A front and back injection type polycrystalline composite single cone bit

A single-cone, jetting technology, used in drill bits, earth-moving drilling, drilling equipment, etc., can solve the problems of poor reliability of fastened composite teeth, difficult to control brazing temperature, and small volume of cones, and achieve the effect of diameter protection. Good, improve the working index of the drill bit, and strengthen the effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

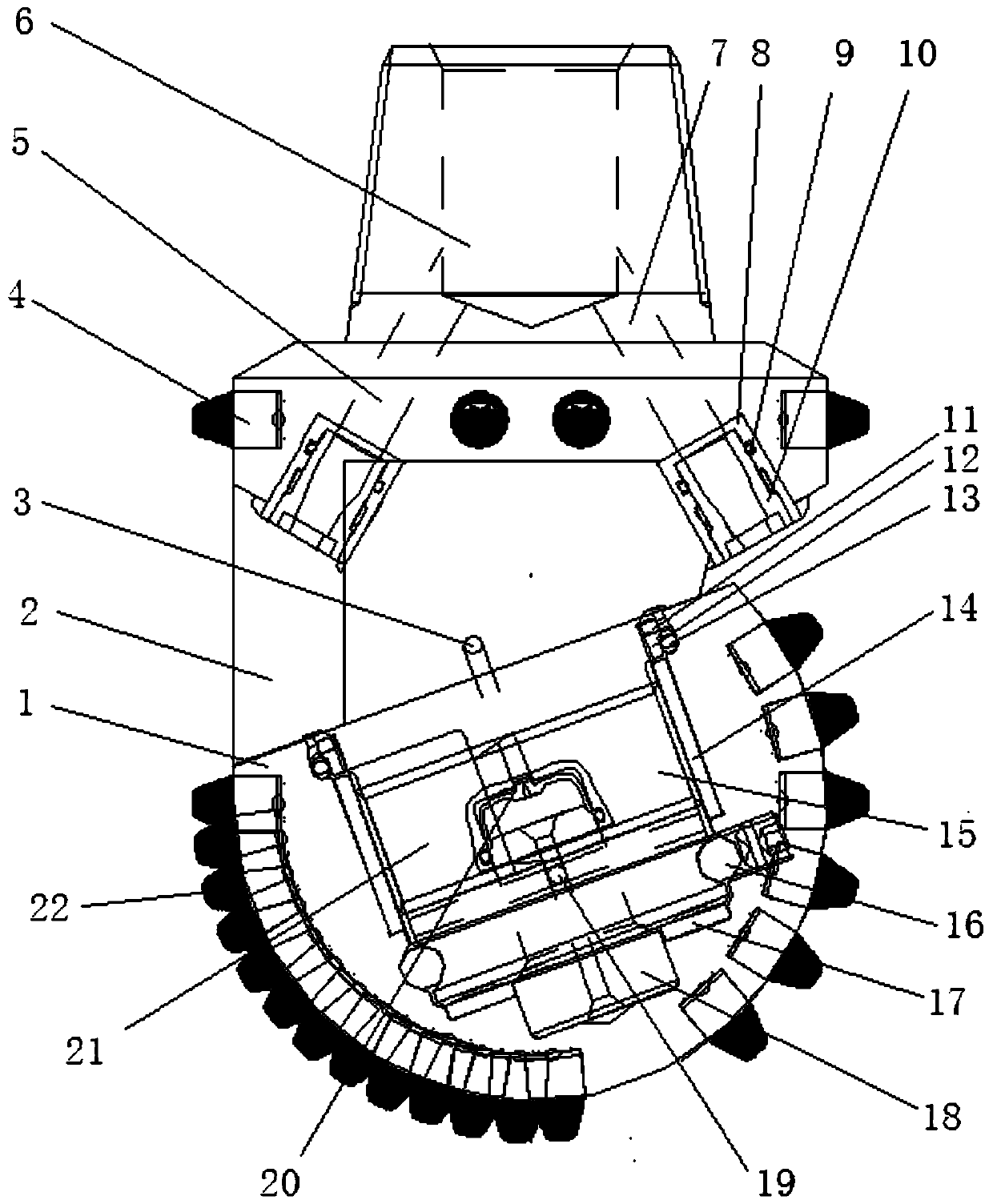

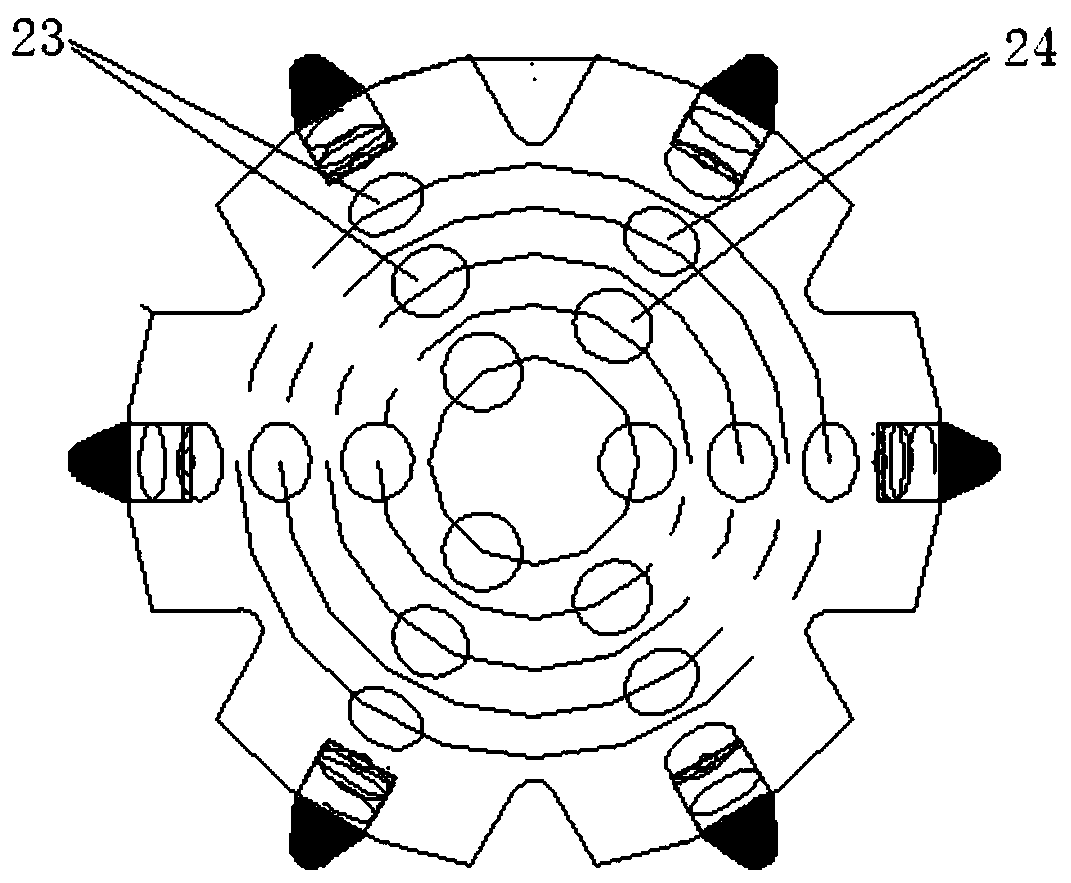

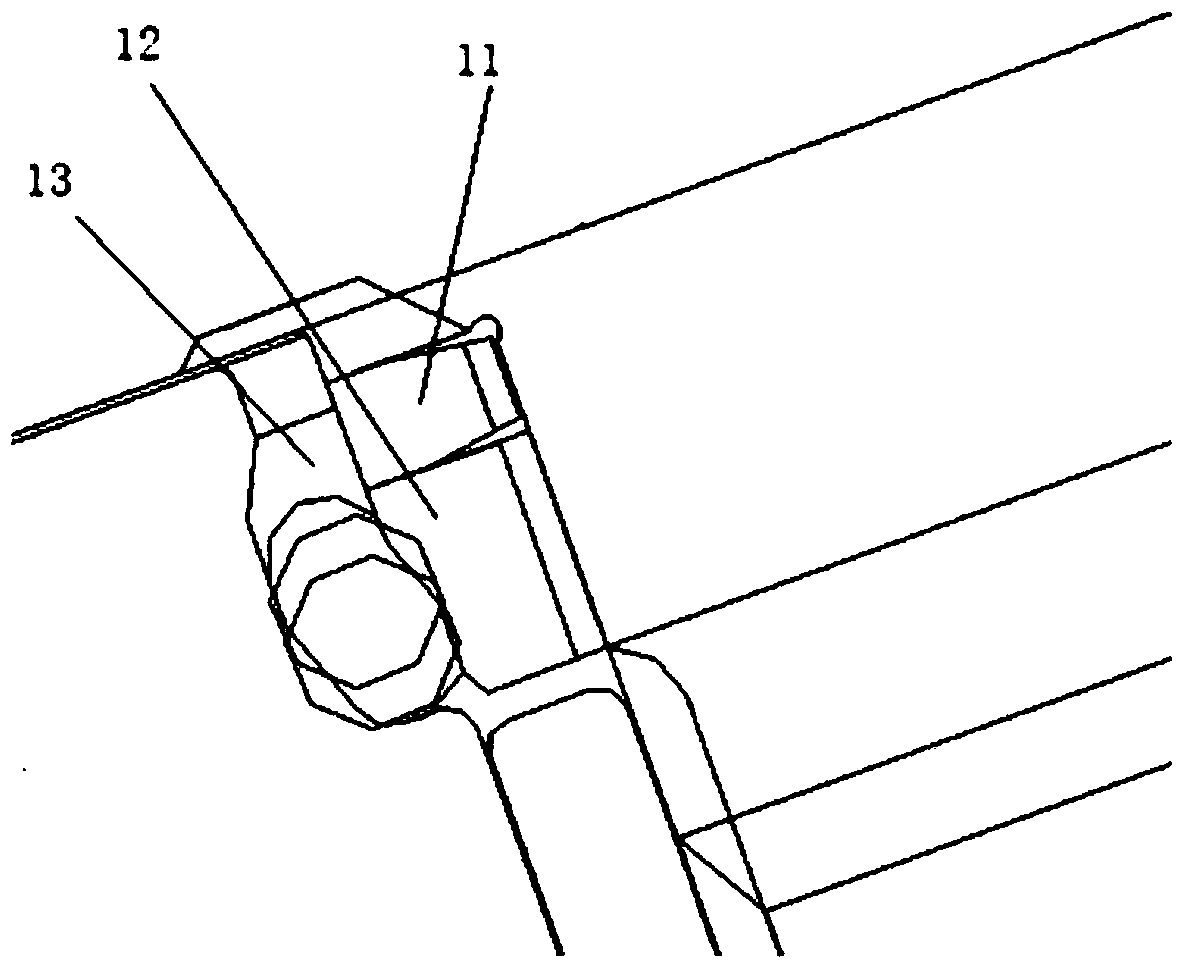

[0026] refer to figure 1 , a schematic diagram of the structure of a front and rear injection type polycrystalline composite single cone bit of the present invention, the end of the bit base 2 is provided with a large shaft 15 protruding obliquely inward, the large shaft 15 is provided with a cone 1, and the bit base 2 The interior of the water injection hole 6 and the forward inclined water hole 7 and the rearward inclined water hole 5 communicated with the water injection hole 6 are provided. 15 tends to be opposite. A nozzle 10 is respectively installed in the front stretching inclined water hole 7 and the rear stretching inclined water hole 5 , and a nozzle cover 8 is arranged outside the nozzle 10 , and a nozzle sealing ring 9 is installed between the nozzle cover 8 and the nozzle 10 .

[0027] The high-speed mud sprayed from the forward inclined water hole 7 is sprayed on both sides of the cone 1, cleaning the cone 1 and carrying the bottom cuttings back up; the high-sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com