Belt tensioning equipment of hybrid electric vehicle

A technology for hybrid vehicles and tensioning equipment, applied in mechanical equipment, belts/chains/gears, transmissions, etc., can solve the problems of expensive tensioners, high tension, and high structural costs, and achieve the effect of avoiding slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

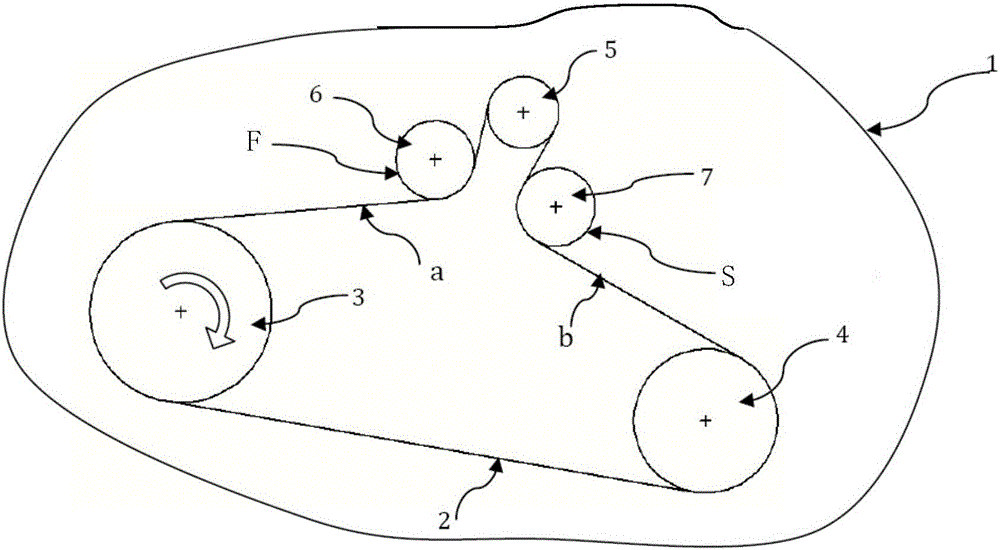

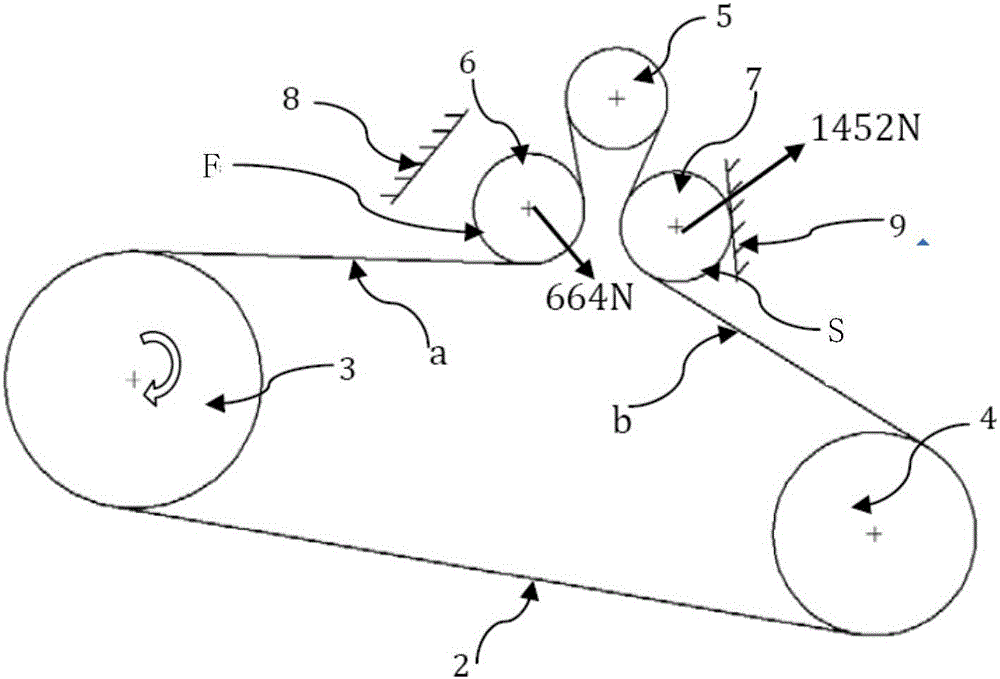

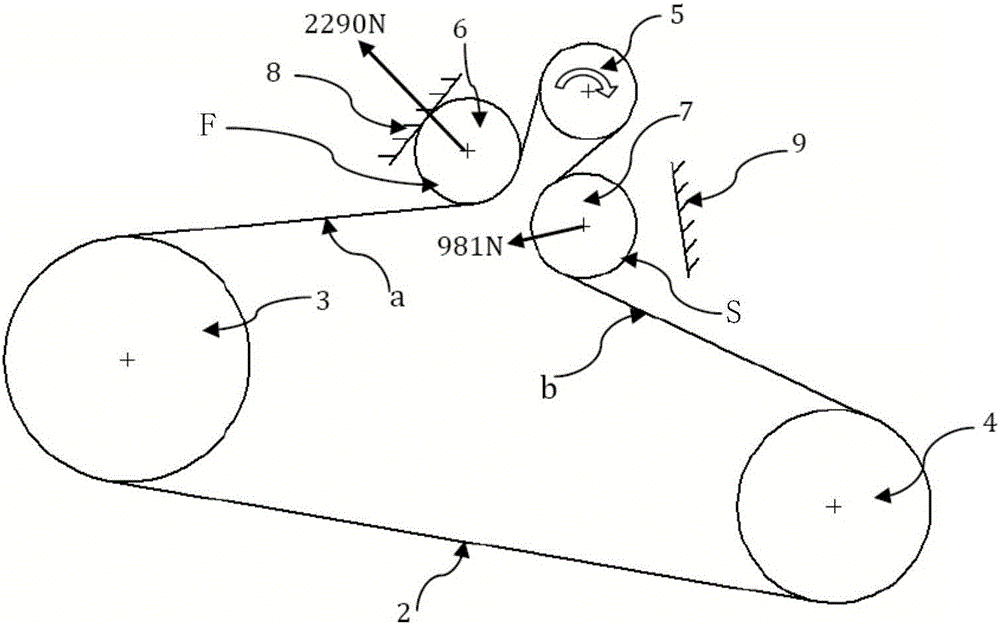

Embodiment 2

[0091] Figure 7-a , 7-b , 7-c is the second specific form of the hybrid vehicle belt tensioner of the present invention, which includes: a tensioner housing that has a cavity and is supported on the starter motor / generator; two tensioner pulleys , which loads the belt with a preload in front of and behind the pulley of the starter motor / generator in the direction of the belt loop; an arc-shaped spring generating the preload, which is housed in the cavity; a circular arc A tensioning arm, which is movably supported in the cavity in the plane of the arc, is loaded by the force of the spring on the one hand and supports one of the tensioner pulleys on the other hand; the tensioning arm The equipment also includes a stop device. There are two disconnected arc-shaped holes in the stop device. The number of the tension arm and the spring is two, and the two tension arms are arranged on the tensioner housing. In the cavity of the body, and the free end of each tension arm goes dee...

Embodiment 3

[0100] Figure 9 Another specific form of the invention is shown. The first tensioner 232 and the second tensioner 242 (in Figure 1-3 described as the first and second tensioners) are placed in positions that optimize the geometry of the wheel train. The two stop devices 82 and 92 are arranged according to an example of the invention. The position of the stop device on the tensioner is arranged differently according to the needs.

Embodiment 4

[0102] Figure 10 Another specific form of the invention is shown. Belt 2 is a synchronous conveyor belt (or timing belt), and the pulley can be a grooved pulley or a flat pulley. Also, in this case, the two stops will limit the movement of the tensioner. This solution can be used when the power / torque of the starter motor / generator is particularly large (close to or greater than 20KW). At the same time, the kinetic energy of the starter motor is not limited to start the engine, and the starter motor can also be used to drive the car for a certain kilometer number (micro-hybrid vehicle function).

[0103] It is necessary to mention an important situation concerning the transmission of the two tensioners that occurs on both sides of the generator: they separate the motion of the crankshaft and the generator. In fact, when the crankshaft decelerates, the moment of inertia of the generator tends to maintain the original speed and tension the band a ( figure 2 ) forces the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com