Cross folding device used for handkerchief paper packaging, and implement method thereof

A technology of handkerchief paper and horizontal folding, which is applied in the packaging, packaging, transportation and packaging of paper products, can solve the problems of low profit of handkerchief paper, and achieve the effect of high production automation, improved efficiency and improved mechanical automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

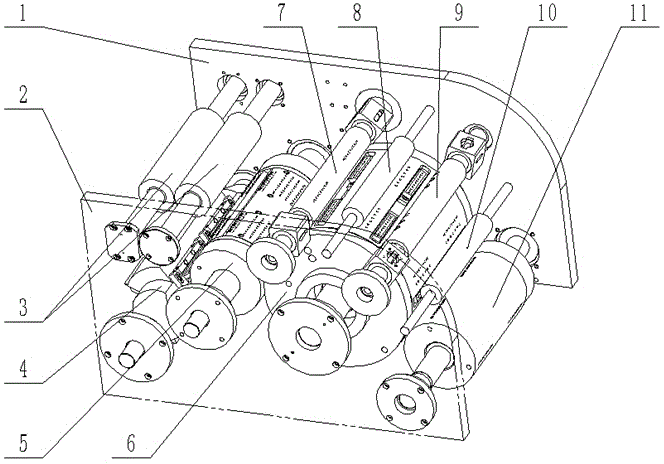

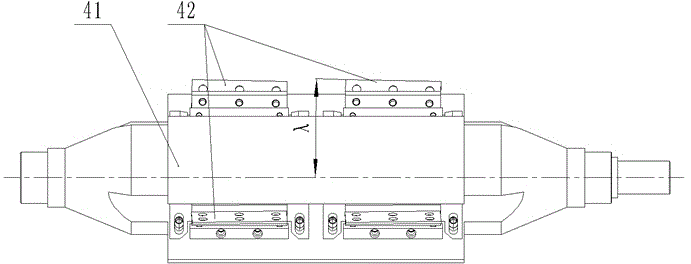

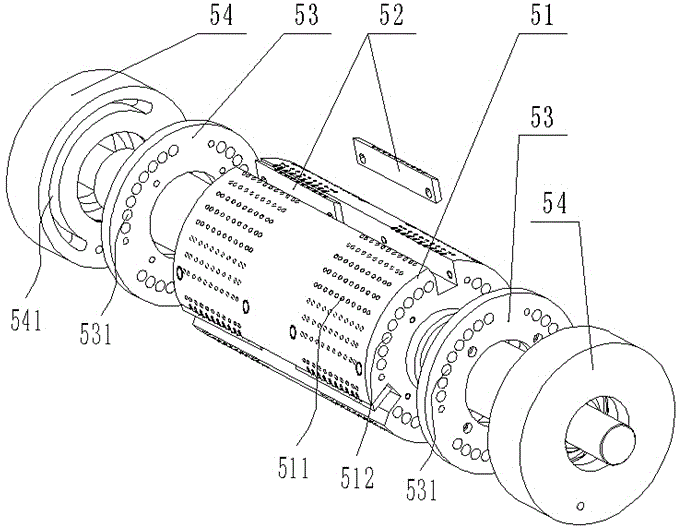

[0035] Such as figure 1 , a horizontal folding device for handkerchief paper packaging, including friction roller 3, cutter seat 4, cutter roller 5, paper suction roller 6, first folding roller 7, first folding pressure roller 8, second folding roller 9, Two-fold pressing roller 10, transfer roller 11, front side plate 2, rear side plate 1 and several bearings; described friction roller 3, cutter seat 4, cutter roller 5, paper suction roller 6, first folding roller 7 , two folding rollers 9, and transfer rollers 11 are all fixed between the front side plate 2 and the rear side plate 1 through bearings; between the boards 1, and the first and second folding rollers on it can rotate around their respective axes; the friction roller 3 is located at the front end of the drive chain of the device, and the handkerchief paper enters the device through the friction roller 3 , the mechanisms that pass through in turn are the cutter seat 4 and the cutter roller 5, the suction roller 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com