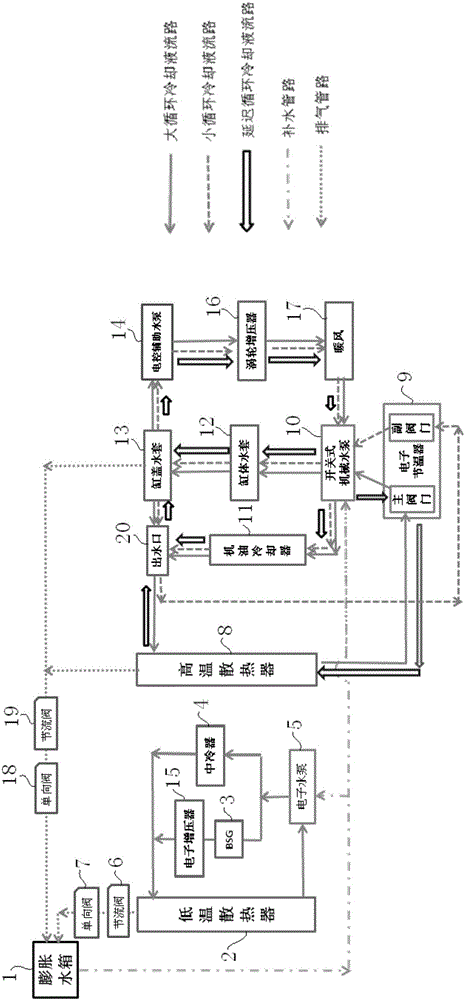

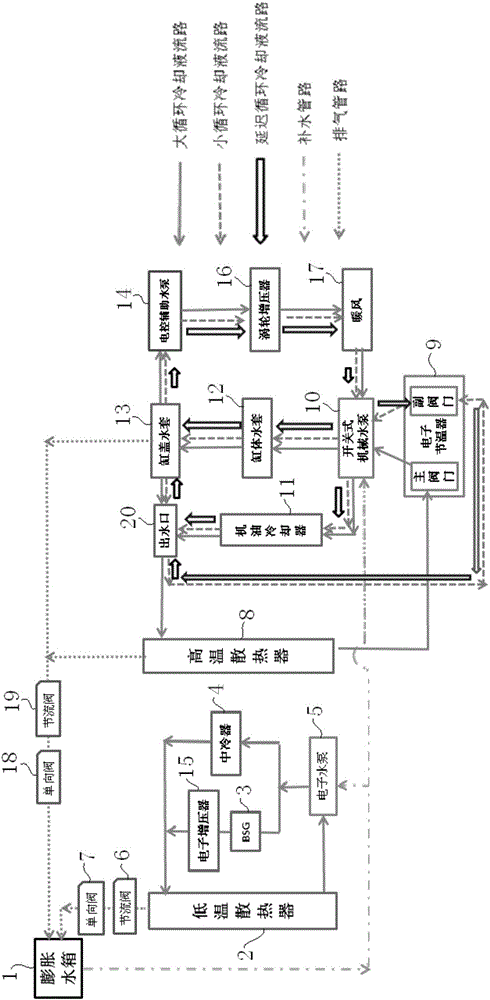

Engine cooling system adopting electronic control-assisted water pump

An engine cooling and auxiliary water pump technology, which is applied to engine cooling, engine components, combustion engines, etc., can solve the problems of high thermal balance risk, difficult layout, slow response, etc., to ensure intake air temperature and intake efficiency, improve Warm air effect and dynamic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

[0032] Definition of key components

[0033] BSG: (Belt Starter Generator) A belt starter generator system: it can realize engine start / stop function, energy recovery, auxiliary torque increase and other functions.

[0034] Electronic water pump: a motor-driven water pump that uses piezoelectric materials as a power device, which can realize electronic control from drive, and uses an electronic integrated system to control liquid transmission to achieve adjustability and accuracy of liquid transportation.

[0035] High-temperature radiator: The radiator is a part of the car cooling system. It is mainly composed of water inlet chamber, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com