Device and method for monitoring dynamic contact status between multi-layer winding steel wire rope and winding drum of extradeep well

A dynamic contact and wire rope technology, applied in hoisting devices, applying stable tension/pressure to test the strength of materials, spring mechanisms, etc., can solve problems such as dynamic contact stress cannot be considered, and achieve the effect of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further explained below in conjunction with the accompanying drawings.

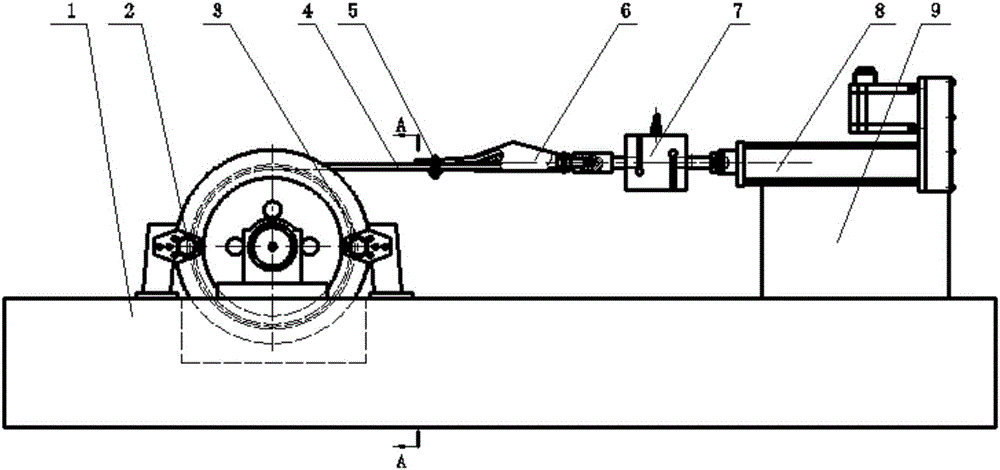

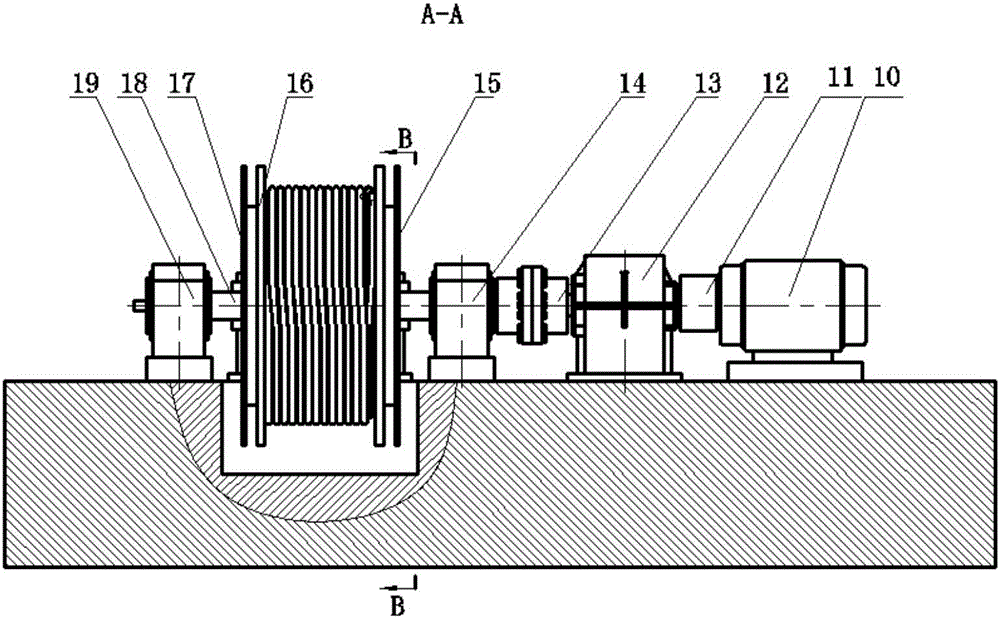

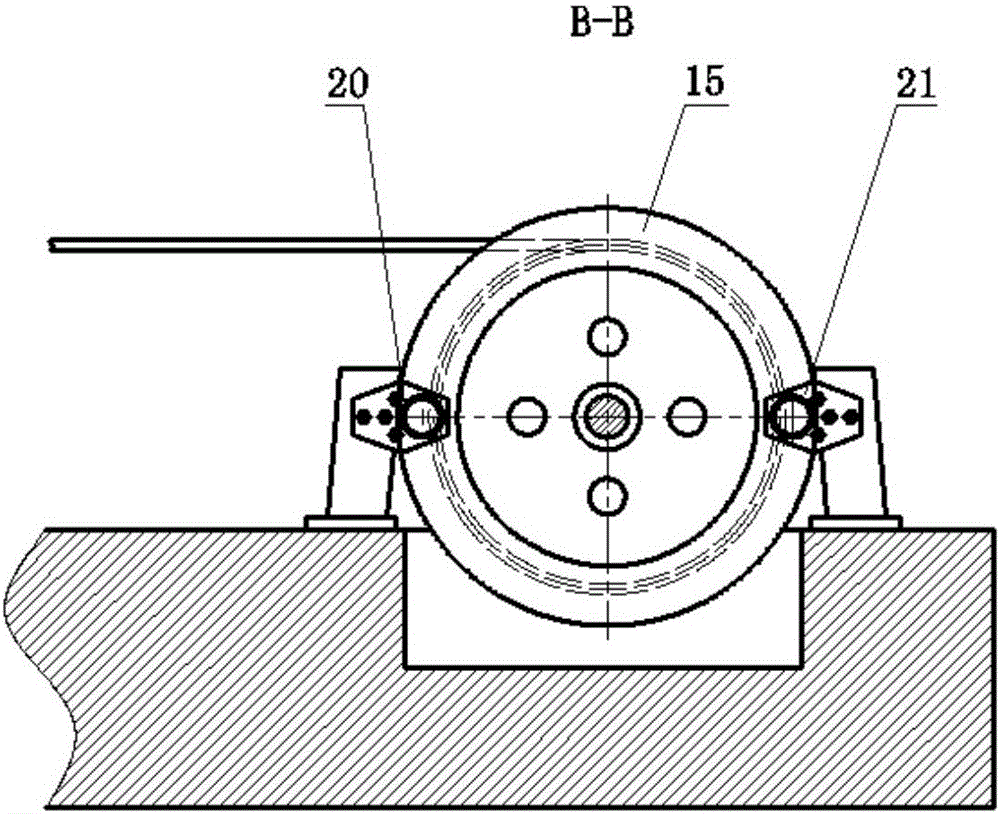

[0032] Such as Figures 1 to 11 As shown, a dynamic contact state monitoring device for ultra-deep well multi-layer winding steel wire rope and drum, including a support system, a winding system, a dynamic loading monitoring system, and a stress monitoring system.

[0033] The support system includes a base plate 1 and a servo electric cylinder support 9 , and the servo electric cylinder support 9 is fixed on the base plate 1 .

[0034] The winding system includes a motor 10, a high-speed cascade shaft 11, a reducer 12, a low-speed cascade shaft 13, a bearing seat A14, a friction disc A15, a disc brake A20, a disc brake B21, a main shaft 18, and a double-fold coil Tube 16, friction disc B17, disc brake C3, disc brake D2, bearing seat B19, steel wire rope 4. The motor 10 is fixed on the base plate 1, the output shaft of the motor 10 is connected to the input end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com