Installation method for anti-floating overall template of water collection pit

An installation method and technology of integral formwork, applied in construction, infrastructure engineering and other directions, can solve the problems of non-conforming green environmental protection construction, destruction of natural environment resources, less turnover of plywood, etc., to achieve simple and convenient assembly and dismantling of formwork, and reduce construction costs. , to avoid the effect of rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

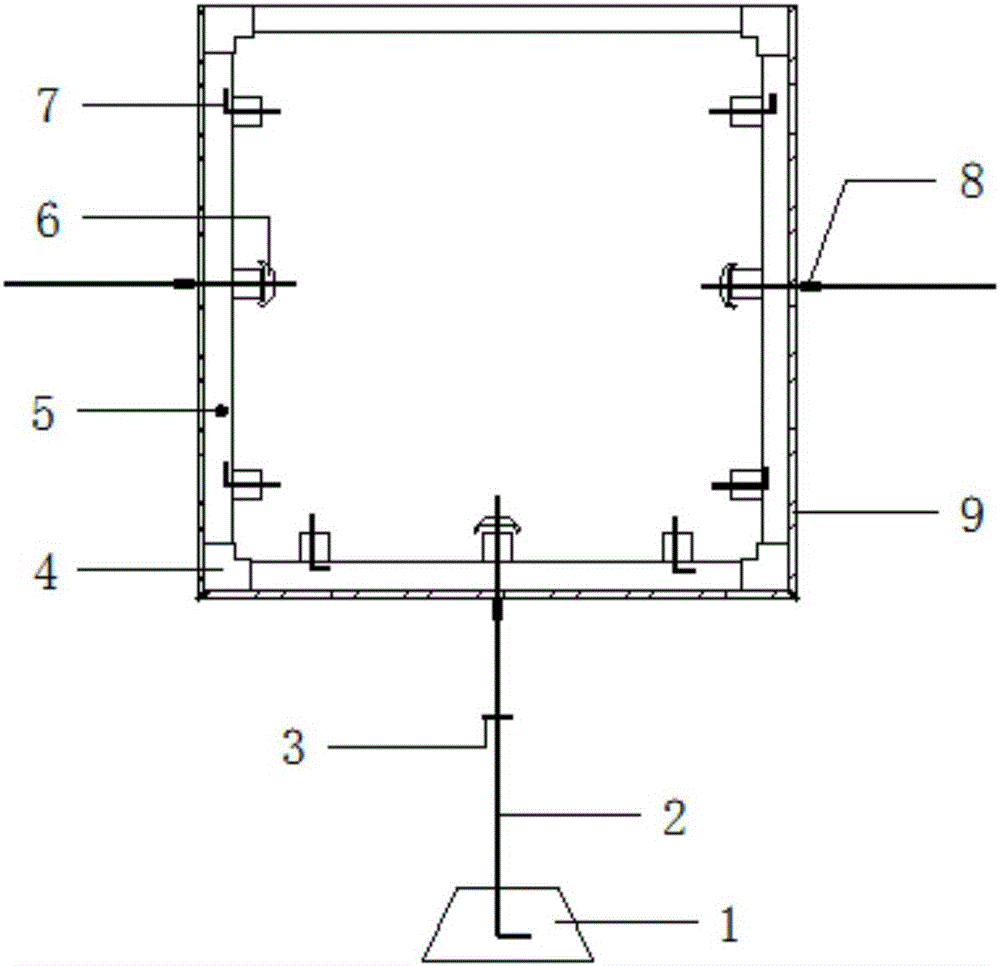

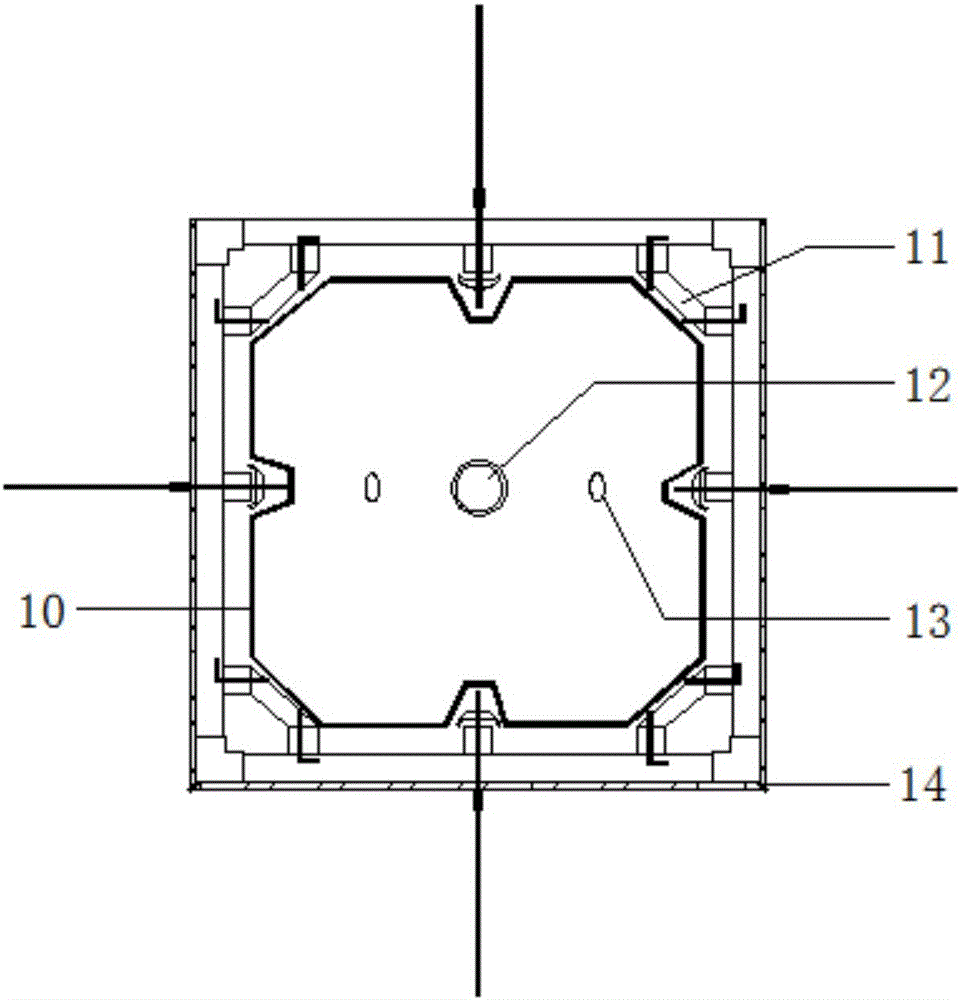

[0016] Example: such as Figure 1-2 As shown, the present invention is an installation method of a sump anti-floating integral formwork,

[0017] Step 1: Preliminary preparation, excavate a splayed groove at the bottom of the sump when excavating the foundation earthwork, bury the fixed tie rod 2 of the water stop ring 3 before pouring the cushion layer 1, and pour the splayed groove at the same time when pouring the cushion layer .

[0018] Step 2: On-site assembly, cut the PVC formwork according to the size of the sump interface, fix the square pipe 5 to the PVC formwork 9, fix the soft plastic bead 14 at the corner joint of the PVC formwork 9, and use a stretchable The steel angle collar 4 connects the square pipe 5, and the telescopic steel angle collar 4 can compress a soft plastic bead 14; the second floor square pipe 5 is fixed to the first floor square pipe 5 by using the fixed insert rod 7, The template assembly is complete.

[0019] Step 3: On-site installation. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com