Hydropower station optimized operation control method and system

A control method and a technology for optimizing operation, which can be applied to control system purposes, hydroelectric power generation, and control multiple engines at the same time, and can solve problems such as high labor cost investment, high cost, and high equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

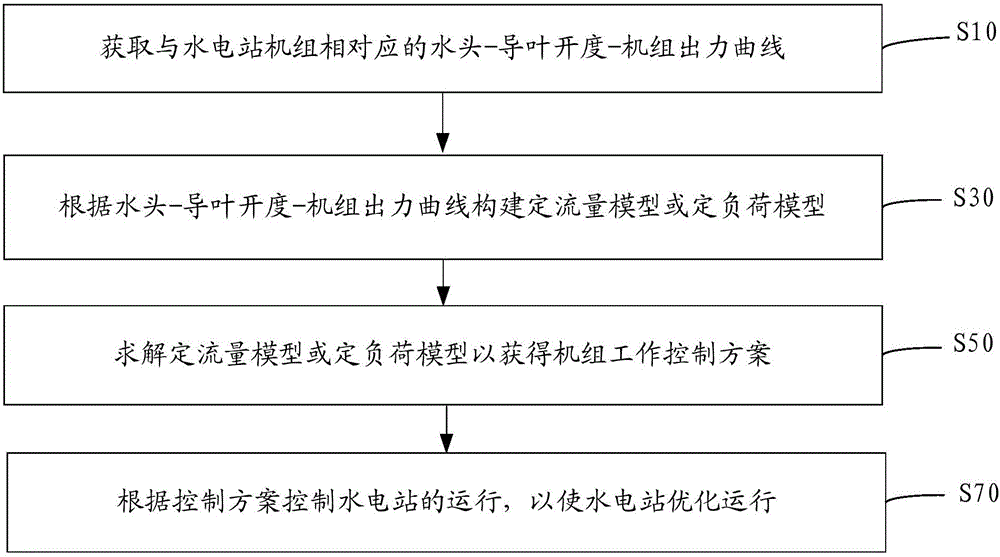

[0093] like figure 1 As shown, a hydropower station optimization operation control method, including:

[0094] S10: Obtain the water head-guide vane opening-unit output curve corresponding to the hydropower unit.

[0095] Through the experiment on the hydropower unit, the corresponding water head-guide vane opening-unit output curve of the hydropower unit is obtained. The head-guide vane opening-unit output curve includes static head-guide vane opening-unit output curve or net water head-guide vane opening-unit output curve.

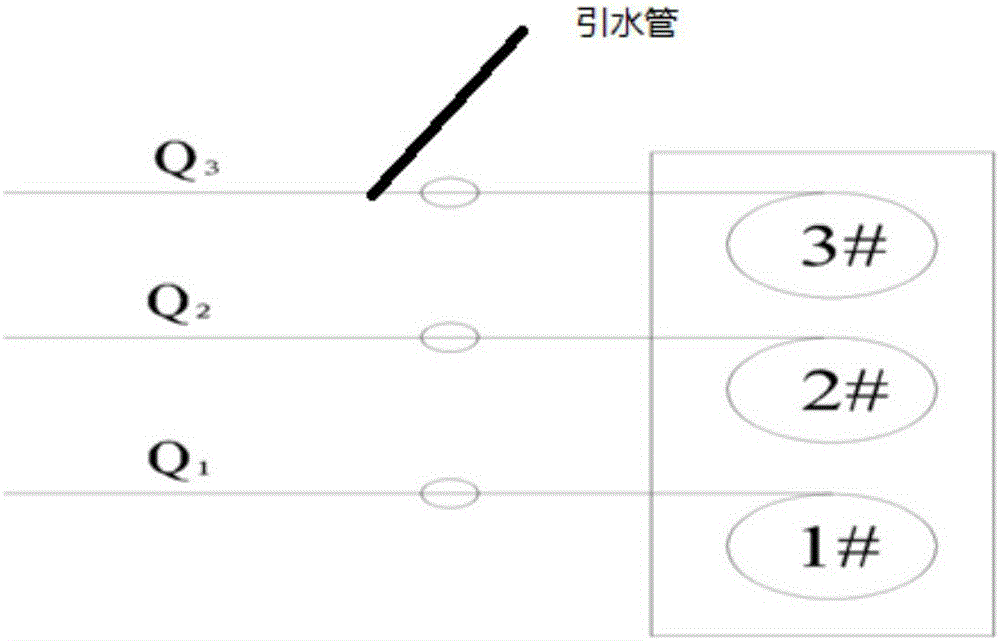

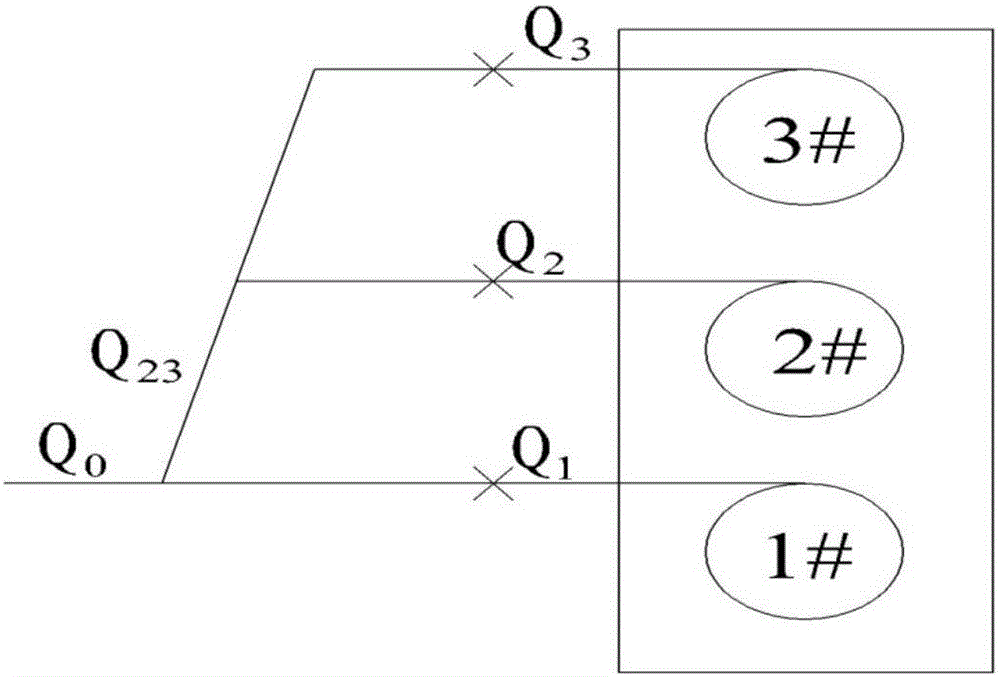

[0096] Hydropower stations can be divided into unit water supply hydropower stations and combined water supply hydropower stations. Unit water supply hydropower station, that is, one water diversion pipe for each unit, such as figure 2 As shown, the water flowing through the turbine in the hydropower station is connected to the turbine through the diversion pipe. The water head, the opening of the guide vane, and the flow through the unit are determi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com