Stator bar sectional dimension detection system based on machine vision

A technology of stator bar and cross-sectional size, which is applied in the direction of instruments, measuring devices, and optical devices, can solve the problems of high labor cost, poor accuracy, and low efficiency, and achieve a high degree of automation, reduce labor costs, and improve accuracy and the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

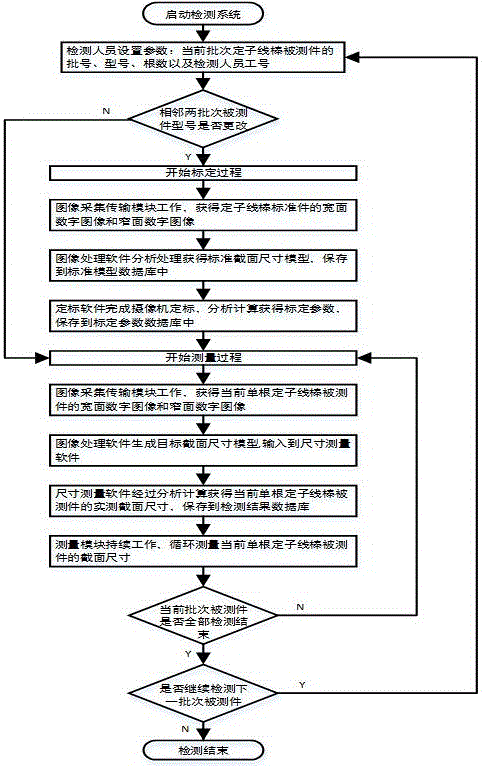

[0031] The present invention will be further described below in conjunction with drawings and embodiments.

[0032] The embodiment of the present invention provides a machine vision-based detection system for the section size of the stator bar, which can effectively detect and obtain the section size of the stator bar with high reliability. Each will be described in detail below.

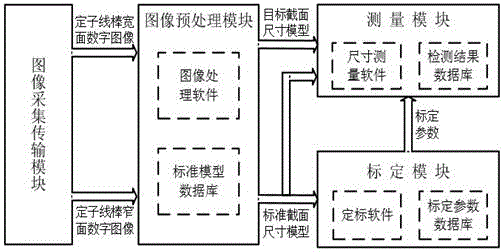

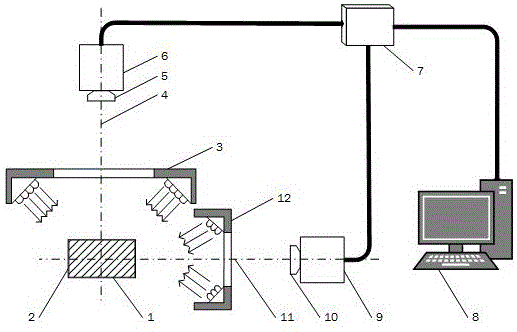

[0033] see figure 1 , figure 1 It is a diagram of the relationship between modules of a machine vision-based detection system for stator bar section size provided by the present invention. Specifically, the detection system in the embodiment of the present invention may include an image acquisition and transmission module, an image preprocessing module, a calibration module and measurement module; when the stator bar arrives at the measurement station, the image acquisition and transmission module collects the wide-face image and the narrow-face image of the stator bar in real time, and converts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com