Super-long vertical unbonded prestress structure and assembling method thereof

A prestressed structure and assembly method technology, applied in the direction of erecting/assembling bridges, bridge parts, bridge materials, etc., can solve the problem that the overall vertical prestressing construction quality and construction efficiency cannot be guaranteed, and the strength of the finished rolled threaded steel bar itself is not enough Ideal, poor pipe grouting effect and other problems, to reduce the risk of man-made quality accidents, solve construction technical difficulties and quality hidden dangers, and improve the overall construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

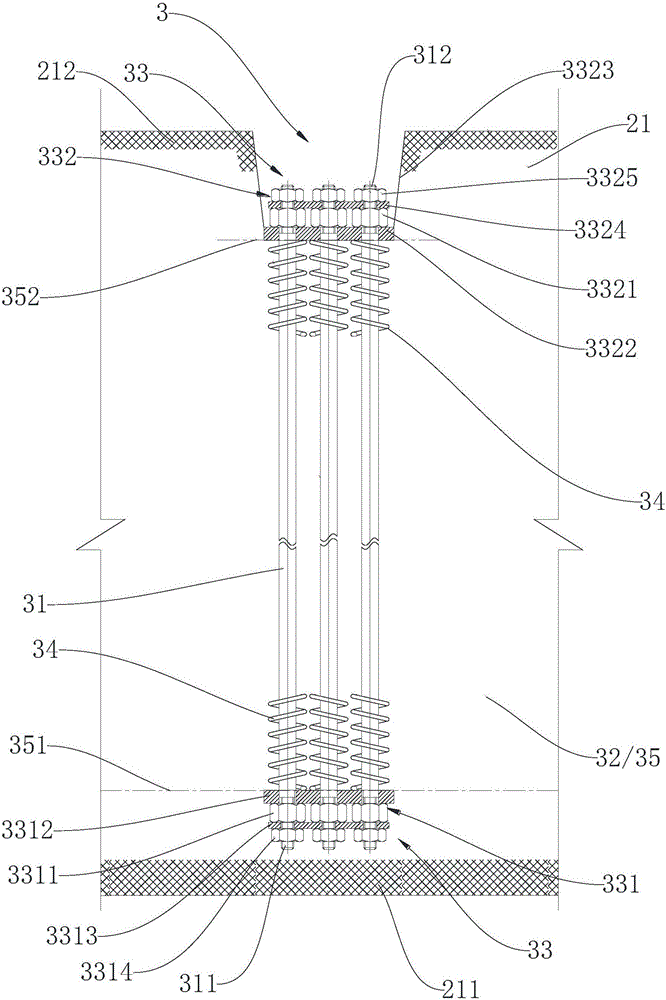

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

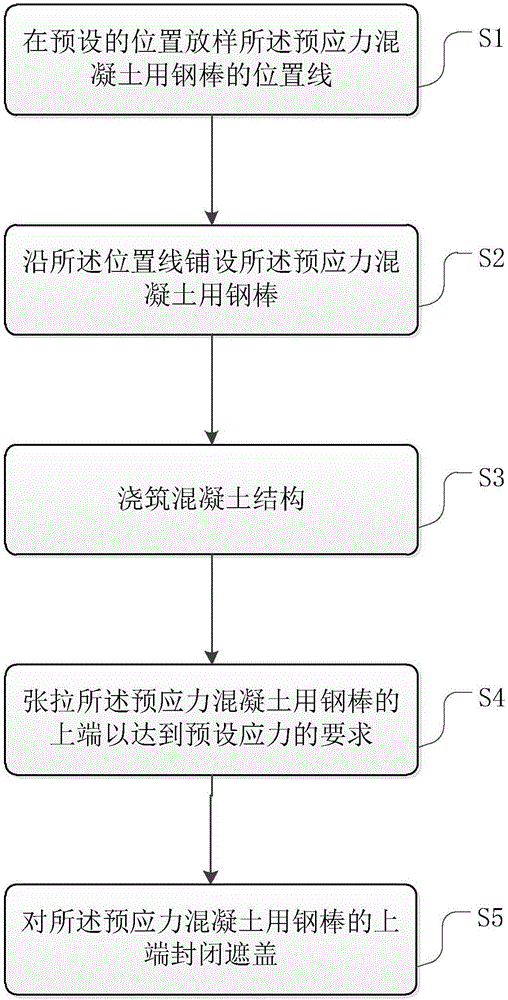

[0051] The ultra-long vertical unbonded prestressed structure of the present invention is mainly used in the 0# block of the main beam of the bridge, refer to figure 1 , the assembly steps are as follows:

[0052] (1) Stakeout position line.

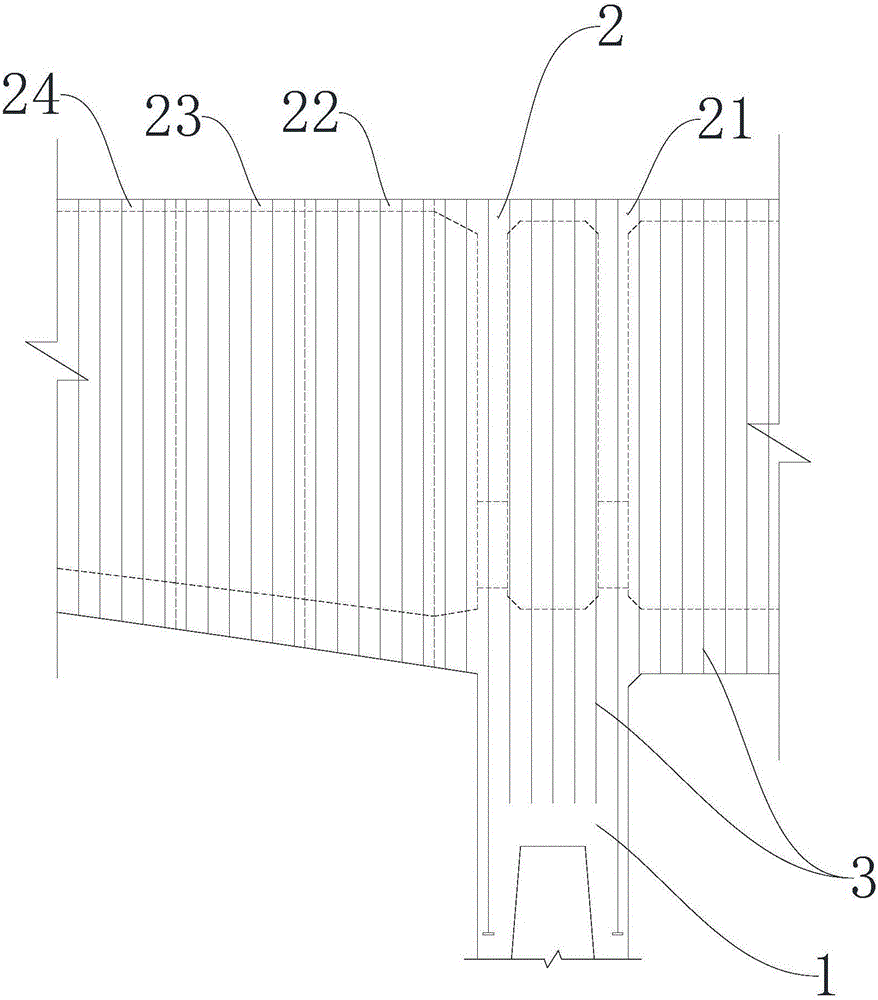

[0053] refer to figure 2, usually, the 0# block 21 of the main girder 2 above the main pier 1 of the bridge, with the 0# block 21 as the starting point, will successively extend the 1# block 22, the 2# block 23, the 3# block 24, etc. etc., the several segments are assembled to form the whole main beam 2 . When the main pier 1 is constructed to a short distance (for example, 2 meters) from the preset top surface of the main pier 1, the construction support of the 0# block 21 of the main beam 2 is set up for the purpose of supporting the main pier 1. The 0# block 21 is under construction, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com