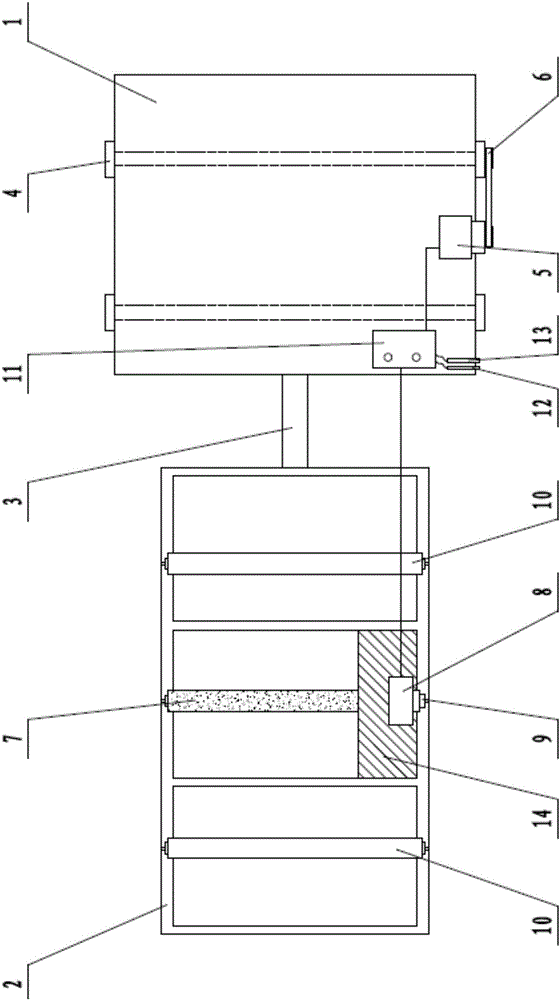

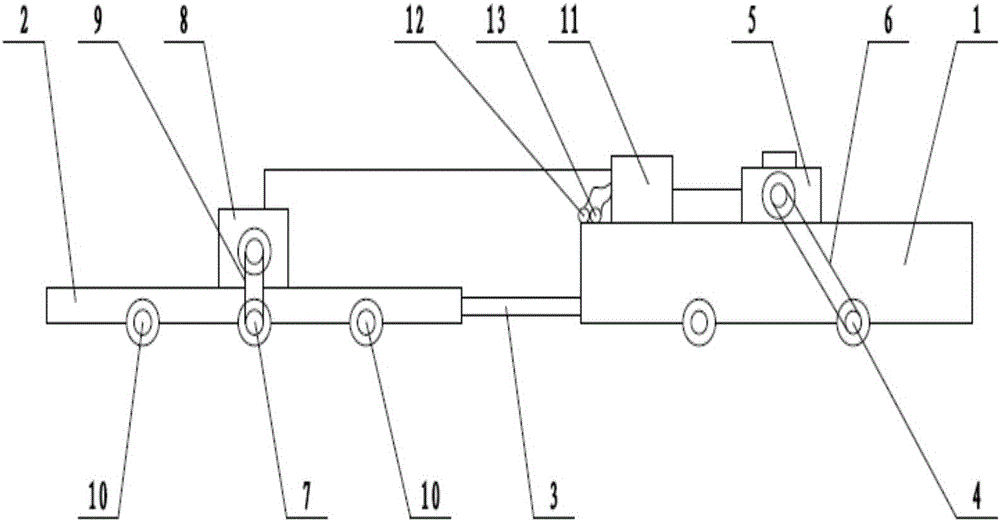

Full-automatic airfield pavement concrete three-roller grout lifting, grout kneading and leveling integrated machine

A concrete and fully automatic technology, applied in the direction of roads, roads, road repairs, etc., can solve the problems of low construction efficiency and high labor intensity, and achieve the effect of reducing labor intensity and improving construction efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] Embodiment: Start the control system 11, the speed regulating motor 5 controls the rotation of the transmission chain 6, drives the traveling wheel 4 to rotate, drags the traveling vehicle 1 to move forward, and drives the three-roller fixed bracket 2 to move forward through the connecting device 3, vibrating The motor 8 controls the rotation of the vibrating drum 7, and the gravel inside the vibrating drum 7 also rotates, but the angular velocity is inconsistent, which causes the vibrating drum 7 to vibrate and carry out the pulp extraction process. The hollow drum 10 is driven to rotate for the kneading process, and the digital displacement sensor 12 measures Displacement value, when the displacement reaches the set value, the control system 11 controls the speed-regulating motor to reverse, and drives the whole device to move in the opposite direction to carry out the pulping and kneading process. The counter 13 counts the number of repetitions. When the number of repe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com