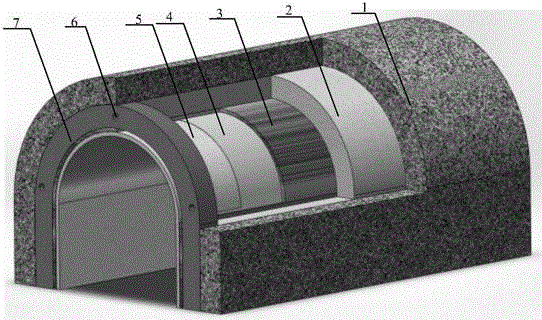

Large-size simulated roadway shotcrete supporting shotcrete layer loading method

A roadway and sprayed concrete technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of difficulty in ensuring accuracy, difficulty in determining numerical simulation parameters, and inability to realize roadway loads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The concrete implementation method of roadway loading method of the present invention is as follows:

[0009] 1. The basic parameters of the model. Concrete is a multi-phase composite material composed of coarse and fine aggregate, cement hydrate, unhydrated cement particles, etc., which contains a large number of micro-defects such as micro-pores and micro-cracks. The tensile and compressive properties of concrete are very different, and its compressive strength is much higher than the tensile strength. After the concrete roadway is formed, due to the action of gravity, the upper part of the roadway will generate a lateral pressure on the lower part, which is far less than the tensile strength after calculation and can be ignored. According to the basis provided by Ren Yu's article "Mechanical Properties and Engineering Application of Coal Mine Wet Shotcrete", when the concrete thickness is less than 80mm, the concrete thickness is relatively small, in the flexible st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com