Linear heating source

A heating source, linear technology, used in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of inability to adjust the distribution of vapor deposition material gas, easy blockage of pore size, etc., to avoid uniformity reduction, The effect of preventing the blockage of the air outlet and reducing the maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

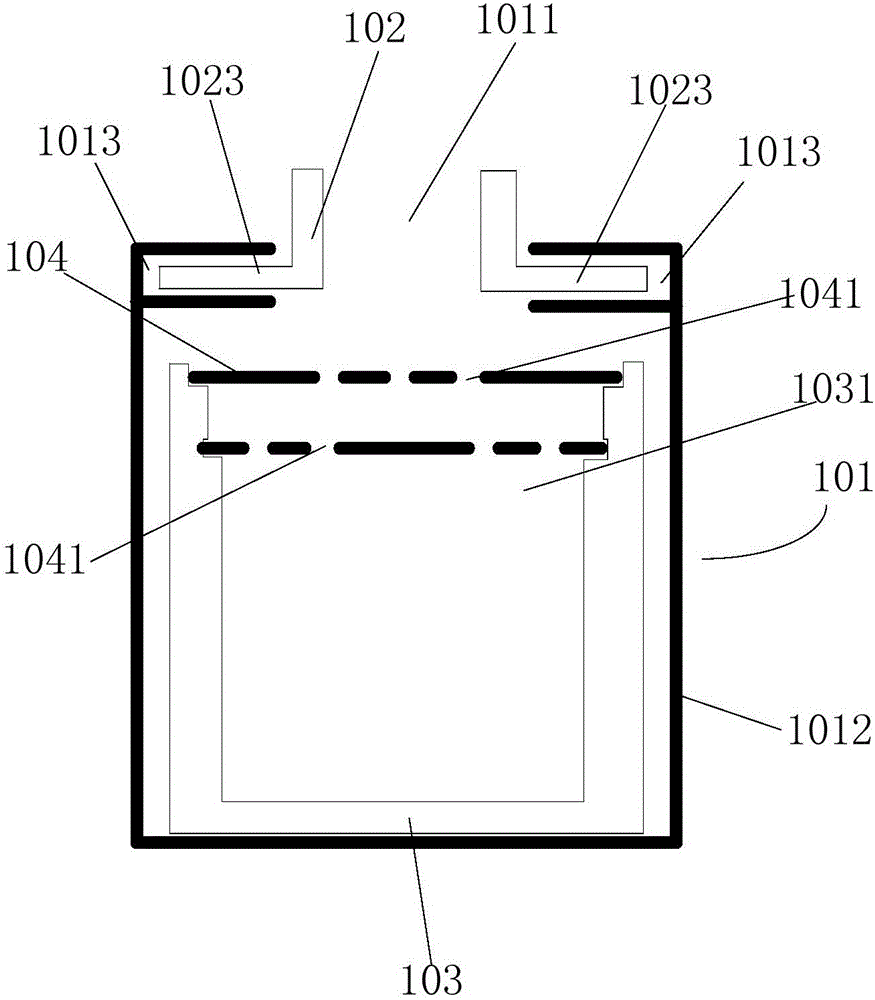

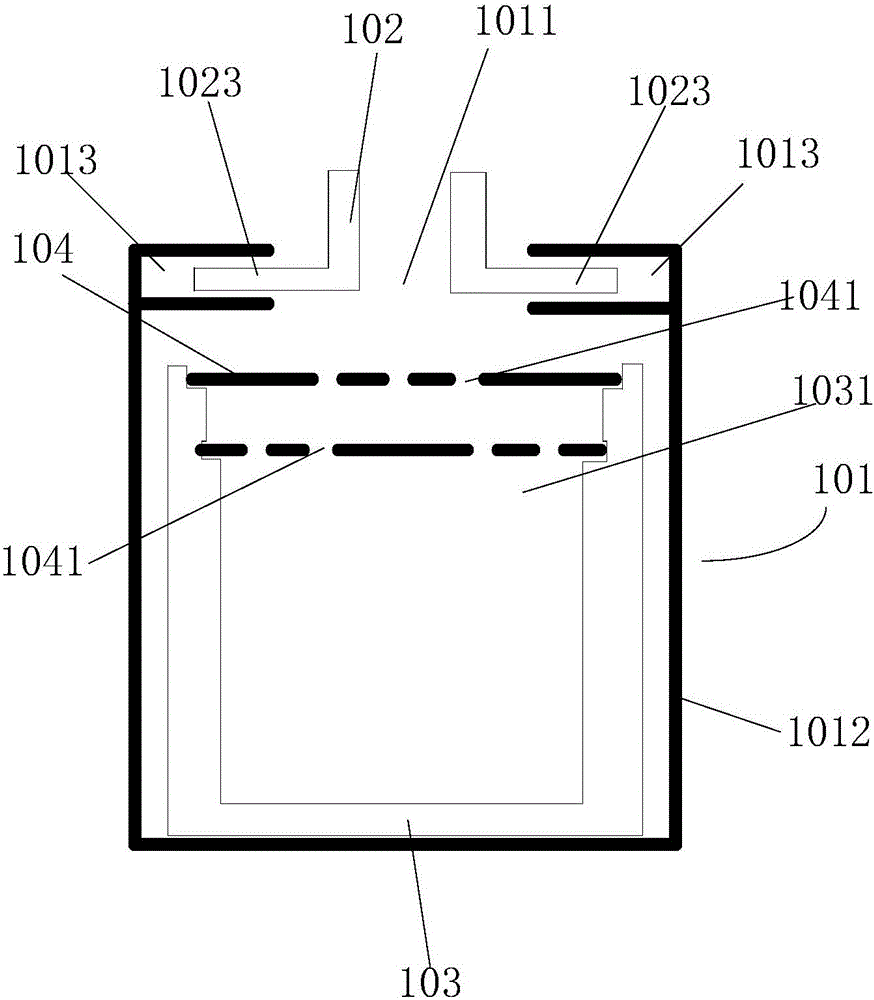

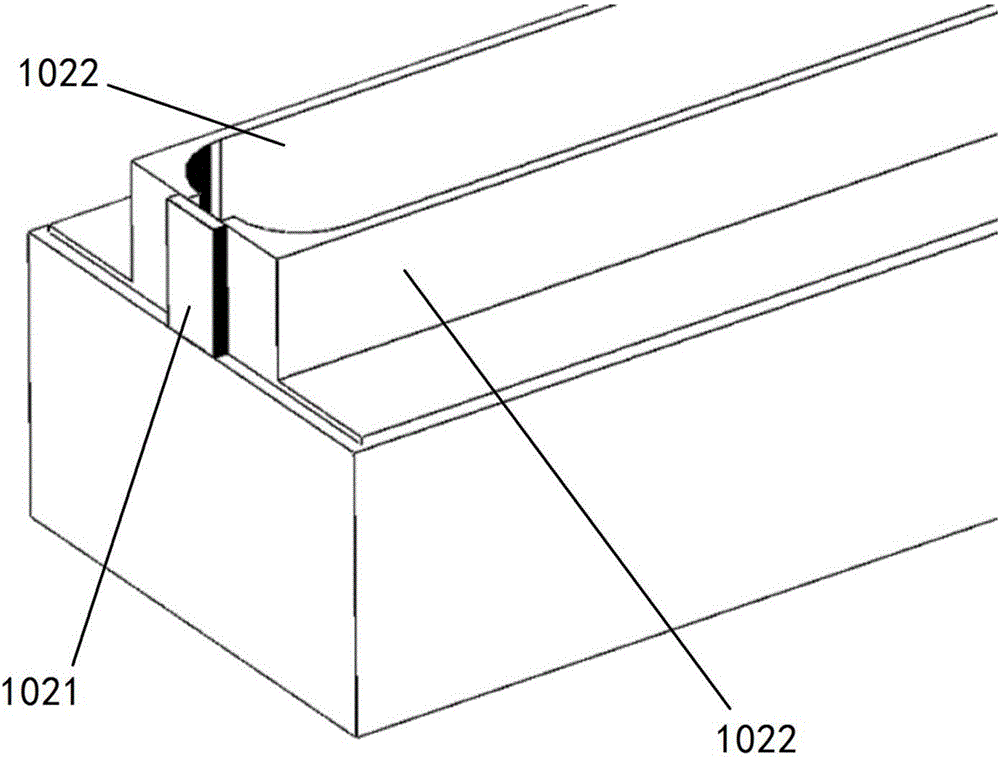

[0025] The present invention firstly provides a linear heating source, such as Figure 1A , 1B As shown, there is a heating chamber 101 having an air outlet part 102 with an adjustable air outlet, for example, which can be obtained from Figure 1A The larger width shown adjusts to the Figure 1B The smaller width shown, the gas outlet is used to allow the gas containing the vapor deposition material to pass through.

[0026] In the linear heating source provided by the embodiment of the present invention, the width of the gas outlet can be adjusted, so that the linear heating source can adjust the gas distribution of the evaporation material, and expand the applicable range of the linear heating source; at the same time, when cleaning the gas outlet part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com