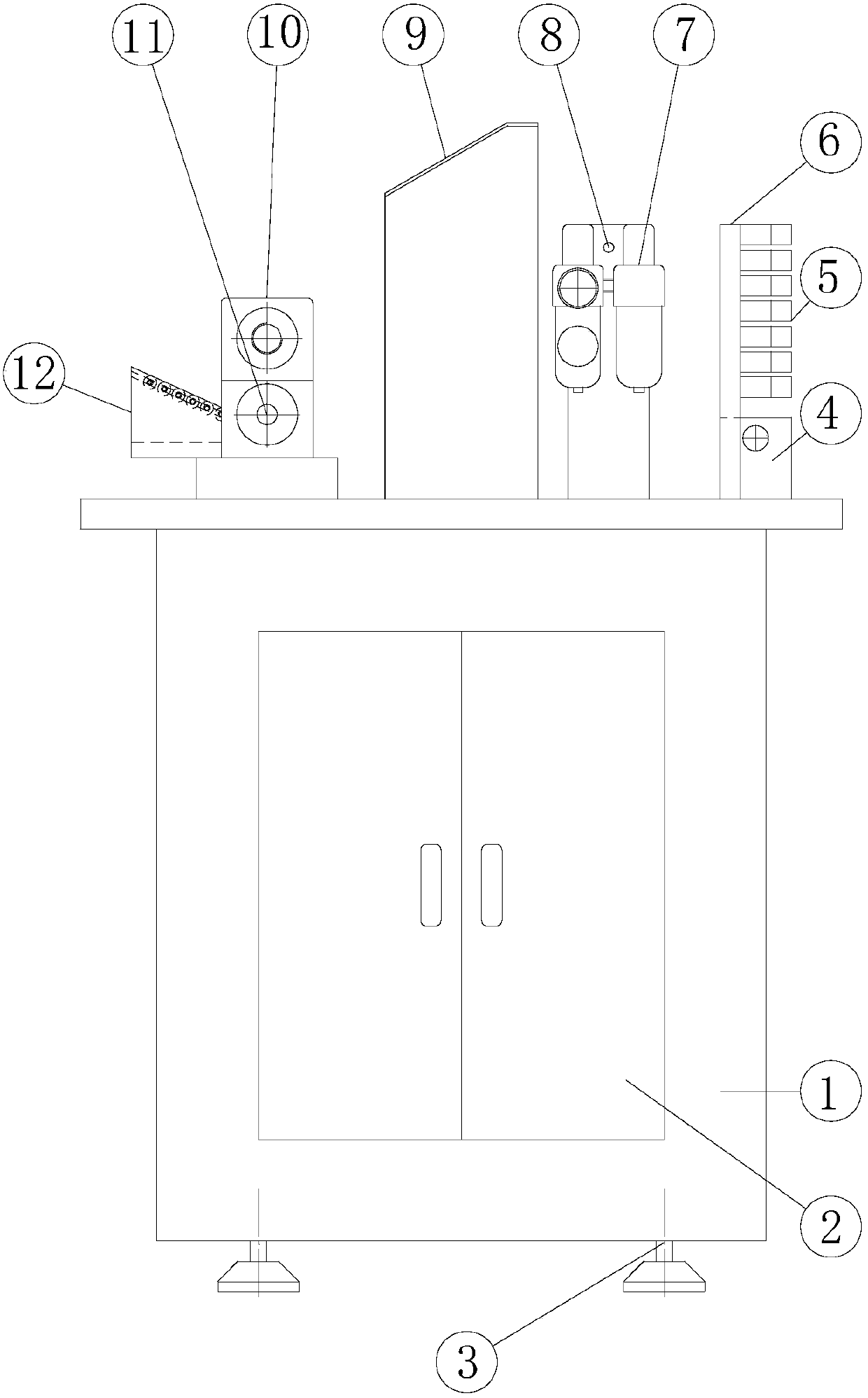

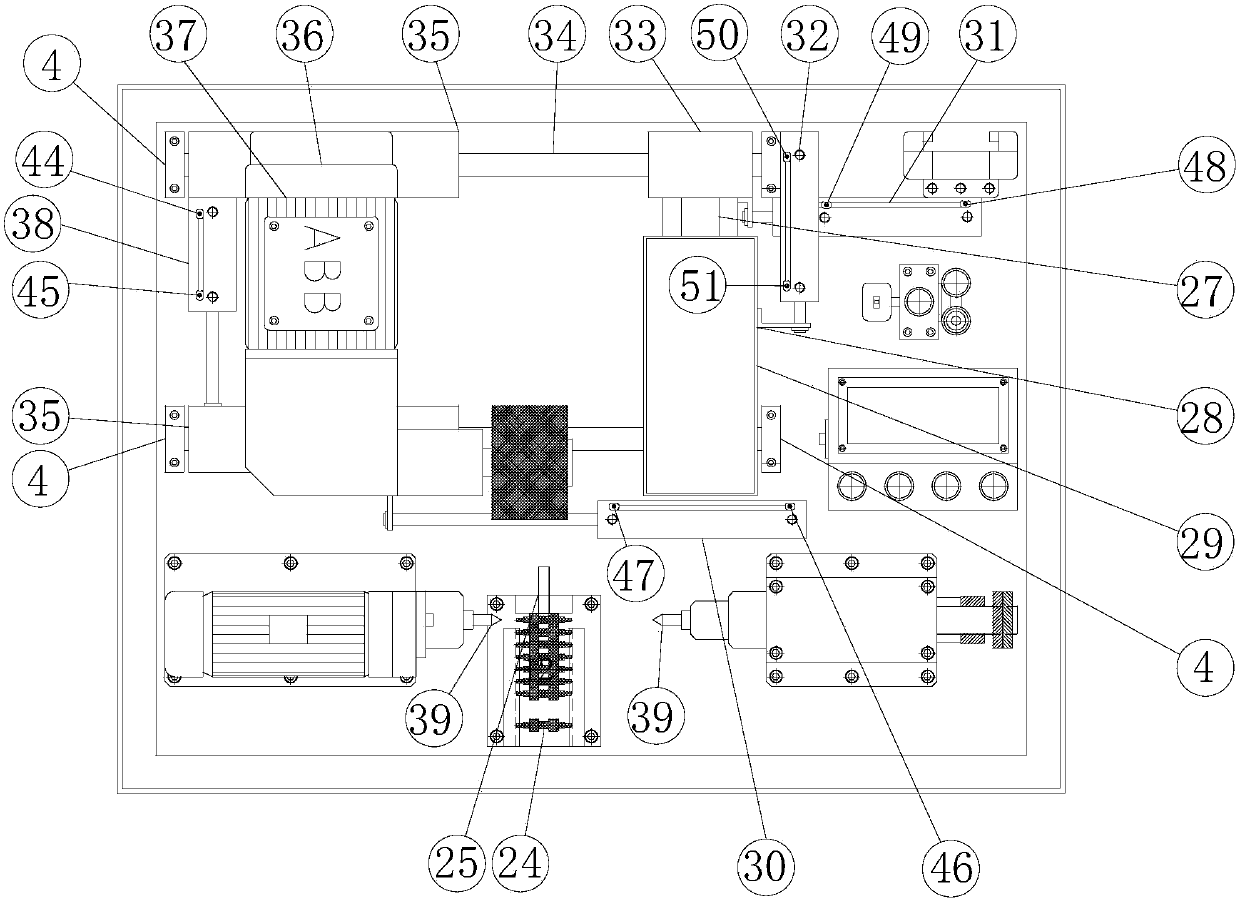

[0030] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

[0031] as attached figure 1 To attach image 3As shown, the present invention comprises: machine base 1, power transmission mechanism, feeding device, discharging device and electric control system, and power transmission mechanism, feeding device, discharging device are all installed on the machine base 1, and feeding device is used In order to supply and fix the processed spool 24, the power transmission mechanism is equipped with a nylon brush 23 for polishing the spool 24. The nylon brush 23 makes a linear reciprocating motion under the drive of the power transmission mechanism. The nylon brush 23 and the slid 24 surface contact, the discharge device is set at the bottom of the processed spool 24, the power transmission mechanism, the feed device, and the discharge device are respectively connected to the electric control system through the PLC; the electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com