A construction method of rectangular steel lining for water conservancy and hydropower engineering dams

A technology of water conservancy and hydropower and construction methods, applied in water conservancy projects, sea area projects, artificial waterways, etc., can solve the problems of overall project progress and management adverse effects, long construction period of steel lining parts, lagging construction period, etc., to reduce the possibility of component omission , Reduce the amount of manual work and save time during the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

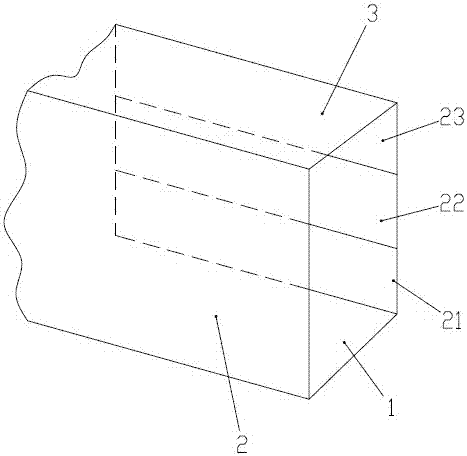

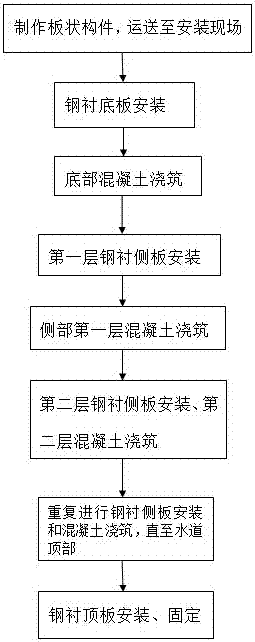

[0040] In this embodiment, the construction method of the rectangular steel lining is used for the installation of the rectangular steel lining in the hydroelectric project dam, as figure 1 with figure 2 As shown, the rectangular steel lining includes a steel backing plate 1, a steel lining side plate 2 and a steel lining top plate 3, and the steel lining side plate 2 is divided into three layers for construction in accordance with the construction method and the size of the dam’s flow channel. They are the first layer of steel-lined side panels 21, the second layer of steel-lined side panels 22 and the third layer of steel-lined side panels 23. The specific construction steps are as follows:

[0041] (1) Firstly, the steel plates that make up the rectangular steel lining are made into multiple plate-shaped component units and transported to the installation site; in this process, the height and layered layers of the rectangular steel lining are determined in advance accordi...

Embodiment 2

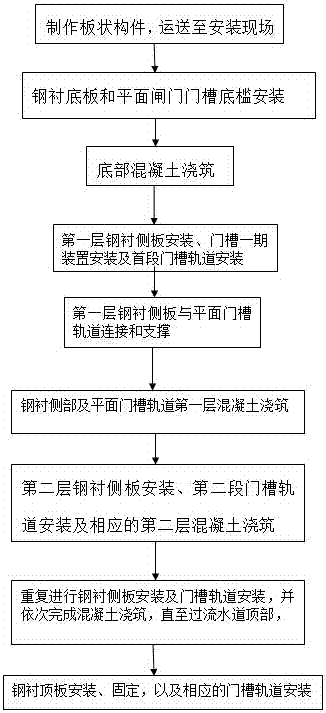

[0058] This embodiment is applied to the installation of rectangular steel linings in hydropower project dams. In this embodiment, the construction of rectangular steel linings is combined with the installation of plane gate slots. image 3 As shown, the specific construction steps are as follows:

[0059] (1) Firstly, the steel plates that make up the rectangular steel lining are made into multiple plate-shaped component units and transported to the installation site; in this process, the height and layered layers of the rectangular steel lining are determined in advance according to the concrete process of the dam In this embodiment, the steel-lined side plate is divided into three layers for construction, and then the size of the plate-shaped member is determined, and the corresponding plate-shaped components are transported and hoisted in sequence according to the order of forming the steel-lined plate, steel-lined side plate and steel-lined top plate to the construction s...

Embodiment 3

[0072] This embodiment is applied to the installation of rectangular steel linings in hydropower project dams. In this embodiment, the construction of rectangular steel linings is combined with the installation of arc-shaped gate slots. Figure 4 As shown, the specific construction steps are as follows:

[0073] (1) Firstly, the steel plates that make up the rectangular steel lining are made into multiple plate-shaped component units and transported to the installation site; in this process, the height and layered layers of the rectangular steel lining are determined in advance according to the concrete process of the dam In this embodiment, the steel-lined side plate is divided into four layers of construction, and then the size of the plate-shaped member is determined, and the corresponding plate-shaped components are transported and hoisted in sequence according to the order of forming the steel-lined plate, steel-lined side plate and steel-lined top plate to the constructi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com