Spill hole retainer assembly for bathroom sanitary apparatuses and bathroom sanitary apparatus

A technology for overflow holes and equipment, which is applied in the field of sanitary equipment, can solve problems such as not being suitable for consumers to replace baffles by themselves, high processing precision requirements, and affecting decorative aesthetics, etc., to achieve stable connection, improve decorative aesthetics, The effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

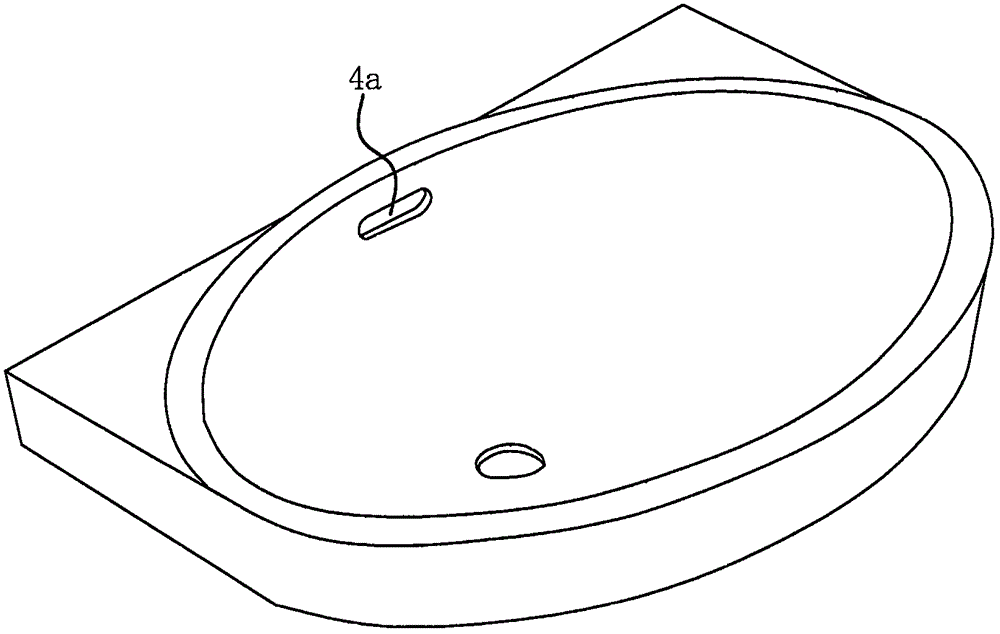

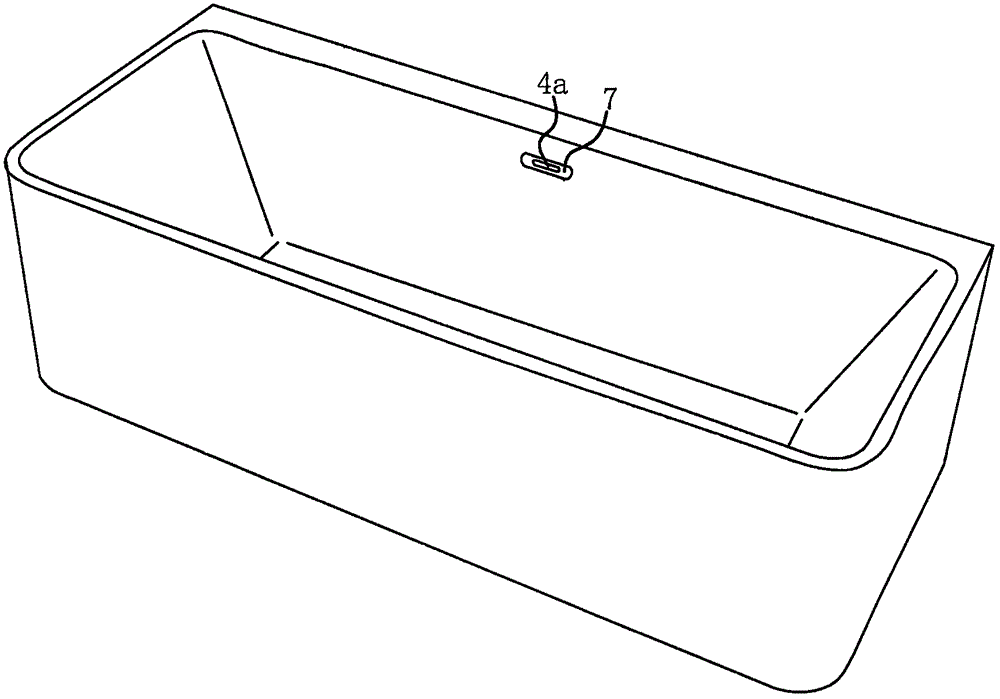

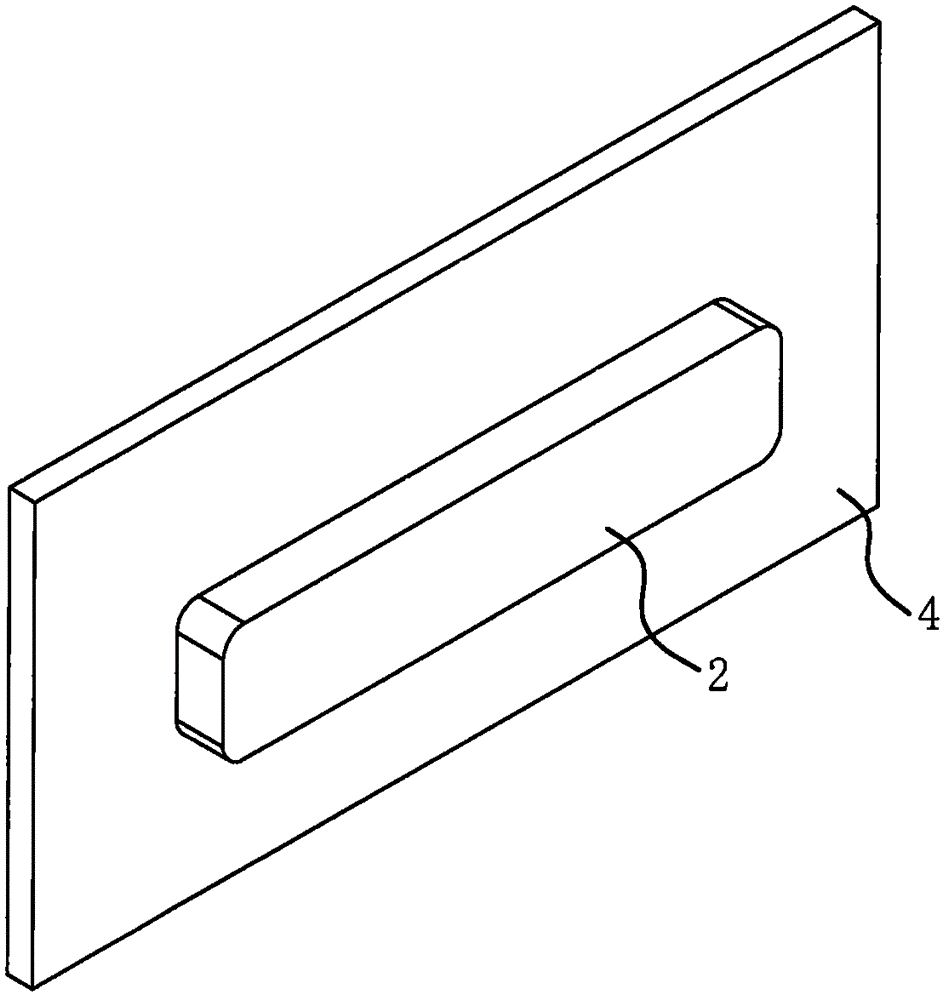

[0031] like Figure 3 to Figure 8 As shown, the overflow hole baffle assembly of the sanitary equipment includes a mounting base 1 and a baffle 2 . The blocking plate 2 is in the shape of a strip plate.

[0032] Mounting seat 1 is a basic component, and the number of mounting seat 1 is one; The mounting base 1 is compatible with the blocking plate 2, and the length and width of the mounting base 1 are smaller than the length and width of the blocking plate 2. Both ends of the mounting base 1 are provided with strip-shaped connecting grooves 1b, and two strip-shaped connecting grooves 1b are arranged perpendicularly to each other.

[0033] A mounting groove 2a is formed on the back of the blocking piece 2, and the mounting groove 2a is strip-shaped. A water inlet 2b communicating with the installation groove 2a is opened on the lower side of the blocking piece 2; the water inlet 2b is also strip-shaped. A hanging groove 2c extending longitudinally along the installation gro...

Embodiment 2

[0040] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be redundantly described, and only the differences will be described, and the differences are as follows: Figure 9 and Figure 10 As shown, the water inlet 2b on the baffle 2 is located on the front surface of the baffle 2 .

Embodiment 3

[0042] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be redundantly described, and only the differences will be described, and the differences are as follows: Figure 11As shown, the number of mounting bases 1 is two. The mounting base 1 is block-shaped, and the accompanying drawings in the manual Figure 11 It is given that the cross section of the mounting seat 1 is a regular hexagon; according to actual conditions, the cross section of the mounting seat 1 may also be a regular quadrilateral.

[0043] There is only one bar-shaped connecting groove 1b on each mounting base 1; the two mounting bases 1 are respectively located at both ends of the overflow hole 4a, that is, the corrugated parts 1a on the two mounting bases 1 are respectively embedded in the two ends of the hanging groove 2c Ministry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com